China Supplier Stainless Steel Pipe and Tube Bender (GM-SB-38CNC)

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

- Certification:ISO 9001:2000, CE, UL

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:GM-SB-38CNC

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S, M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Bending Drive:Hydraulic

- Technical:Cold Bend

- Company:Sino-Italian Joint Venture

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. GM-SB-38CNC Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S, M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Bending Drive Hydraulic Technical Cold Bend Company Sino-Italian Joint Venture Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000 Production Capacity 5000PCS/YearProduct Description

1. Compeltely Automatic2. PLC, Servo Motor: Mitsubishi/Delta/Omron

3. Touch Screen: Mitsubishi/Delta/Weinview

3. Hydraulic valve: Japan Yuken

4. Hydraulic pump: Japan Yuken

5. High Efficiency/Stability

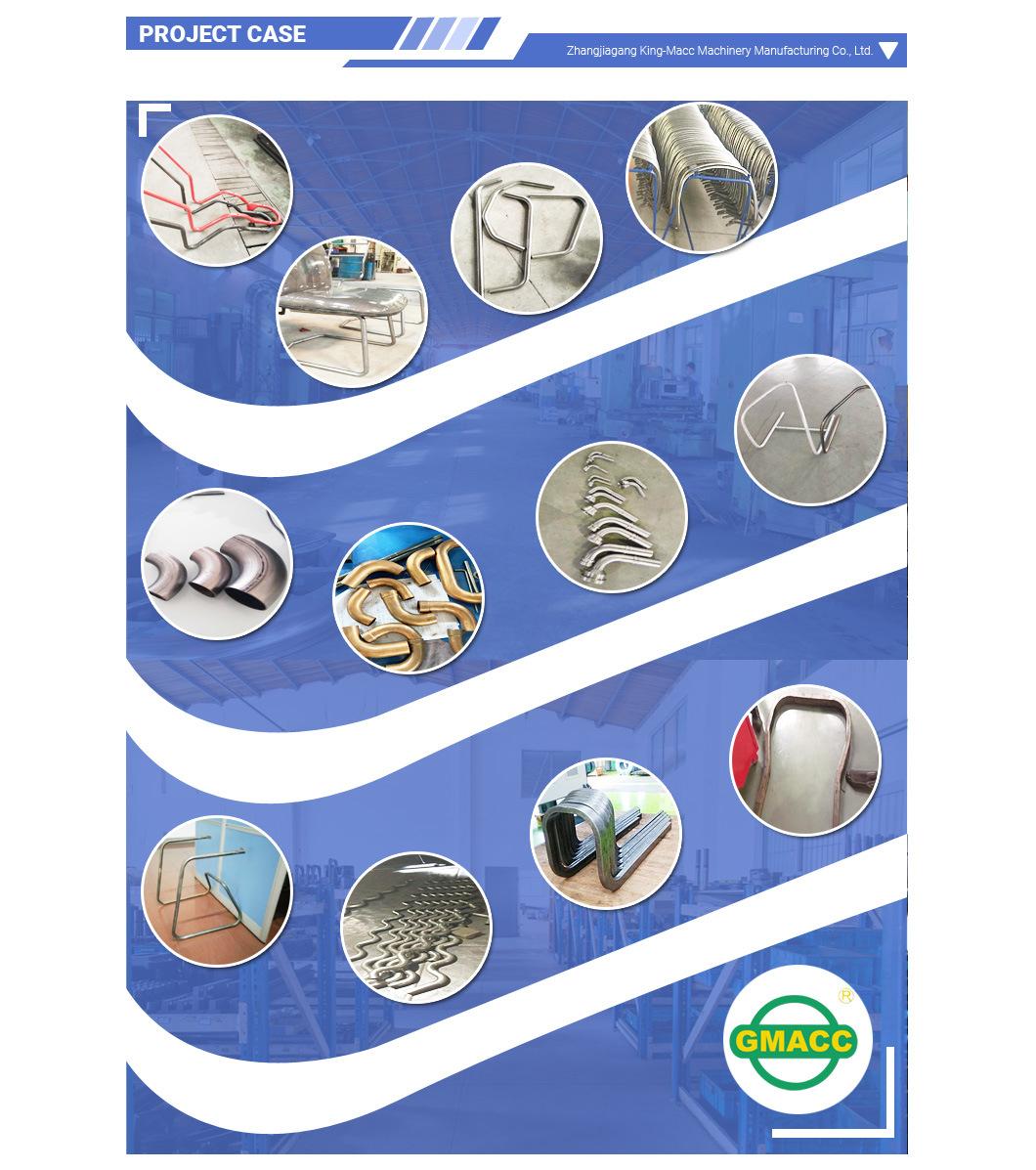

6. Application Field: Automobile, Motorcycle, Air-Conditioner, Furniture, Boiler,

The series was adapted in particular to professional world market requirements. All the parts, structure and characters are similar to the standard of mechanical engineering from Europe. Our professional experience and drawings plans for Electric, Electronic, Hydraulic and mechanical from known companies bring to upgrading of the machines' systems to accurate and attractive performance.

SB-CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinatesofmotion under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending springback compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Advanced technology, high automation reliability, integrated design all make CNC pipe bending machine the first class pipe processing machine in the world.

Features:

1. Applicable tube material: Carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2. Applicable tube shape: Round, solid bar, square, rectangle, oval, profile etc.

3. Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4. Y, B, C three coordinates of motion under precision control by PLC realizing full-auto mandrel on or mandrel off rapid bending.

5. Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision plus/minus 0.1 degree.

6. About 2000 programs can be input into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7. Various Touch screen language are available for choice as per request.

8. Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9. Guiding Die has auxiliary pushing function and at the same time it possesses Reiteration and entering repeat functions that can make the guiding module length shorten.

10. Counter function can accurately count work piece's quantity and save data whether in power-on or power-off situation.

11. Moveable foot switch with function of auto-start, pause and emergent-stop.

12 Optional function of slow bending.

13. Optional function of anticipated mandrel extraction.

| Name | Unit | Parameter |

| Max. Bending Capacity | mm | O.D38*2 |

| Bending Radius Range | mm | 20-200 |

| Max. Bending Angle | ° | 190° |

| Bending Speed | °/sec | 60 |

| Turning Speed | °/sec | 200 |

| Feeding Speed | mm/sec | 1000 |

| Bending Precision | ° | ±0.10 |

| Turning Precision | ° | ±0.10 |

| Feeding Precision | mm | ±0.10 |

| Turning Servomotor Power | kW | 0.4 |

| Feeding Servomotor Power | kW | 1 |

| Though Effective Distance | mm | 2000 |

| System Motor Power | kW | 4 |

| Max. Pressure | Kg/cm | 14 |

| Oil Pump Delivery Volume | L | 16 |

| L*W*H (Packaging Dimension) | mm | 3500*700*1300 |

| Weight | T | 2.0 |