Shear Line Automatic Galvanized Metal Steel Sheet Coil Cut to Length Line Machine

Cangzhou Nexus Machinery Co., Ltd.- After-sales Service:Provide Overseas Service

- Automation:Semi-automatic

- Certification:CE, ISO 9001:2000

- Condition:New

- Warranty:1 Year

- Motor Power:3kw

Base Info

- Model NO.:NM108

- Hydraulic Power:3 Kw

- Work Speed:10-12m,Min

- No. of Leveling Groups:7 Groups

- PLC Brand:Panasonic,Siemens,Delta

- Encode:Omron

- Weight of Machine:3.5 Tons

- Package:Wooden Box Package

- Transport Package:Wooden Package

- Specification:2.6*1.6*1.2m(L*W*H)

- Trademark:NEXUS MACHINERY

- Origin:Cangzhou, China

- HS Code:8462312000

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. NM108 Hydraulic Power 3 Kw Work Speed 10-12m/Min No. of Leveling Groups 7 Groups PLC Brand Panasonic,Siemens,Delta Encode Omron Weight of Machine 3.5 Tons Package Wooden Box Package Transport Package Wooden Package Specification 2.6*1.6*1.2m(L*W*H) Trademark NEXUS MACHINERY Origin Cangzhou, China HS Code 8462312000 Production Capacity 50 Sets/MonthProduct Description

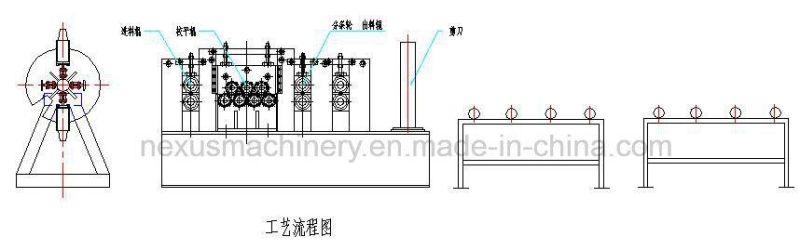

Shear Line Automatic Galvanized Metal Steel Sheet Coil Cut To Length Line MachineShear Line Automatic Galvanized Metal Steel Sheet Coil Cut To Length Line Machine is mainly used to cut metal plate for required length acccording to user. It is automatic cut length while set required length datas on Plc system. For this machine, we design it to suit 5 groups different length data, while one group product is finished, the cut to length machine will start to produce the next group product automatically. It is very simple and safe for machine operator. The Cut to lenght machine Line includes manual decoiler, cut to length machine and output table.

1. Main Technical Details:

5 tons Manual decoiler

- Expanding Range: Φ480~Φ520mm

- Capacity:5 Ton

- Max width for coil: 1250mm

- Material of shaft: Gcr45 steel

- Size of winder: About (H*L*W)1 M*1.9M*0.5M

- Weight of equipment: About 200kgs

- Raw material width: 1500mm

- Thickness of raw material: 0.2-1.0mm

- Working speed:10-12m/min

- Transmission: Three group rubber rollers

- Diameter of rubber roller:110mm

- Leveling system: 7 groups rollers(3 group in upper,4 group in below)

- Material of leveling rollers: Gcr15 bearing steel, quenched 55-58

- Main power: 3kw

- Hydraulic cutting: 3kw

- Electrical control system: PLC Panasonic Japan. 380V, 50HZ,3 phases( Also Can Customize)

| No. | Product Name | QTY |

| 1 | Shear Line Automatic Galvanized Metal Steel Sheet Coil Cut To Length Line Machine | 1 |

3. Character of main structure:

- The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

- All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

- It is very easy to install the equipment and suitable for producing in the factory.

- Low noise with high efficiency.

More Products for your Choose:

ABOUT US:

Cangzhou Nexus Machinery Co.,Ltd is experienced manufacturer & exporter of cold roll forming machine with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, so we are able to assist customers with professional designing and solution.

Our range of products: roof tile roll forming machine, cladding roll forming machine, metal decking roll forming machines, C/U/Z/W/L steel purlin roll forming machine etc. We also can supply steel coils, roof panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Azerbaijan and Kazakhstan.

We have rich experience for cold roll forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.