Semi Automatic Hydraulic Pipe Bender GM-Sb-129ncb

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

- Certification:ISO 9001:2000, CE, UL

- Automation:Semi-Automatic

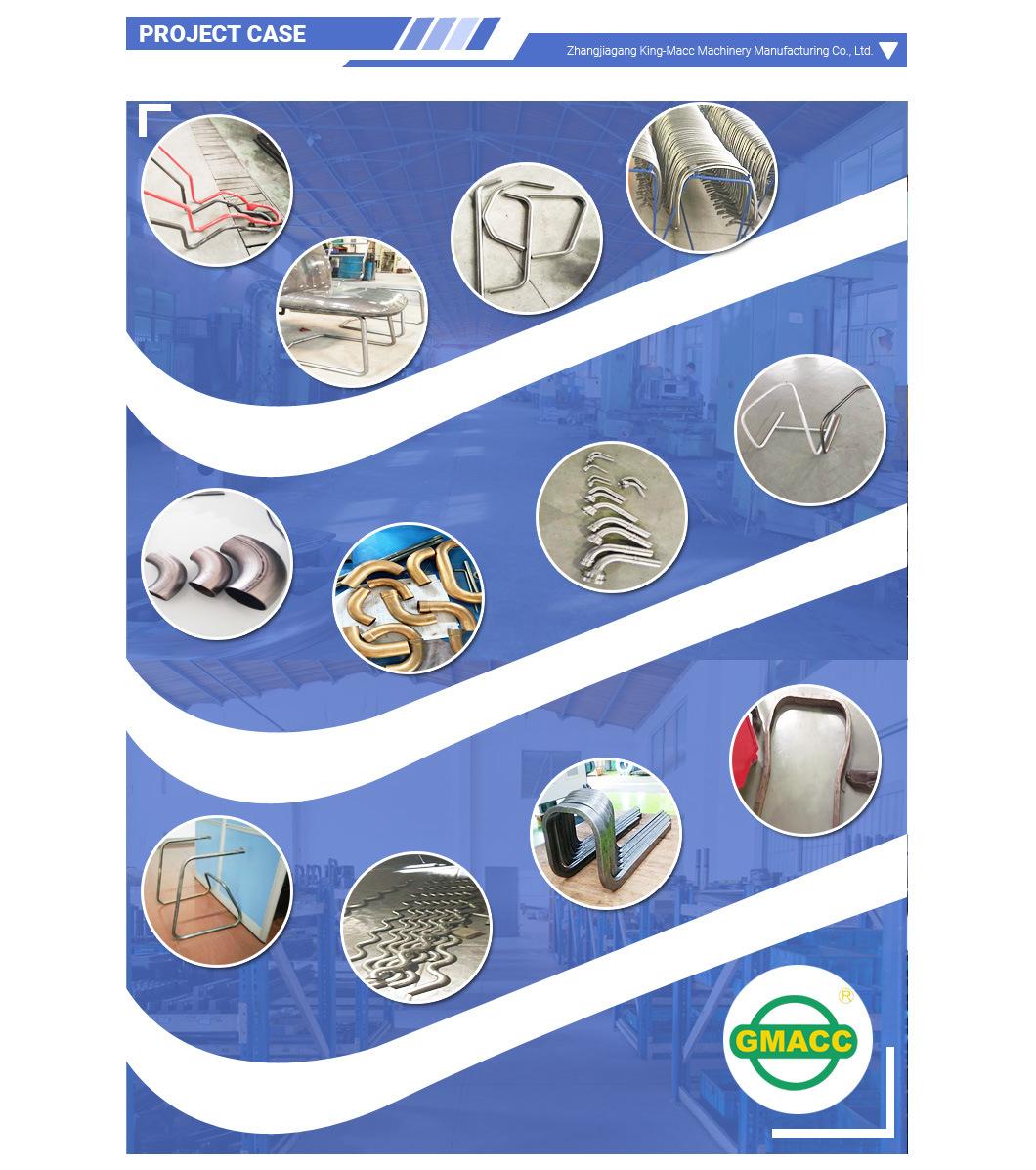

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:GM-SB-129NCB

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S, M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Bending Drive:Hydraulic

- Technical:Cold Bend

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. GM-SB-129NCB Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S, M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Bending Drive Hydraulic Technical Cold Bend Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000 Production Capacity 5000PCS/YearProduct Description

Technical Parameter and Configuration for Automatic Pipe Bending Machine GM-SB-129NCB- Machine Characteristic

- Main Technical Parameter

| Name | Unit | Parameter |

| Max. Bending Capacity | mm | ¢129*14 |

| Bending Radius Range | mm | 50-550 |

| Max. Bending Angle | ° | 190° |

| Though Effective Distance | mm | 4000 |

| Bending Speed | °/sec | 15 |

| Bending Precision | ° | ±0.10 |

| System Motor Power | KW | 18.5 |

| Oil Pump Delivery Volume | L | 45 |

| Max. Pressure | Mpa | 16 |

| L*W*H (Packaging Dimension) | mm | 5600*1350*1300 |

| Machine Weight | T | 6.8 |

- Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens( Imported)or Wuxi Taihu |

| Hydraulic Pump | Taiwan Hydromax(Imported) |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Taiwan Shanghong (Imported) |

| Cylinder | Shanghai Jingsheng |

| Oil tube | Suzhou Kejia |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Servo Motor | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Switch power | Wenzhou Changjiang |

| Contactor | German SCHNEIDER(Imported) |

| Other Electric Parts | German SCHNEIDER,Omron, Taiwan SHILIN(Imported) |