Reliable/High Service Performance Hydraulic Amanda Press Brake Machine

Maanshan Middle Asia Machine Tools Manufacture Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2008, CE

- Automation:Automatic

- Suitable for:Aluminum, Carbon Steel, Stainless Steel

Base Info

- Type:Hydraulic Bending Machine

- Raw Material:Steel Bar

- Key Selling Points:Competitive Price

- Usage:Rail Bending Machine

- Motor Power (Kw):5.5 Kw

- After-Sales Service Provided:Online Support

- Extra Services:End Forming

- Weight (Kg):4000

- Width of Working Table (mm):1300 mm

- Nominal Pressure (Kn):630 Kn

- Power:Hydraulic

- Color:Customized

- Slider Stroke (mm):100 mm

- Machine Type:Synchronized

- Throat Depth (mm):250 mm

- Length of Working Table (mm):2500 mm

- Transport Package:Plastic Cover

- Specification:CE STANDARD

- Trademark:ZYMT

- Origin:Anhui, China

- Production Capacity:100 Set,Sets Per Month Reliable,High Service Per

Description

Basic Info.

Type Hydraulic Bending Machine Raw Material Steel Bar Key Selling Points Competitive Price Usage Rail Bending Machine Motor Power (Kw) 5.5 Kw After-Sales Service Provided Online Support Extra Services End Forming Weight (Kg) 4000 Width of Working Table (mm) 1300 mm Nominal Pressure (Kn) 630 Kn Power Hydraulic Color Customized Slider Stroke (mm) 100 mm Machine Type Synchronized Throat Depth (mm) 250 mm Length of Working Table (mm) 2500 mm Transport Package Plastic Cover Specification CE STANDARD Trademark ZYMT Origin Anhui, China Production Capacity 100 Set/Sets Per Month Reliable/High Service PerProduct Description

Reliable/High Service Performance Hydraulic Amanda Press Brake Machine

Product Introduction

Product Introduction

Main introduction

The NC Wc67 Hydraulic Press Brake (NC bending machine) is structured in steel plate fabrication with sufficient strength and rigidity. The hydraulic drive prevents the machine from serious overload operation accidents caused by the change of sheet thickness or bad choice of lower die cavity. Additionally, this machine is also featured by the steadiness of work, convenience of operation, and reliable safety. The connecting section to the upper die is provided with compensation device, which compensates the deflection of worktable and ram in bending and guarantees the high work precision. Meanwhile, the mechanic block is equipped in the oil cylinder to ensure the fixing accuracy when the ram travels to the bottom dead point and so as to assure the consistency of bending angle in bulking production. The back gauge is mechanic transferring drive by motor. Both of ram travel and back gauge position is positioned by NC controller through the encoders. It is widely used in plane, automobile, shipbuilding, and machine with high production efficiency.

Controllers

·60x×160 LCD display ·Backnauoe and block control

·Control for general AC motors,frequency inverter

·Intellgent positioning ·Stock counter

·Holding/decompression time setting

·Program memory of up to 40 programs, up to 25 steps steps per program

·One side positioning-

·Retract function ·One key backup/restore of parameters.

·mm/inch ·Chinese/English

Sandard Equipments

Sandard Equipments

·Main Motor: Famous Brand China

·Hydraulic valves: Germany Famous Brand

·Pump: Famous Brand China/USA

·Main electrics: Famous Brand

·Babb screw: Famous Brand

·Seal ring: DZ Taiwan/NOK Japan

·Foot Switch: Famous Brand South Korea

·Manual adjustable front support

Sandard Equipments

·Hydraulic valves: Germany BOSCH/ HOERBIGER

·Servo drive and motors: Nanjing ESTUN

·Grating ruler: Germany HEIDENHAIN/ Italy GIVI/Spain FAGOR

·Ball screw and linear guide: Taiwan HIWIN

·Main electrics France SCHNEIDER

·Hydraulic crowing table(under<500T)/mechanical crowing table(up to ≥500T)

·Manual adjustable front support with linear

Main features

1.Whole steel welded structure, with internal stress eliminated by vibration aging technology, high strength and good rigidity.

2.Integrated hydraulic system, with Bosch Rexroth brand valves, upper transmission, pressure control for adjustment of tonnage.

3.Moveable foot-pedal switch with emergency stop button.

4.Segmented upper punch, adopt oblique steel solid deflection compensation device, and multi-V die in one piece.

5.Ram and back gauge with programmable positioning NC controller.

6.International standard Schneider brand electrics and switches, main motor use Siemens Brand.

7.Various brands of NC controllers for options: Estun E21/E200, Elgo P40, Delem DA41, Maper HT072

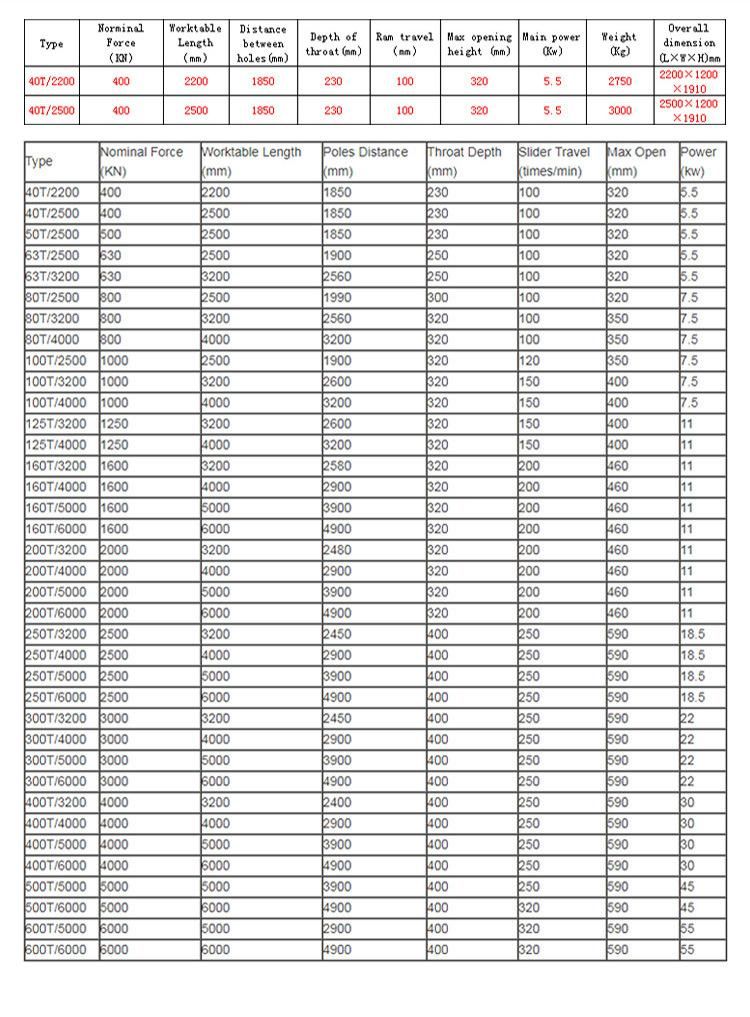

Specification Parameter

About Us

About Us

Certificate

Certificate

Packing and Transportation

Packing and Transportation

FAQ

FAQ

1, Q: Are you factory or trading company?

A: We are factory of Wc67 Hydraulic Press Brake(bending) machine ,shearing machine and fiber laser cutting factory was established in 1988, with more than 30 years producing experience.

2, Q: What's your payment?

A: T/T, 30% deposit in advance, 70% balance before ship.

Irrevocable L/C at sight

3, Q: What's about delivery time?

A: For small model Wc67 Hydraulic Press Brake, usually 15-30 days after received 30% deposit.

For big model Wc67 Hydraulic Press Brake, usually 40-120 days after received 30% deposit.

4, Q: We don't know how to use the machine, can you help us?

A: 1, We will send machine operation manual with machine;

2, If customer require, we will send technician to your factory teach you how to use it and maintain it;

3, You can send technician or workers to our factory, we will teach then how to use and maintain the machine.

5, Q: We are worry about the machine quality?

A: Our machine warranty is 2 years. Before ship the machine, we will test it about 7-10 days, when you received it,you can use it directly, no need test it again.