-

Competitive Welding Torch (H01-2)

0.001-0.1300H01-62-60.14-0.38125-3450.20-0.40400H01-126-120.45-1.2410-1100.40-0.70500H01-2012-201.6-2.61450-23500.60-0.80600ModelThickness(mm)Oxygen pressure(Mpa)Acetylene pressure(Mpa)Propane pressure(MPa)Length(mm)G02-100C3-3000.2-0.670.015-0.050.02-0.06500* Professional recommendation &person

-

CNC Plasma & Flame Cutting Machinery

Basic Info. Cutting Mode Optional Plasma and Flame

-

Gantry CNC Plasma Cutting Machine and Flame Cut Metal Inverter Plasma Cutter

H-beam steel or cement base, standard configuration is H-beam steelAttachment partswithout Rotary AxisWith Flame cutting system20without Drilling heads21without Air compressing machineThe production processCutting sample displayCompany ProfilePackaging & Shippingstand exporting packing1.Outside

-

Automatic Gantry Cutting Machine/CNC Flame Plasma Cutting Machine

ModelDrive wayTwo rails' distance (mm)Effective cutting width (mm)Cutting thickness (mm)Cutting speed (mm/min)Max speed (mm/min)Cutting torch vertical route(mm)Flame cuttingPlasma cuttingFlame cuttingPlasma cuttingCNCI-2700Single side270018006-200Depending on plasma power model, optionla100-750Depen

-

CNC Heavy Duty Metal Cutter Plasma Cutting Machine

************* Gantry plasma/flame cutting machine Cross Beam Length(X axis) 4500mm (can be customed as user's demand) Longitudinal Rail Length(Y axis) 8500mm (Rail can be customed as user's demand) Effective Cutting Width (X axis) 4000mm(can be customed as user's demand) Cutting Mode Flame only; Pla

-

Oxygen Fuel Flame Cutting Torch for CNC Cutting Machine

Basic Info. Model NO. LT-GJ-ZT-180

-

CNC Flame Plasma Cutting Machine for H Beam

Basic Info. Weight (Kg) 1500

-

H-beam steel or cement base, standard configuration is H-beam steelAttachment partswithout Rotary AxisWith Flame cutting system20without Drilling heads21without Air compressing machineThe production processCutting sample displayCompany ProfilePackaging & Shippingstand exporting packing1.Outside

-

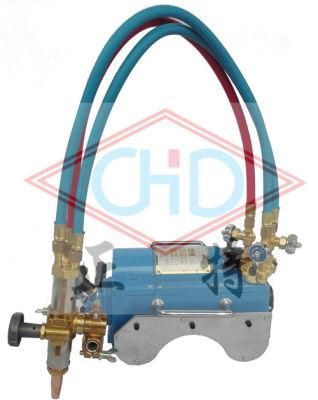

Magnetic Gas Cutting Machine for Pipe Cg2-11c

1.Main Unit1SET2.Control box13.Cutting torch unit1SET4.Oxyacetylene joints1PCS9.Cutting Torch1#,2#,3#1PCS10. Introduction, Quality certificationEach 1 PCS5. Assembly 1. Torch 2. Torch Holder 3. Rack 4. Mover System 5. Main Body Part: Transmission and Control System 6. Heat Shield