CNC Hydraulic Press Brake Machine, Steel Plate Bending and Folding Machine, CNC Press Brake

Shaanxi HAVEN Equipment Co., Ltd.- Waterproof Rating:IPX-1

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2000, CE

- Automation:Automatic

- Suitable for:Rubber, Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:WE67K-600X8000

- Type:Press Brake

- CNC Type:Tander Prss

- Working force:6000kn

- Length of table:8000mm

- distance between frames:6000mm

- Transport Package:Steel Pallet

- Specification:Total 600t, 8000mm

- Trademark:HAVEN

- Origin:China

- HS Code:8459

- Production Capacity:30 Units,Month

Description

Basic Info.

Model NO. WE67K-600X8000 Type Press Brake CNC Type Tander Prss Working force 6000kn Length of table 8000mm distance between frames 6000mm Transport Package Steel Pallet Specification Total 600t, 8000mm Trademark HAVEN Origin China HS Code 8459 Production Capacity 30 Units/MonthProduct Description

Standard Facilities:

1. ESTUN E21 NC control + Frequency inverter

2.Front support arms

3. Motorized stroke adjustment

4. T slot on both front side and back side of the worktable

5. OMAGE Hydraulic valve

6. SUNNY hydraulic pump

7. Siemens famous brand motor

8. Siemens or Schneider Electric parts

9. Machine power is turn-off when the electric cabinet door opened

10. Upper clamps with Anti Wedges

11. Hydraulic and Electrical overload protection

12. Side safety guard and Full height back safety guard

13. With standard Top punch and Bottom Die

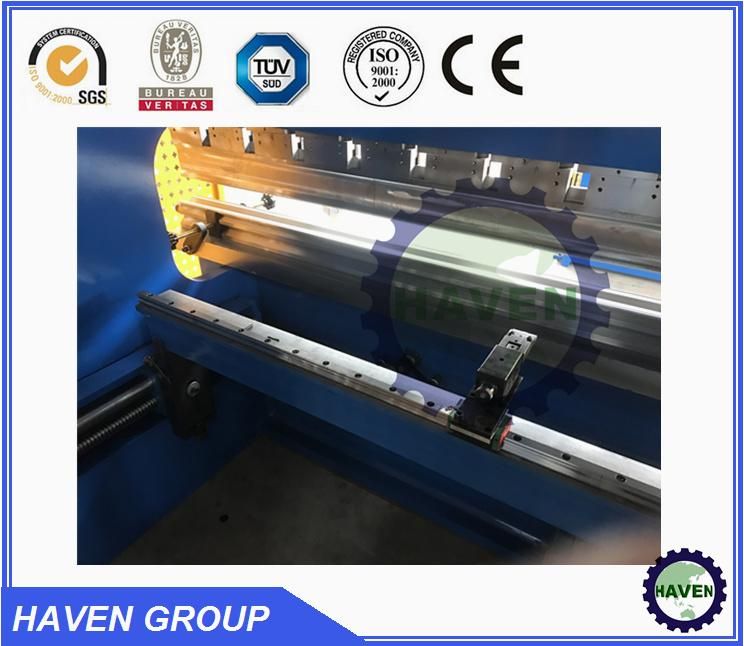

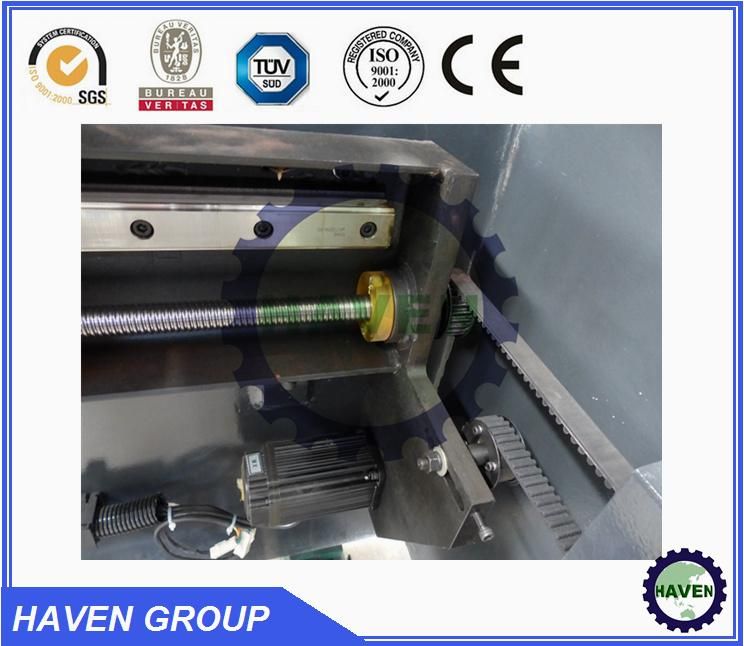

14. Back gauge beam is made of profile steel and liner guide

15. Back gauge is supported with ball screw and polished steel round bar with 0,05mm accuracy

2. Estun E21 NC Press Brake Control system:

1. Monochrome LCD Box Panel.

2. Integral factor programmable freely

3. Automatic positioning control

5.Internal time relay

6.Ram stroke counter

3. Our Services

1: Response in time after getting customer's claim

1: Provide solution in 1 day

2: Usually solve problem within 2 days

2. For big machine, Installation Service is available as per customer's requirement

4. Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments.

6. Main features

1. The whole machine is in sheet plate welded structure, which internal stress eliminated by vibration aging technology, high strength and good rigidity of machine.

2. Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, stable and reliable operation, as well as high precision.

3. Electrical adjustment and manual fine-tuning adjustment mode are adopted for distance of rear stopper and stroke of gliding block, and fitted with digital display device, easy and quick in use.

4. Upper clamp is fitted with compensation device.

5. Worktable mechanical compensation or hydraulic compensation device is optional.

| Type | Hydraulic CNC electro-hydraulic synchro |

| Working force | 6000KN |

| Length of table | 8000 mm |

| distance between frames | 6000 mm |

| Throat depth | 600 mm |

| Open height | 800 mm |

| Stroke | 320mm |

| Strokes | 2.5 /min-1 |

| Main motor | 45kw |

| CNC system | Type: DELEM DA65W Delem Co., Netherlands 3 Axis(Y1,Y2,X) +Automatic compensation |

| Tool | With 1 punching and 1 bottom die |

| Main Electric Elements in cabinet | Schneider |

| Seal in the cylinders | NOK, Japan |

| Net weight | 78000 kg |

| Overall sizes(mm) LxWxH | 8100x3480x6300 |

| Packing: | With plastic cover The machine should be disassemble during transportation. Our engineer should go to customer to assemble and adjust it. Transportation: |