High Quality Hydraulic CNC Tube Pipe Bending Machine 3D Full Automatic Pipe Tube Bender (GM-SB-89CNC-2A-1S)

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

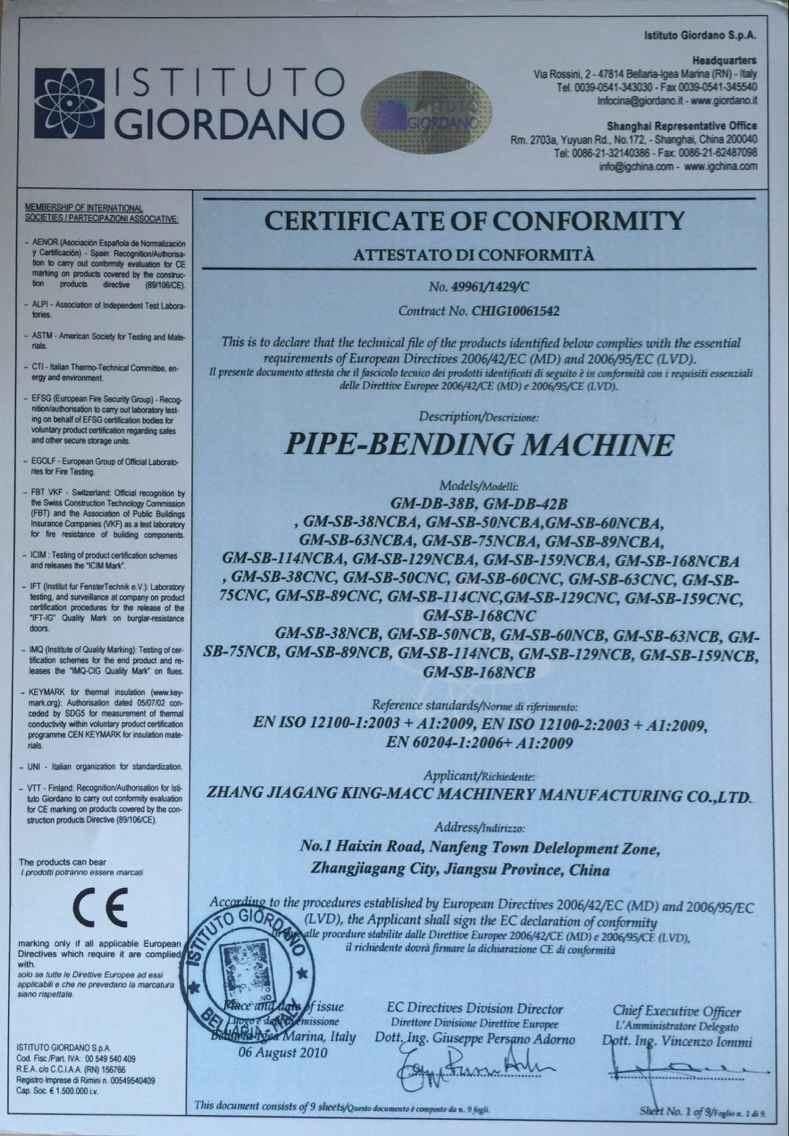

- Certification:ISO 9001:2000, CE, UL

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:GM-89CNC-2A-1S

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S., M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. GM-89CNC-2A-1S Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S., M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000 Production Capacity 5000PCS/YearProduct Description

Technical Parameter and Configuration for AutomaticPipe Bending Machine GM-SB-89CNC

Model:89CNC×2A×1S

Machine Characteristics

GM-SB-89CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinates of motions under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending spring back compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Pipe rotating (B axis), and pipe feeding(Y axis) are both driven by servo motor. Pipe bending(C axis) is hydraulic.

Main Technical Parameter

| Name | Unit | Parameter |

| Max. Bending Capacity | mm | ¢100*6 |

| Bending Radius Range | mm | 40-400 |

| Max. Bending Angle | ° | 190° |

| Bending Speed | °/sec | 25 |

| Turning Speed | °/sec | 160 |

| Feeding Speed | mm/sec | 500 |

| Bending Precision | ° | ±0.10 |

| Turning Precision | ° | ±0.10 |

| Feeding Precision | mm | ±0.10 |

| Turning Servomotor Power | kW | 1.5 |

| Feeding Servomotor Power | kW | 1.5 |

| Max feeding length | mm | 4000 |

| System Motor Power | kW | 11 |

| Max. Pressure | Mpa | 16 |

| Oil Pump Delivery Volume | L | 30 |

| L*W*H (Packaging Dimension) | mm | 5000*1350*1200 |

| Weight | T | 4.8 |

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens( Beide)or Runmali |

| Hydraulic Pump | Wuxi Tuoli |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Suzhou Boguan |

| Cylinder | Shanghai Qifan |

| Oil tube | Suzhou Kejia |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Servo Motor | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Switch power | Wenzhou Changxing |

| Contactor | German SCHNEIDER(Imported) |

| Other Electric Parts | German SCHNEIDER,Omron, Taiwan SHILIN(Imported) |

contact person:Ms Georgina Huang

Mob:008613606222268