Auto Channel Letter Bender for Trim Cap Aluminum Letters

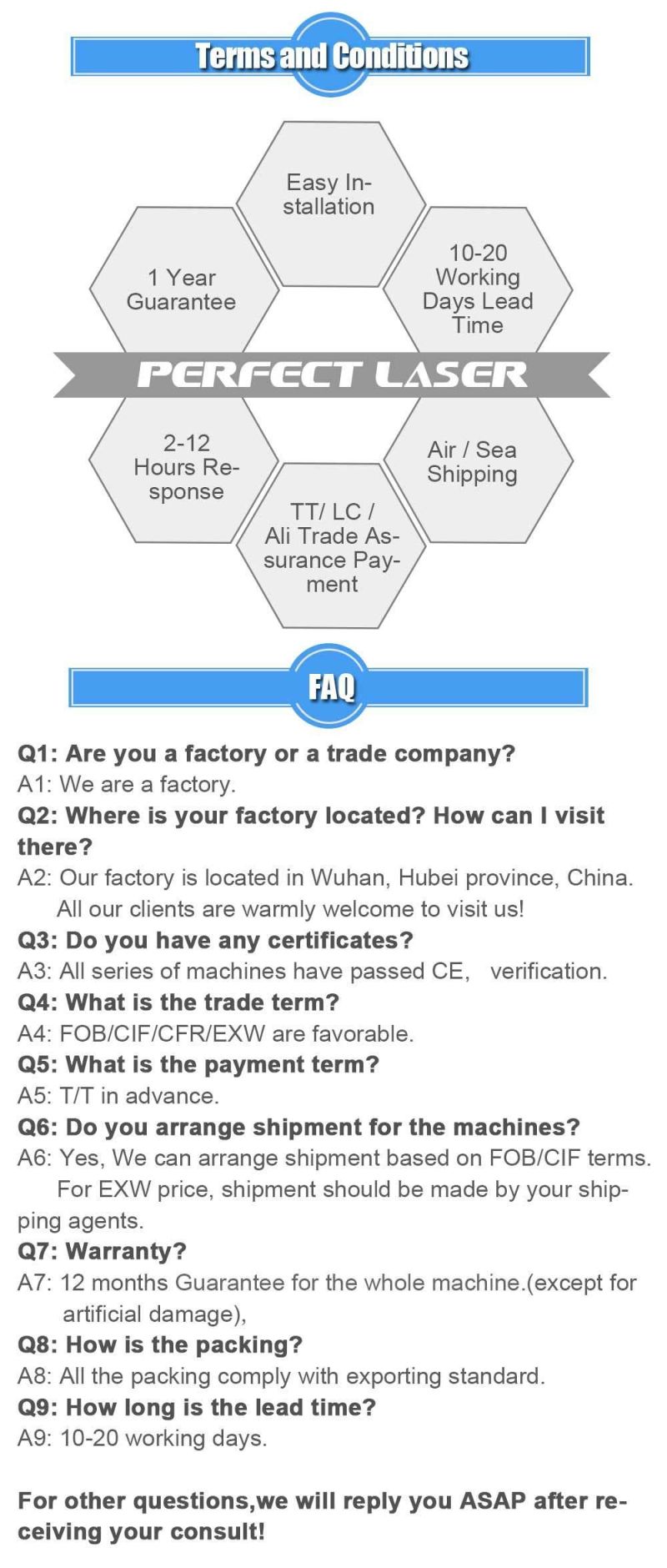

Perfect Laser (Wuhan) Co., Ltd.- After-sales Service:Lifetime After-Sales

- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2000, CE

- Automation:Automatic

Base Info

- Model NO.:PEL-800

- Suitable for:Plastic, Rubber, Copper, Alloy, Stainless Steel

- Type:Cnc Bending Machine

- Control Type:PC Control Type

- Application Material:Stainless Steel, Galvanized Sheet, Aluminum Coil

- Material Thickness:0.6-1.0mm

- Power:4.0kw

- Compressed Air:0.4-0.6MPa

- Control Axis Quantity:5axis

- Bending Distance From Start:3mm

- Min. Bending Radius:R7mm

- N.W./G.W.:800kgs,900kgs

- Dimension:2290(L)*860(W)*1560(H)mm

- Transport Package:Wooden Case

- Specification:ISO 9001, CE

- Trademark:Perfect Laser

- Origin:China

- HS Code:8548900090

- Production Capacity:1000 Units, Month

Description

Basic Info.

Model NO. PEL-800 Suitable for Plastic, Rubber, Copper, Alloy, Stainless Steel Type Cnc Bending Machine Control Type PC Control Type Application Material Stainless Steel, Galvanized Sheet, Aluminum Coil Material Thickness 0.6-1.0mm Power 4.0kw Compressed Air 0.4-0.6MPa Control Axis Quantity 5axis Bending Distance From Start 3mm Min. Bending Radius R7mm N.W./G.W. 800kgs/900kgs Dimension 2290(L)*860(W)*1560(H)mm Transport Package Wooden Case Specification ISO 9001, CE Trademark Perfect Laser Origin China HS Code 8548900090 Production Capacity 1000 Units/ MonthProduct Description

Auto Channel Letter Bender for Trim Cap Aluminum Letters

(PEL-800)

Contact: Betty

Product Description:

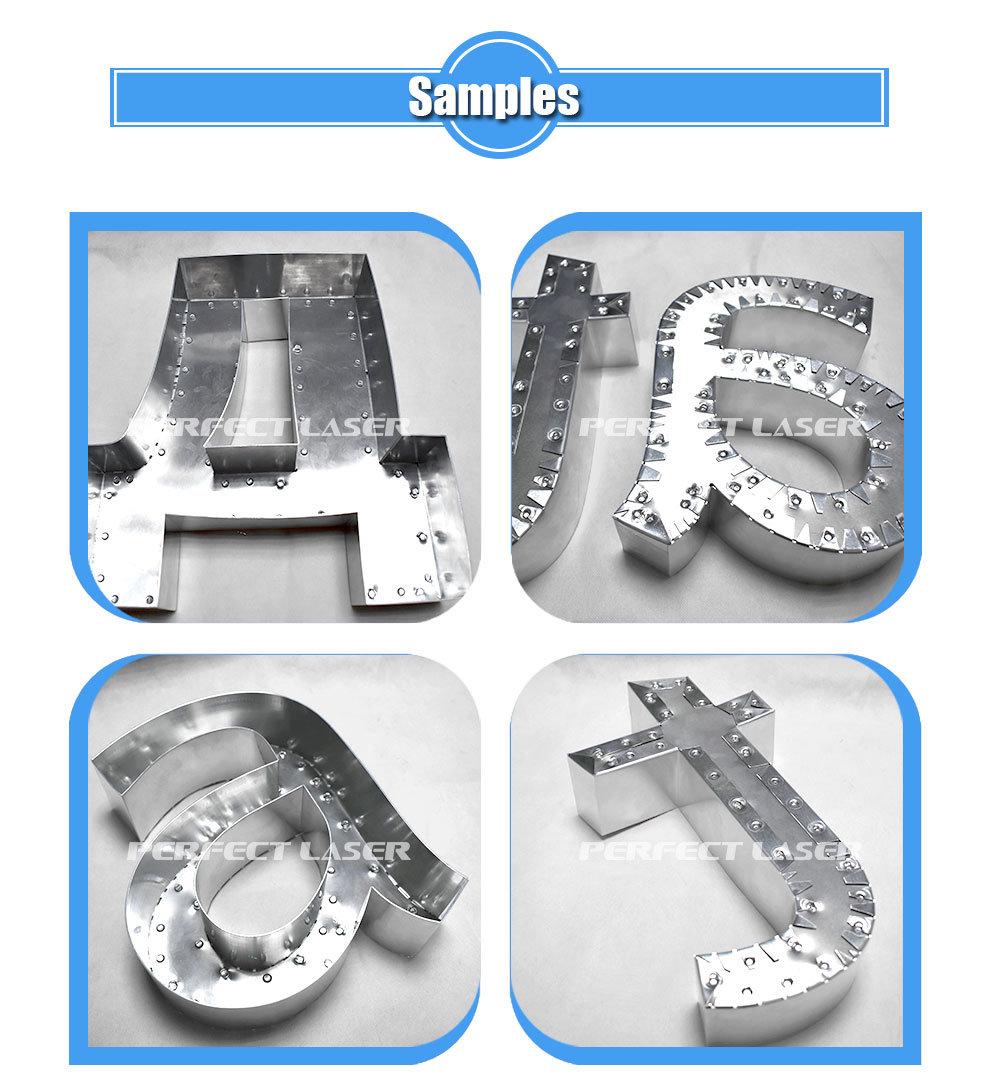

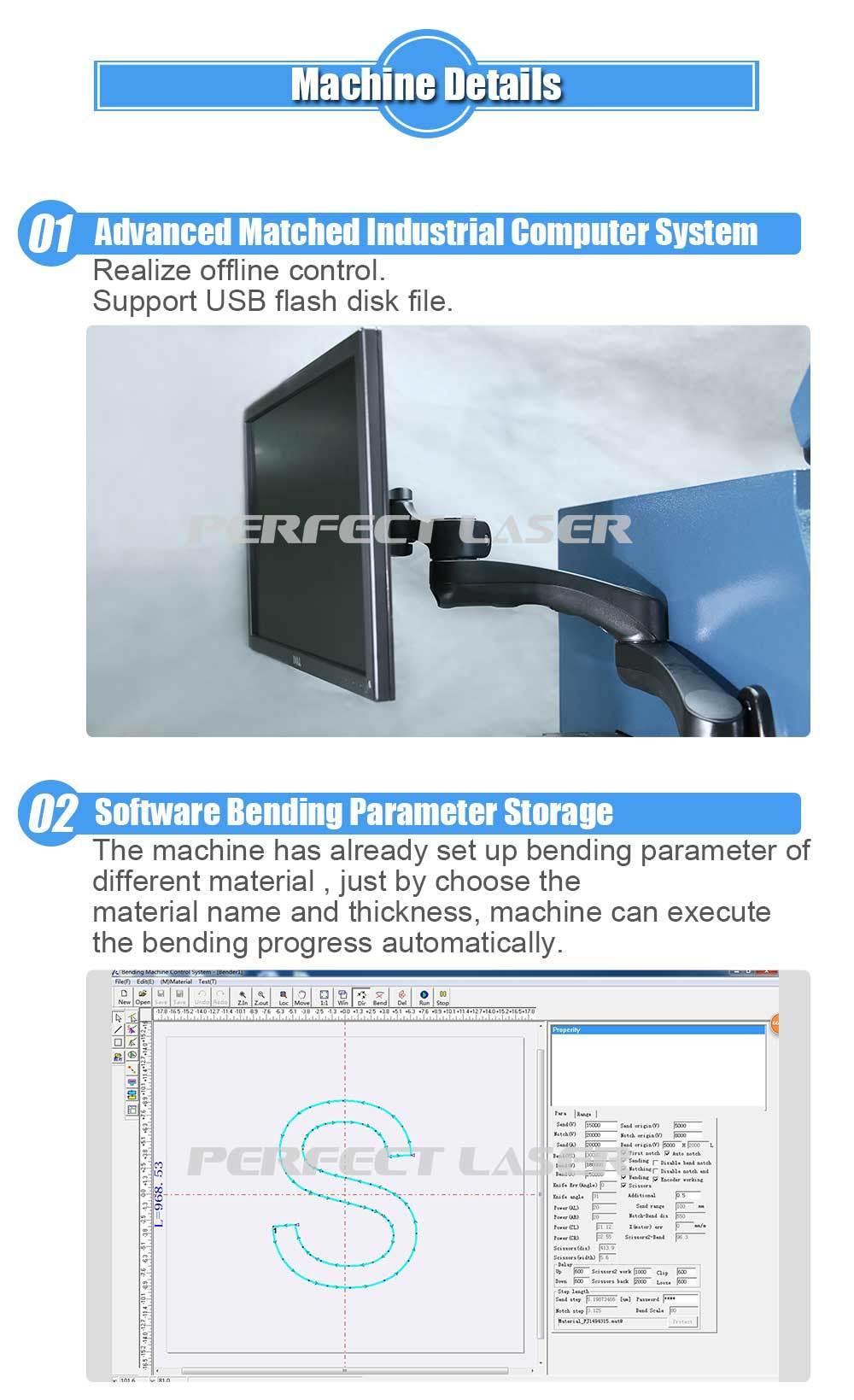

Auto Channel Trim Cap Aluminum Letters Bender Machine PEL-800 adds a set of teeth cutting bending module based on PEL-700 channel bending and flanging machines, and it uses a multi arbor bending system and quick-change system mold for precision bending. It is not only with all features of PEL-700 model, but also has a flat aluminum coil automatic gear cutting and folding function. It is the preferred high-end equipment for upscale square landscape character, stainless steel letters, punching letters, resin letters, giant luminous characters etc.

Product Features:

Technical Data:

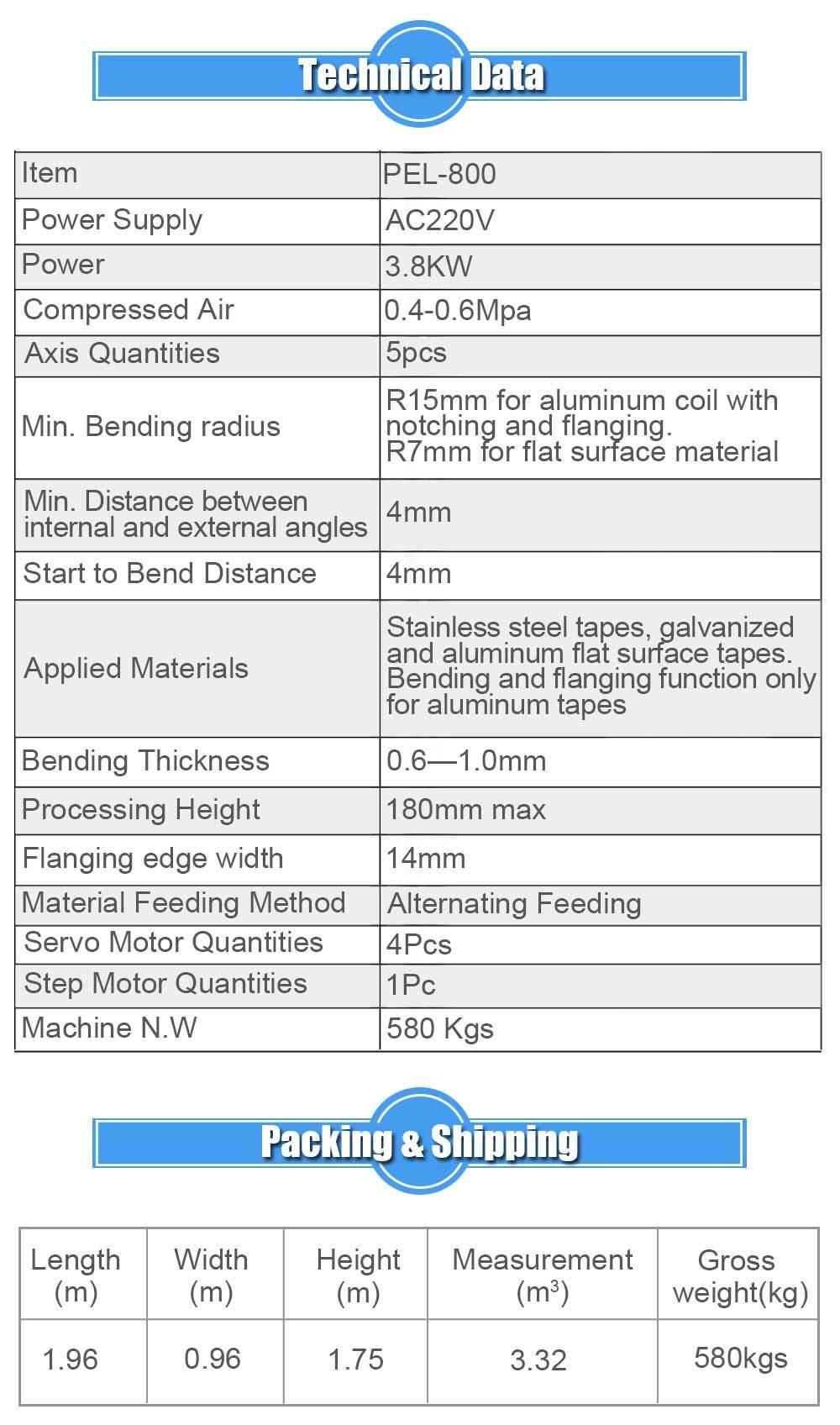

| Power supply | AC200V |

| Power | 4.0KW |

| Compressed air | 0.4-0.6MPa |

| Control axis quantity | 5axis |

| Min. Bending radius | R7mm |

| Min. Distance between interior angle and exterior angle | 4.5mm |

| Bending distance from start | 3mm |

| Applied material | Stainless steel, galvanized sheet, aluminum coil |

| Material thickness | 0.6-1.0mm |

| Processing height | Stainless steel, galvanized sheet(20-175mm);aluminum coil(50-175mm) |

| Material feeding method | Alternating double screw rails feeding |

| Notching type | Controlled by servo motor |

| Notching angle | 30°/120° |

| Flanging type | Pneumatic flanging for right angle |

| Flanging width | 14mm |

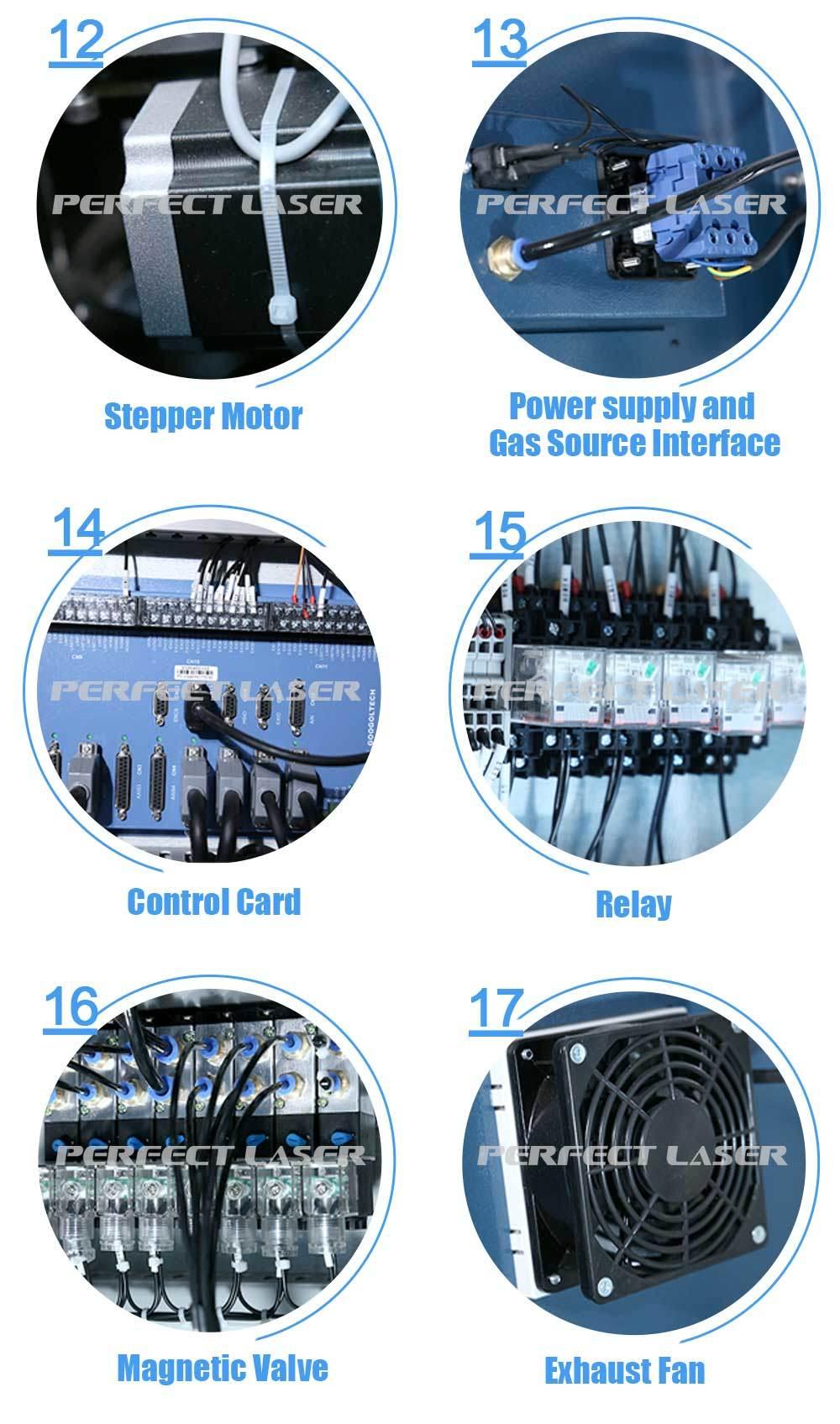

| Servo motor | 4PCs |

| Step motor | 1PCs |

| N.W./G.W. | 800Kgs/900Kgs |

| Dimension | 2290(L)*860(W)*1560(H)mm |

| Software support | DXF/PLT files input, support CAD, TYPE3, CRRELDRAW, ILLUSTRATOR, ect. |

Product Advantage:

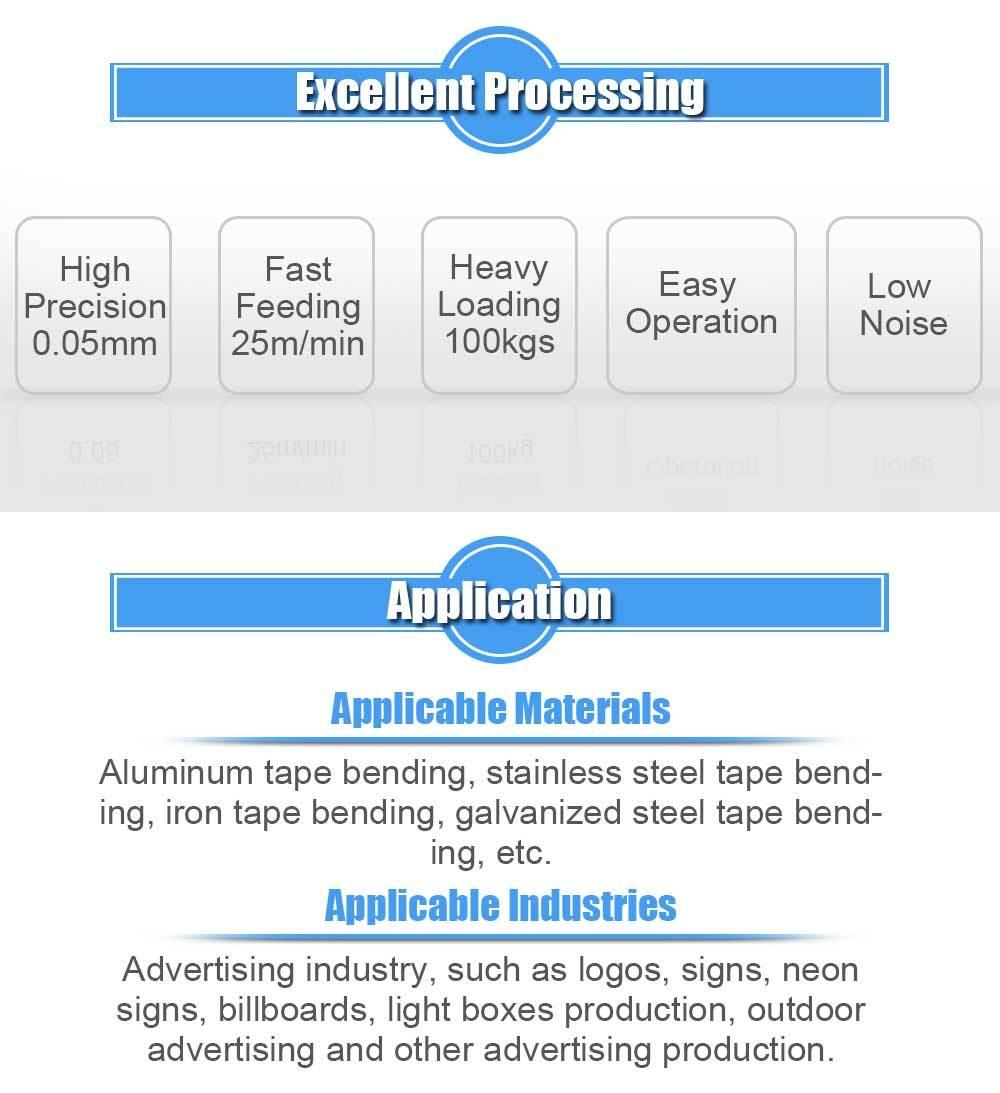

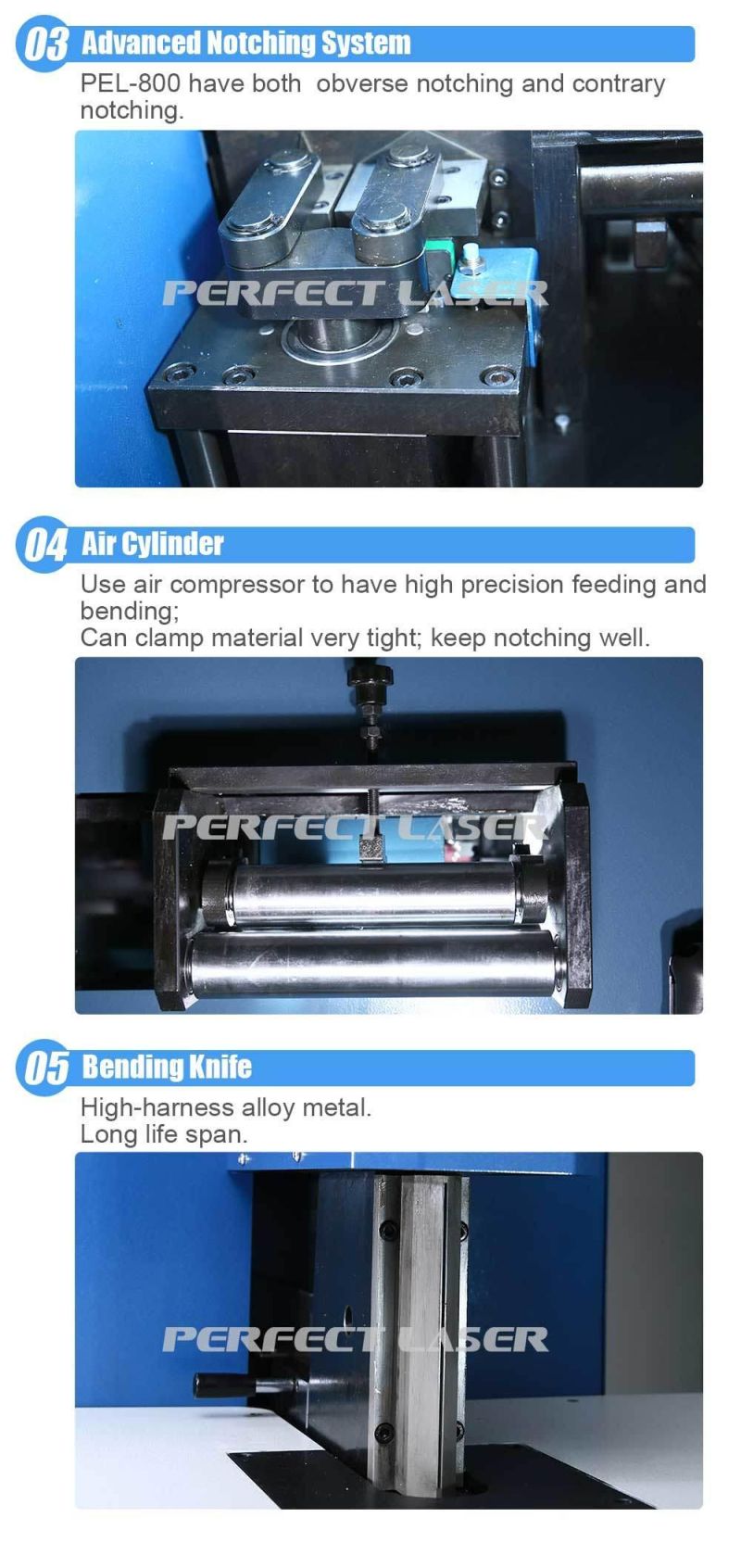

1 .Unique bending type of telescopic alternative bending--it greatly reduces the bending scratch, avoids interference in the bending process and substantially increases the bending torque, which ensures high-precision bending.2. High precision--it is equipped with a closed loop testing device for testing feed length inside, assuring the total length deviation bending less than 0.1mm between the product and original document and also assuring the consistency of manufacturing the same document repetitively. 3.High degree of forming--the coincidence degree reaches as high as 98% with the panel cut by other sorts of precise equipment. 4.Low slotting cost--it uses Germany imported high hardness special stainless steel slotting tool whose using cost is low at RMB0.02 per groove. 5.The unique alternating clamp feeding way features the feeding speed, high accuracy, no indentation, etc. 6.The aluminum brake bender controls the depth of groove by the numerical control axis and meets the needs of different materials and slot thickness. 7.The aluminum brake bender uses servo motor for notching function with high speed, pneumatic flanging for right angle and no burr with notching. 8.Intelligent compensation for bending rebound--it is equipped with intelligent compensation system by Perfect Laser based on their several years of P&D experience. Due to this system, it can assure forming precision for all kinds of materials. 9.Intelligent bending process--it can reduce interference and collision in the bending process by the intelligent inspection system. 10.Lifelong free update of operating software. 11.Processional, high-efficient and considerate service.

Our Service:

1> All of our machines will be full-checked by our quality control department before the shipment.

We make sure that customers will get good products from us. and all of our machine with a 24

months quality guarantee period.

2> We will enclose an "Instruction Book", "Operation Manual" and "Training Video" (in the English version) to you, which is easily understood and handle by the customer.

3> We will offer plenty of online supports, by email, video, telephone, and fax.

4> Our engineer can make a door-to-door instruction training service.

Company Information:

Perfect Laser is a world famous manufacturer of industrial laser &cnc equipment. Since 1995, Perfect Laser focused on the development and production of various types of laser machinery and CNC equipments.

Talented Team

Perfect Laser brings together the world's top professional talent and technology, has a highly qualified international personnel. Set from software development to hardware design, system testing, technical services are completed by professional and technical personnel.

Perfect Laser eatalished 2 R&D center in Changchun and Wuhan City, well-known institutions of higher learning and research institutions at home and abroad, work closely with national 63 patents, a number of the core technological achievements and technical indicators at the international advanced level.

Contact: Betty / Sales Department

Add: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Wuhan, Hubei, China(430200).