High Quality Fully Automatic High Speed Pipe Bending Machine Made in China

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

- Certification:ISO 9001:2000, CE, UL

- Automation:Semi-Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:GM-SB-63NCB

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S, M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Bending Drive:Hydraulic

- Technical:Cold Bend

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

Description

Basic Info.

Model NO. GM-SB-63NCB Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S, M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Bending Drive Hydraulic Technical Cold Bend Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000Product Description

High Quality Fully Automatic High Speed Pipe Bending Machine Made In ChinaMachine CharacteristicFull hydraulic drove, PLC controlled with touch screen or text pipe bending machine, equipped with devices of pipe clamping, guide mould, mandrel, crease-resistant, assist pushing, pipe bending and so on. Under hydraulic operation, this professional, high speed and economic European pipe bending machine can bend various dimension both normal and abnormal shape metal pipes and bending angles are controlled by high precision imported encoder which ensures high precision of this machine.

Main Technical Parameter

| Name | Unit | Parameter |

| Mild steel round tube | mm | 63*4 |

| Stainless Steel | mm | 63*3 |

| Light alloy annealed round tube | mm | 63*6 |

| Mild steel square tube | mm | 50*50*3 |

| Mild steel rectangular tube | mm | 50*45*3 |

| Mild steel round solid bar | mm | 30 |

| Mild steel square solid bar | mm | 25*25 |

| Min. bending radius | mm | 25 |

| Max. Bending radius(Standard) | mm | 300 |

| Head overhang (on bending centre) | mm | 760 |

| Mould centre height | mm | 60 |

| Bending centre height (from floor) | mm | 1016 |

| Max. Bending Angle | ° | 190° |

| Through Effective Distance | mm | 3500 |

| Bending Speed(Max.) | °/sec | 30 |

| Bending angle Precision | ° | ±0.10 |

| System Motor Power | KW | 5.5 |

| Hydraulic Pump Volume | L | 19 |

| Max. Pressure | Mpa | 16 |

| L*W*H (Packaging Dimension) | mm | 4500*1200*1350 |

| Machine Weight | T | About 3.0 |

Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens(Beide)or Runmali |

| Hydraulic Pump | Wuxi Tuoli |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Taiwan Shanghong (Imported) |

| Cylinder | Shanghai Qifan |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Switch power | Taiwan Mingwei |

| Contactor | Schneider |

MODEL:GM-SB-63NCB(machine photo only for your reference)

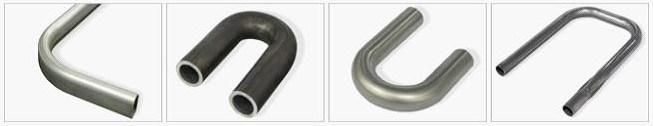

Bending Samples

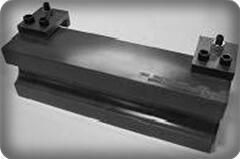

Tooling Samples Bending Die Clamp Die Pressure Die

Tooling Samples Bending Die Clamp Die Pressure Die

Mandrel Wiper Die(optional)

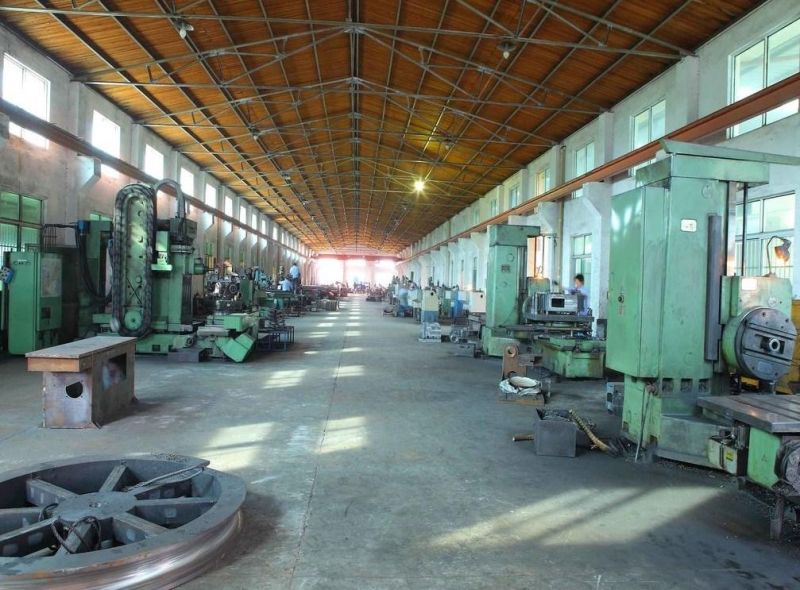

Company Photos

CNC Machining Center

CNC Machining Center