Multi-Heads Non-Ferrous Metal Plate CNC Flame Cutting Machine (ZLQ-10A)

Wuhan Lan-Sun Technology Co., Ltd.- After-sales Service:12month

- Warranty:12month

- Certification:CE, ISO 9001:2000

- Condition:New

- Control:Automatic

- Application:Metal

Base Info

- Model NO.:ZLQ-10A

- Connected Shaft Number:3-Shaft

- Style:Gantry

- Type:CNC

- Plasma Power:China; Hypertherm; Maxpro200

- Guide Rail:Made in Taiwan(Can Be Extend)

- Cutting Gas:Oxygen & Acetylene,Propane

- File Transmission:USB

- Place of Origin:Hubei, China (Mainland)

- OEM:Brand You Want

- Drive Mode:Double Side

- Cutting Mode:Flame; Plasma; Flame&Plasma

- Numeral Control System:Lansun, Hypertherm, Micro Edgepro

- Type for Cutting Machine:CNC Cutting Machine

- Type for Fold-Bending Machine:CNC Cutting Machine

- Automation:Automatic

- Transport Package:Wooden Case

- Specification:CE

- Trademark:LANSUN

- Origin:Hubei, China

- HS Code:84569010

- Production Capacity:100sets,Month

Description

6.0m ( can be customized) 1.Steel hollow beam design ensures good heat dissipation without deformation; HEIGHT CONTROLLER Multiple cutting torches can be configured. Both flame and plasma torches are optional to meet the needs of cutting different materials in a range of thickness. 1. 10.4 inch LCD display; Features: Portable and lightweight cnc flame/oxy/gas cutting machine. This cutter adopts single drive and lineal guide. It is small bodily movement type, can be put upon the metal plate to be cut, needn't fixed plant, operate easily. Application: It can cut mild steel (flame cutting) and high carbon steel, stainless steel, aluminum, copper and other non-ferrous metal (plasma cutting), etc, be widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive etc. 1. Are you factory or foreign trade company? Our factory is located in Wuhan, Hubei. We will meet you at airport or train station. Warmly welcome to visit us! (2) With plasma cutting: air compressor. Plasma power is purchased by us, so that we can debug online, and we all need very good plasma power to ensure quality.Effective Cutting Width (X axis) 3.2m Effective Cutting Length (Y axis) 4.5m Cutting Mode Flame only; Plasma only; Flame and Plasma Drive Mode Bilateral-side Drive Method Rack and pinion drive for X and Y axes Flame Cutting Thickness 5-200mm Plasma Cutting Thickness 1-60mm (according to the specification of plasma power source) Cutting Speed Flame: 0-3500mm per minute; Plasma: 0-8000mm per minute Moving Precision 0.01mm per step Power Source (option) 220V 50Hz 500-1000W Nesting Software (option) INTERGNPS, FASTCAM Cutting Gas Acetylene, Propane Plasma Gas Pressed air, Oxygen, N2 Automatic Torch Height Controller(option) CHC600 Capacitive height controller for flame cutting PHC330 Arc voltage height controller for plasma cutting

Detailed description:

Machine body structure

2. Box weldment structure process tempering ensures excellent rigidity and intensity;

3. Double drive adopts symmetrical structure.

Flame:Electric height adjusting system.

Plasma:Arc voltage height controller.

CNC System

2. USB port support, figures display;

3. Indicator lights showing working condition;

4. Operation menu displayed instantly on monitor;

5. Easy figures programmed directly.

Beijing or Shanghai or American Brand CNC system is oPtional

Drive Model Transmission

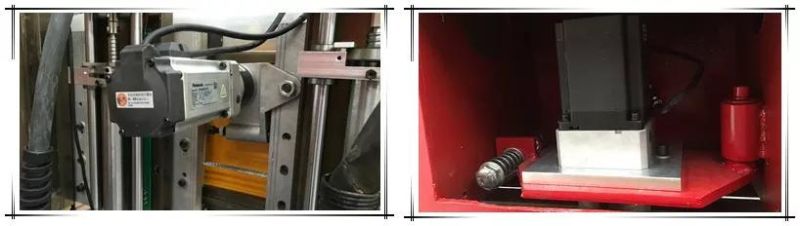

Japan AC servo motor 1.Rack and gear mesh transmission. High stability of walking 2.Gear box: SEW, high output torsion low noise.

Convenient maintenance 3.Horizontal torch transmit by steel belt.

4. These devices are durable and long life device.GUIDE RAIL

Material :U71Mn

Intensity:No less than700N/mm²;

Loading capacity no less than = 10T(per meter),

Rail tensile strength no less than 883Mpa,

Compression strength no less than 1000T.

Process mode:High precision grinder.

Longitudinal rack accuracy :7grade

Pitch:CP6

Cutting sample:

Certifications:CE&ISO 9001Certificate

Packaging & Shipping:

The main cabinet, auxiliary cabinet and cutting head have a packing box: 0.72m×0.68m×0.5m;

There is one packing box for the beam and guide rail: 3.37m×0.35m×0.3m (standard format);

A packing box for the header: 2.54m×0.3m×0.3m (standard format);

Our Factory:

FAQ:

We are over 17 years experienced manufacturers, large-scale production of CNC cutting machine.

2. Where is your factory located? How can I visit there?

3. What's the quality of your products?

We are very focused on the quality of the products, All spare parts of this machine come with best brand and best quality, after completing the installation we will test the machine for 48 hours. Our factory has gained CE, ISO9001 authentication.

4. What shall we do if don't know how to operate your machine after bought from you?

We have detailed installation and operating instructions attached, also comes with video, it is very simple. We have telephone and email support at 24 hours a day.

5. What other things also need after we bought your machines?

(1) With flame cutting: oxygen and fuel gas.

6. What are your payment terms?

We support T/T, L/C, Western Union, Alibaba Trade Assurance and so on. Other ways can also be received after we both sides discussion and agreement.