Angle Programming CNC Metal Plate Bender/Bending Machine Wc67K-63/2500

Anhui ZhongDe Machine Tool Co., Ltd.- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2008, CE

- Automation:Semi-Automatic

- Suitable for:Aluminum, Alloy, Carbon Steel, Stainless Steel

- Type:Press Brake

Base Info

- Model NO.:WC67K-63,2500

- Product Name:Angle Programming CNC Plate Bender Wc67K-63,2500

- Model:Wc67K-63,2500

- CNC Controller:E210 CNC

- Max Bending Capacity:630 Kn

- Max Bending Length:2500mm

- Transport Package:Steel Fixed

- Specification:WC67K-63,2500

- Trademark:ZDMT

- Origin:China

Description

Basic Info.

Model NO. WC67K-63/2500 Product Name Angle Programming CNC Plate Bender Wc67K-63/2500 Model Wc67K-63/2500 CNC Controller E210 CNC Max Bending Capacity 630 Kn Max Bending Length 2500mm Transport Package Steel Fixed Specification WC67K-63/2500 Trademark ZDMT Origin ChinaProduct Description

Angle Programming CNC Plate Bender ZDPK-6325 (WC67K-63/2500)

Main functions and features

· Total steel-welded structure and stress elimination by vibration.

· High mechanical strength and strong rigidity.

· Ram stroke hydraulic approaching downward,stable and reliable.

· Mechanical stop and steel torsion bar to maintain synchronization and high precision.

· Movement of backgauge and ram stroke is servo controlled by E210 CNC system.

· The function of angle programming of E210 will bring high bending efficiency.

· X axis with ball screw,linear rail,servo motor and steel synchronous belt,can improve X axis positioning precision and speed.

· With Y axis servo positioning function,it can accurate and effective improve Y axis accuracy and working efficiency.

Related configuration with details· Front view of ZDPK-6325

· E210 with the function of angle programming will bring high bending efficiency

Main features of E210 controller:

Program memory of up tp 100 programs,25 steps per program

Tool library:20 dies

Conventional press brake control

Angle programming and automatic bending position calculation

Back gauge allowance compensation

Dual servo system control

Flexible I/O configuration

Free group valve setting

One side positioning

Retract function

Auto reference search

Power-down memorization

mm/Inch

Chinese/English

Diagnosis function

· High precision quick clamps,it is for easy operation of removing and changing upper punch tools.

· Nylon front support to avoid scractch of sheets and improve the bending process.

· With France Schneider electrics,stable and durable.

· Domestic top brand motor and pump,with strong force and low noise.

· Domestic top brand Harbin bearing,with high quality.

· With imported hydraulic valve,stable and durable.

· With Y axis servo positioning function,it can accurate and effective improve Y axis accuracy and working efficiency.

· With ZDMT latest torsion bar synchronization device,high strength and adjustable,patented technology.

· Thicker type backgauge structure,adjustable stop fingers,they can not only slide on linear rail but also go up or down if needed,adapt to different moulds.

· X axis with ball screw,linear rail,servo motor and steel synchronous belt,can improve X axis positioning precision and speed.

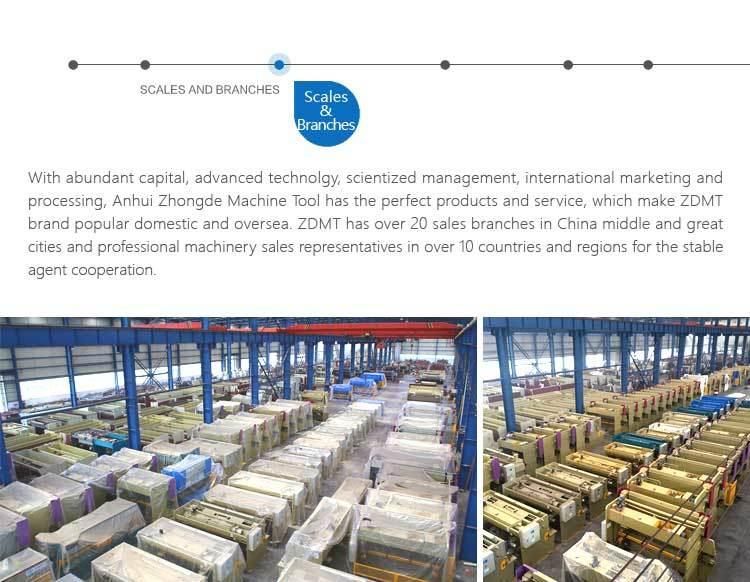

Company Informations: