Rebar Bender/Wire Bending Machine/Automatic Stirrup Bender Gw50 Digital Screen

Ningbo Max Machinery Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2000, ISO 9001:2008, CE

- Automation:Automatic

- Suitable for:Plastic, Rubber, Aluminum, Alloy

Base Info

- Model NO.:GW50

- Type:Hydraulic Bending Machine

- Key Selling Points:Automatic

- Singlet Processing Capacity:5~13mm

- Double Processing Capacity:5~10mm

- Maximum Towing Speed:84m,Min

- Max Bending Angle:180

- Length Accuracy:1mm

- Maximum Bending Speed:800

- Power:26.7kw

- Average Power:5.5kw,H

- Transport Package:Carton

- Specification:50,60hz

- Trademark:MAXMACH

- Origin:Ningbo, China

- HS Code:8462219000

- Production Capacity:1000PCS,Month

Description

Basic Info.

Model NO. GW50 Type Hydraulic Bending Machine Key Selling Points Automatic Singlet Processing Capacity 5~13mm Double Processing Capacity 5~10mm Maximum Towing Speed 84m/Min Max Bending Angle 180 Length Accuracy 1mm Maximum Bending Speed 800 Power 26.7kw Average Power 5.5kw/H Transport Package Carton Specification 50/60hz Trademark MAXMACH Origin Ningbo, China HS Code 8462219000 Production Capacity 1000PCS/MonthProduct Description

| Singlet processing capacity: | 5~13mm |

| Double processing capacity: | 5~10mm |

| Max bending angle: | ±180° |

| Maximum towing speed: | 84m/min |

| Maximum bending speed: | 800°/sec |

| Length accuracy: | ±1mm |

| Average power: | 5.5kw/h |

| Power: | 26.7kw |

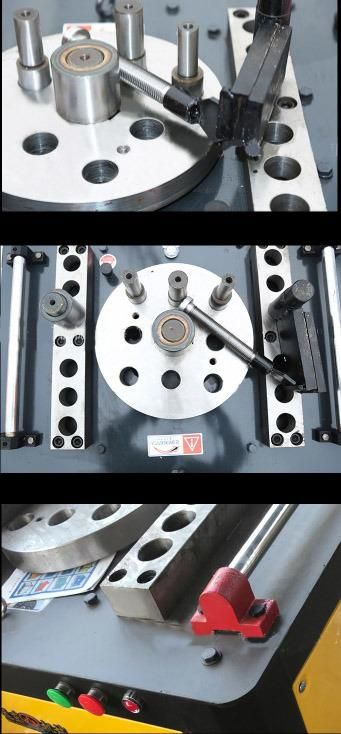

Product features

1.automaticly straightening

2.automaticly bending

3.automaticly measure

4.automaticly cutting

5.can store more than 100 different graphics

Advantage

1.We have 10 years of production experience, the technology and process are very mature.

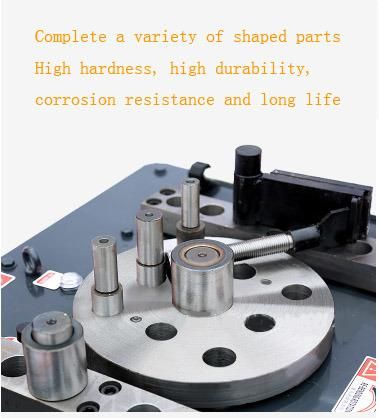

2.Vulnerable parts are professionally treated at high temperatures for high strength and wear resistance

3.Double wire processing, excellent efficiency

4.Easy to understand, with intuitive instructions and instructional videos.

5.Intelligent alarm system to prevent misoperation and easy maintenance.

6.High-power motor to ensure working accuracy and speed.

7.The servo motor and drive system is developed and manufactured by PHASE, Italy.

8.High efficiency in the after-sales department, our engineers are always on-line and can help abroad.