CNC Hydraulic Metal Press Brake, Plate Bending Machine Wc67K-100t3200

Anhui ZhongDe Machine Tool Co., Ltd.- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2008, CE

- Automation:Automatic

- Suitable for:Aluminum, Alloy, Carbon Steel, Stainless Steel

- Type:Press Brake

Base Info

- Model NO.:WE67K-100T3200

- Model:We67K-100,3200

- Max Bending Length:3200mm

- Transport Package:Steel Fixed

- Specification:WE67K-100,3200

- Trademark:ZDMT

- Origin:China

Description

Basic Info.

Model NO. WE67K-100T3200 Model We67K-100/3200 Max Bending Length 3200mm Transport Package Steel Fixed Specification WE67K-100/3200 Trademark ZDMT Origin ChinaProduct Description

CNC Plate Bending Machine 100Ton 3200mm

Main functions and features

· Electric hydraulic proportinal servo synchronization, ensuring repeated accuracy.

· Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02.

· Lower worktable has compensation device to anti deflection & upper tool has wedge compensation device.

· Holand Delem CNC control system, linear scale, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance.

· Ram strok(Y1, Y2),backgague (X, R, Z) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision.

· Multi-axis controlling allows this type of press brake to be designed and manufactured into a soft fabrication centre.

Related configuration with details

· Rear view of Synchro CNC press brake ZDPE-10032

· Brand new integrated backgauge system with extra thick beam for high parallelism, rigidity and durability

· Totally sealed design of X axis transmission for protecting inside ball screw and linear rail and achieving high precison and reducing maintenance

· Servo motor and steel wire belt are used for high controlling accuracy, positioning precision and lower noise.

· 3 hydraulic cylinder are used for crowning system to reduce angle deflection on middle of plate

· Schneider electrics are adopted for reliability and longer lifespan

· Highly-precise CNC tooling and quick clamping are used for extra precision, durability and fast tool changing.

· Imported brand grating scale for no delay feedback of Y axis data and sensative transducing

· Imported brand hydraulics, stable, resistant to high tempareture and high pressure, persistent on fine working accuracy

· Double sliding front support arm, horizontally movable for easy shift between single person or two persons working standing postion.

· Vertically adjustable finger stopper sliding on beam of double liner guide rail. Vertical manual adjustment for apply on different tools

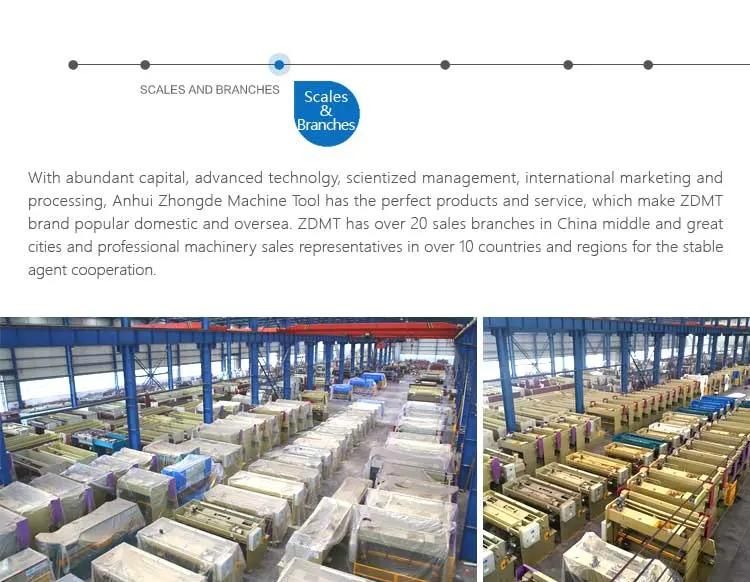

Company Informations: