Delem Da56s 100t CNC Hydraulic Press Brake 3.2m Length Sheet Metal Bending Machine

LZK CNC Machine Tool (Anhui) Manufacturing Co., Ltd.- Warranty:2-year

- Condition:New

Base Info

- Model NO.:MB8 100T3200

- Certification:ISO 9001:2000, CE, TUV

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

- Type:Press Brake

- CNC System:Delem Da56s

- Backgauge:Servo Motor, Ball Screw and Linear Guide

- Main Motor:Siemens

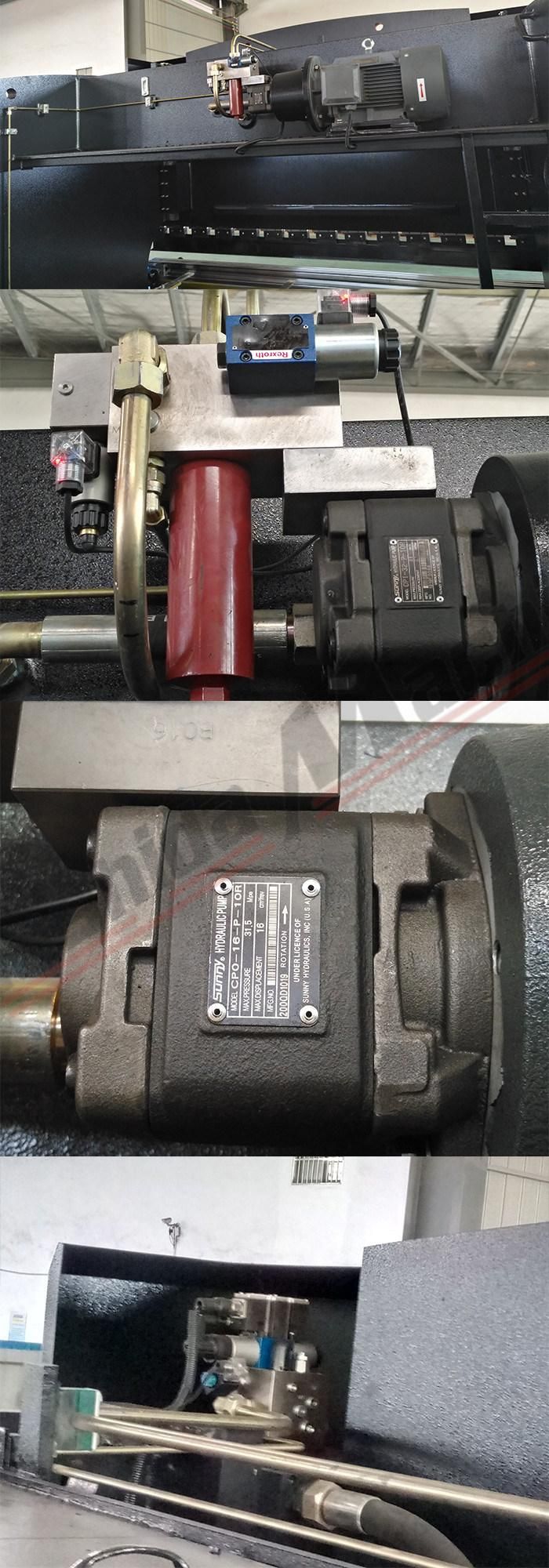

- Valve:Rexroth

- Sealing Element:Japan Nok

- Electric:Schneider

- Size:3200X1600X2600mm

- Weight:6800kg

- Voltage:380V 50Hz 30pH Can Be Customized

- Factory:Yes

- Transport Package:as Your Require

- Specification:MB8-100T*3200

- Trademark:Jiashida Machine

- Origin:Maanshan, Anhui Province, China

- HS Code:8462219000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. MB8 100T3200 Certification ISO 9001:2000, CE, TUV Automation Automatic Suitable for Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel Type Press Brake CNC System Delem Da56s Backgauge Servo Motor, Ball Screw and Linear Guide Main Motor Siemens Valve Rexroth Sealing Element Japan Nok Electric Schneider Size 3200X1600X2600mm Weight 6800kg Voltage 380V 50Hz 30pH Can Be Customized Factory Yes Transport Package as Your Require Specification MB8-100T*3200 Trademark Jiashida Machine Origin Maanshan, Anhui Province, China HS Code 8462219000 Production Capacity 100 Sets/MonthProduct Description

Delem Da56s 100t CNC Press Brake 3.2m Length Bending Machine

| DA56S CNC Press Brake Machine Features: |

| 1.Brand-new industry design combined with modern aesthetic concept, high-quality production technology, simple appearance. |

| 2.Latest high-frequency responding hydraulic control technology, faster, more efficient and accurate. |

| 3.Heat treatment of the rack, rigidity optimization verification on entire machine and the application of hydraulic compensation structure jointly ensure the bending precision of MB8 series PRESS BRAKES. |

| 4.Optimal ratio of parameters and top-level core configuration ensure stable performance and easy operation. |

| 5.MB8 standard 2 shafts back gauge system, as to complex shape work pieces, 4 or 5 shafts back gauge system and corresponding dies are available for your option. |

| 6.Press brake using fully closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to CNC system by bilateral gratings, then CNC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider Y1, Y2 running on the same frequency, maintaining the parallel state of the worktable. |

| 7.According to state of sheet metal on the press brake, CNC system can automatically control the table deflection compensation yielding uniform length of all workpieces angles. |

| 8.The use of hydraulic deflection compensation gives access to uniform full length workpieces. Hydraulic deflection compensation consists of a set of oil cylinders under the worktable, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative positions with slider keep unchanged. Compensation valves are subject to plate thickness and properties of material to be bent. |

| Machine on the Top |

| German BAUSER and Rusak+Shamban Sealing Ring |

| EMB Oil Tube Connector |

| Siemens Motor |

| German Bosch-Rexroth Valve |

| America Sunny Oil Pump |

| Schneider Electrics |

| Stable performance, long life service |

| South Kacon Foot Pedal Switch |

| Emergency buttom |

| Two black small hand shank to control the finger block to move left and right |

| Foot press up and down |

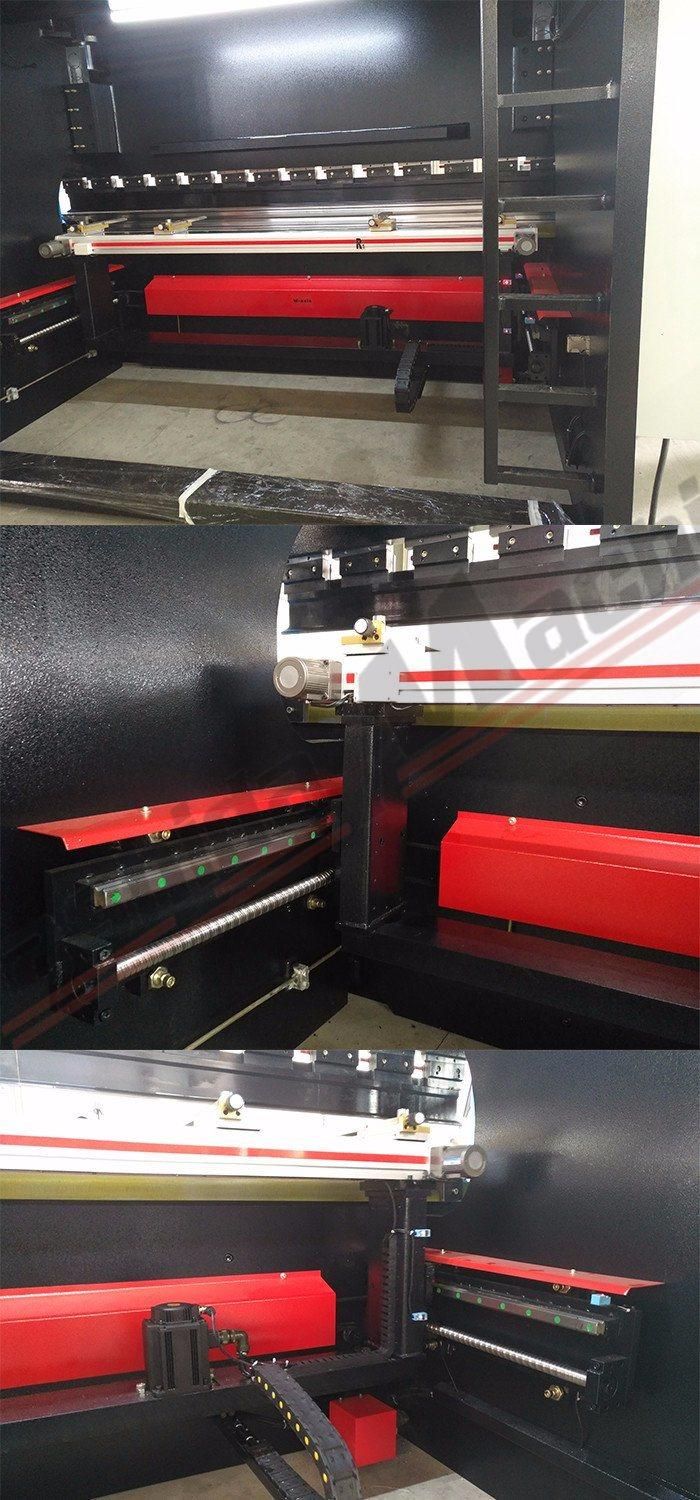

| Backgauge |

| With X and R axis |

| Taiwan Hiwin Ball Scress and Linear Guide to main the high precision |

| Estun Servo Motor controls backguage |

| Two Finger Blocks move along the beam electronically |

| Hydraulic V Crowning |

| Guarantee the straightness of metal sheet bending(can also be mechancal crowning) |

| Holland DELEM DA56S CNC Control System |

| The CNC program is generated with a one touch key stroke. You are ready to make the first part since all axes positions are automatically computed and the bend sequence has already been simulated on the screen with the machine and tools in real scale. |

| In the production mode of the DA-56 the operator can graphically simulate the bend process of the product guiding him during the press brake operation. |

| The basic machine control functions are Y1-Y2 and X axis, optionally a second back gauge axis can be used as R/Z or X2 axis. Also the crowning function is standard on board. Features |

| USB memory interface, RS-232 joint, internet (100Mb / 10Mb ) interface, power-off memory, integrated valve amplifier |

| Quick Clamp |

| Chinese quick clamping(can also be Amanda), fast tool chaning |

| Punch and Die |

| Multi-V dies Can be customized |

MORE MACHINE DETAILS, PLEASE SEND US YOUR INQIURY, THANKS.