Wc67K Hydraulic Press Brake with Nc E21 Controller for Sheet Metal Bending, Metal Box Bending Junction Box Bending with Goose Neck Mould

Anhui LIFU Machinery Technology Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

- Certification:ISO 9001:2000, ISO 9001:2008, CE

- Automation:Automatic

- Suitable for:Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:WC67K

- Type:Press Brake

- Motor:Siemens Beide

- Function:Metal Bending

- Material:Aluminum, Ss, Ms, etc

- Color:Optional

- Hydraulic Valve:Rexroth

- Electrics:Schneider Electrics

- Transport Package:Plastic Film, Wooden Package, or as Requirement.

- Trademark:Durmark

- Origin:China Anhui

- HS Code:8462919000

- Production Capacity:60

Description

V-working:9

V-return: 45

V-unload: 50

Main feature

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

4. Torsion axis synchronization for slide synchronous mechanism.

5. Adopt a mechanical stopper mechanism, stable and reliable.

6. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

7. The CNC system adopts frequency conversion control technology, with multi-step

programming function, simple and easy to operate.

8. Inclined wedge deflection on the compensation mechanism, in order to guarantee access to high bending accuracy

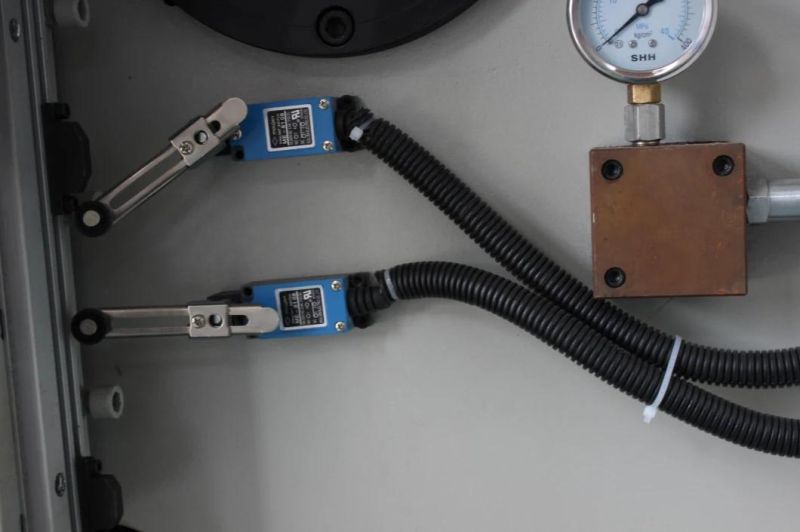

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

Detailed Photos

Our service

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 2 years

4. Engineers available to service machinery oversea

Workshop

Customer

Package

FAQ

Q1: How can I get the after-service?

A: We provide two years warranty and lifelong maintenance.

We will send you the spare parts freely if the problems caused by us.

Any problem, you can call us directly.

Q2: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Our factory address: Bowang industry park,Maanshan City,China

Our factory is near Nanjing Lukou Airport.We can pick you up in the airport.

Hotel booking service is available .

Q3:Are you a factory or trade company?

A: We are manufacturer with own factory for 9 year, export proportion 50~60%.

Q4:How can I trust your company?

A:With 9-years-professional design, we can provide you suitable suggestion and lowest price

1. Assessed by third party, CE, ISO for all equipment, .

2. Welcome to inspect anytime. We are near to Nanjing Lukou Airport.

3. For our machine, we do very well on hydraulic press brake, shearing machine, power press , hydraulic press and other metal processing machines.

Q5 :Is your price competitive?

A: Only good quality machine we supply. Surely we will give you best factory price based on superior product and service.

Contact