Hydraulic Bending Machine for Sheet Metal

Jinan Kaifeng CNC Machinery Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2000, ISO 9001:2008

- Suitable for:Aluminum, Alloy, Carbon Steel, Stainless Steel

- Type:Hydraulic Bending Machine

Base Info

- Model NO.:WD100-4000

- Pressure:100t

- Bending Length:4000mm

- Application:Machinery & Hardware

- Control System:Delem CNC System

- Main Motor:Yaskawa, Japan

- Electrical Components:Schneider Electrical, French

- Product Name:CNC Hydraulic Press Brake

- Transport Package:Customized

- Specification:10.5T

- Origin:China

- HS Code:846229

- Production Capacity:130

Description

Basic Info.

Model NO. WD100-4000 Pressure 100t Bending Length 4000mm Application Machinery & Hardware Control System Delem CNC System Main Motor Yaskawa, Japan Electrical Components Schneider Electrical, French Product Name CNC Hydraulic Press Brake Transport Package Customized Specification 10.5T Origin China HS Code 846229 Production Capacity 130Product Description

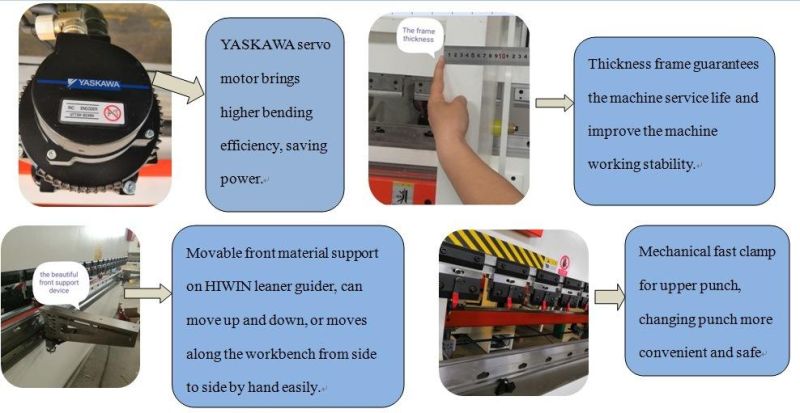

MAIN COMPONENTS

| CNC System | DELEM-DA53 control system, Switzerland |

| Electrical components | Schneider, France / Omron, Japan |

| Grating Ruler | Fagor, Spain |

| Servo motor/Servo drive | Yaskawa, Japan |

| Foot switch | KF, China |

| Hydraulic System/(Assembly) | BOSCH/HOERBIGER, Germany |

| Ball Screw/ Linear guide | HIWIN/PMI/PYM from Taiwan |

| Seals | Walka, Japan |

TECHNICAL SPECIFICATION

| Model: | Unit | WD100-4000 |

| Control Axis | 4 (Y1, Y2, X, R) | |

| Bending force | Ton | 100 |

| Bending length | mm | 4000 |

| Distance between columns | mm | 3400 |

| Stroke | mm | 200 |

| Throat Depth | mm | 550 |

| Open Height | mm | 520 |

| WORKING SPEED: | ||

| Fast speed | mm/sec | 180 |

| Working speed | mm/sec | 9 |

| Return speed | mm/sec | 180 |

| CAPACITY: | ||

| Hydraulic oil standard | / | #46 Anti-wear hydraulic oil |

| Overall dimensions | mm | 4220*1615*2710 |

| Power supply | 380V/7.5KW (As customer requirement) | |

| Weight (Approx) | T | 10.5 |

STANDARD CONFIGURATION

- Integrated into the modern aesthetic concepts of new industrial design, high quality production process, simple and generous appearance.

- The latest high frequency response hydraulic control technology, faster speed, high efficiency and more stable precision.

- Electric hydraulic servo system, full loop controlling the synchronization of the upper beam.

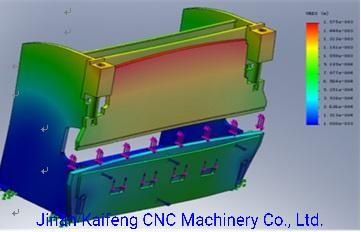

- Quip with VILA automatically crowning device on worktable and deformation compensation device on throat to make sure bending depth and precision.

- Optimizing the validation for the treatment frame and rigidity of whole machine .researching and applying the hydraulic compensation structure ensure precision bending processing.

The frame, combined structure, has been heated processed and highly frequently vibrated. Guarantee the whole precision, rigidity, excellent torsion and stability of the machine. The thick working table plate and ram give the assembly high rigidity. The linear and angle of the finished plate are the same.

Functions

This machine is high-efficiency and high-precision in bending sheet metal. Using different kinds of upper and lower dies can bend all kinds of work-pieces. One slider travel makes a sheet bending and the complicated shape work-piece may be achieved through bending many times.

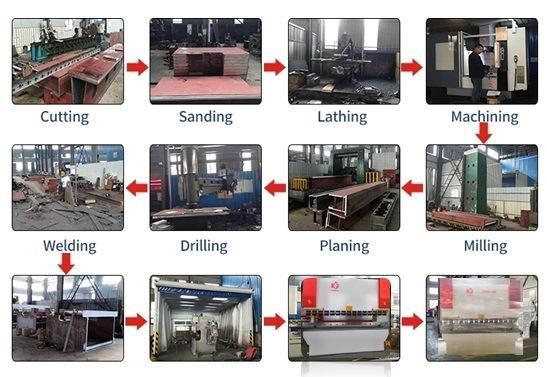

Processing Steps

FAQ:

Q: GUARANTEE PERIOD

A: Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions is caused by customers' incorrect operation, we will provide spare parts at cost price. We can also offer flexible extended warranties according to the actual situation.

Q: AFTER-SALES SERVICES

A: Our engineer can go to your factory for installation and show operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Q: WHY CHOOSE US

A: Many years machine exporting experience, give customer prompt after service feedback .

Self manufactured machine, quality strictly control. OEM service.

Q: What is your payment terms?

A:T/T,L/C, Western union and so on.

Q: How to operate your machine?

A:We will provide operational manual along with the machine, we can also send operation vedio for study. Face to face on line teaching is also available.

Q: How to choose a model?

A:Send us your plate material, max thickness, max width then we can give you suggestion.

Q: How long is your production time?

Normally standard model delivery time is 30 working days, for bigger model we will need 45 or 50 working days. For urgent order,we can finish at 15 days. Need to discuss by each order.

Q:Do you test your machine before delivery?

A: Every machine will need 24 hours running,then engineer debug before packing.

experience in this field with professional technical supporting and oriented service.

We welcome your visit to us any time.

If you have any question,please feel free to contact us!