Sheet Metal Hydraulic Cutting Machine with Delem Da360s System

Nanjing Shanduan Cnc Machine Tool Co., Ltd.- Automation:Automatic

- Certification:CE

- Condition:New

- Warranty:2 Years

- Transport Package:Standrad

- Trademark:ysdcnc

Base Info

- Model NO.:RAS-6×3200

- Origin:Nanjing

- HS Code:8462312000

- Production Capacity:600 Sets,Year

Description

Basic Info.

Model NO. RAS-6×3200 Origin Nanjing HS Code 8462312000 Production Capacity 600 Sets/YearProduct Description

shear sheet metal hydraulic cutting machine with DELEM DA360S system

hydraulic shearing machine

Nanjing Shanduan CNC Machine Tool Co., Ltd is one of the Top 3 press brake and shearing machine in China, which specializing in manufacturing and marketing of press brake,shearing machine,press machine, square duct production line LINE5,4,3,2,1;spiral duct machine, locking forming machine;folding machine,plasma cutting machine, power press,ironworker,hydraulic notching machine, beading machine,flange forming machine,shearing machine & press brake,Blade/Mold, etc.

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

| Website: www.ysdcnc.com |

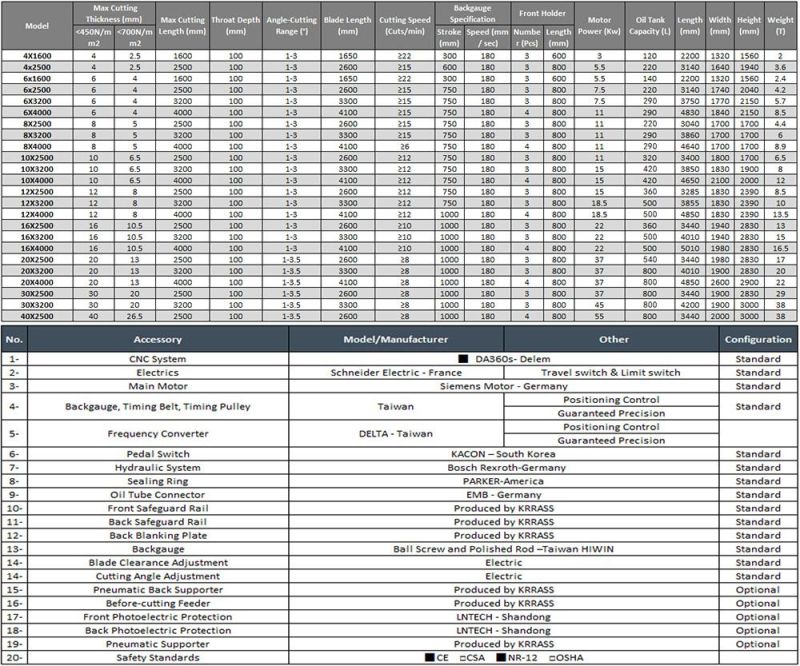

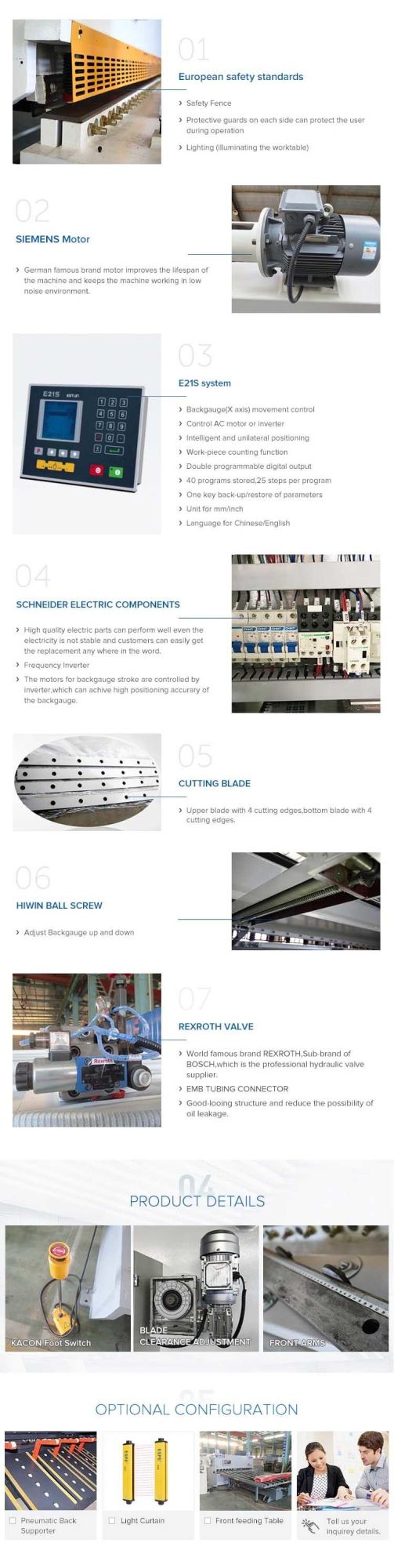

1. Main Features:Streamlined design originated from EU, main structure consists of rack, cutter holder, oil cylinder, hydraulic controller, backgauge and other components. Finite-element analysis of main parts, Welding parts uses tempering, vibration and other processing methods to eliminate stress ensuring the structural strength and rigidity of each component;

Cutter holder use three-point support rolling guide rail, reducing the friction to the greatest extent, and realizing seamless rolling during cutter holder moving.

Leftmost front holder configured with verticality regulator and front positioning device, easy operation and high efficiency;

Simple and effective blade adjusting mechanism rearranges blade clearance by CNC system, improving the cutting quality.

Fine ball screw and rod structure, good-performance frequency converter is applied to positioning X axis to ensure accuracy, unique designed timing transmission mechanism, stable and reliable.

Light and shadow line is conductive to manual scribing for cutting; stable and reliable hydraulic transmission; integrated hydraulic system is able to significantly alleviate problems causing by hydraulic fluid leakage.

Made by high-quality alloy tool steel capable enough to against impact load and high wear resistance when cutting;

With reference to ergonomic design, easy operation with CNC system surface, improving the operation precision and comfortability;

rolling ball workbench to reduce friction and prevent work piece surface from scratching; unique and practical safety guard, line with safety specifications, protect the personal safety; delicate design, petty work piece can be done easily by hand.

2. Standard Configuration:Delem DA360s CNC controller

Electric controls backgauge X-axis

DELTA frequency converter and controller

HIWIN ball screw and polished rod, control accuracy of 0.05mm.

Controller cantilever and front supporter

Germany Bosch Rexroth integrated hydraulic valve

Germany EMB oil tube connector and high-pressure hose

Germany Siemens main motor

France Schneider electrics

Hydraulic and electrical overload protection

Light aligning

Blade materials ( 6CrW2Si )

South Korea KACON pedal switch

Cutting angle adjustment

Electrically adjusts the blade clearance

3. Safety Standards:

Safetry standards (2006/42/EC)

Open electric cabinet and front safeguard door to cut off power

South Korea KACON pedal switch ( safety grade 4 )

Rear metal safeguard rail, CE standard

Safety relay monitors pedal switch, safety protection

4.Holland DELEM DA360S CNC system:

4.7"monocolor LCD display

High-quality metal film switch

Restoring 100 programs, each program have 25 steps

Backgauge control, cutting angle control, cutting clearance control, cutting stroke control

Each axis can be moved manually

One-key backups and restored parameters

Pressure control

Metric or imperial measurements

Major Import configuration list:

| NO | UNIT | NUMBER | MARK |

| 1 | CONTROL SYSTEM | 1set | E21S (ESTUN) |

| 2 | HYDRAULIC SYSTEM | 1set | REXROTH VALVE |

| 3 | Ball screw | 2sets | Taiwan HIWIN |

| 4 | Sealing ring | 1set | FIETZ, Japan, VALQUA, Japan. |

| 5 | Major electrical components | 1set | SCHNEIDER |

| 6 | Motor | 1 set | SIEMENS |

| 7 | CUTTING BLADE | 1 set | YSDCNC |

Random tools/documents:

| Serial No. | Name | Quantity | Remark |

| 1 | Main unit | 1 | Including one set of upper and lower die, front plate holder and foot switch |

| 2 | Grease gun | 1 | |

| 3 | Button key | 2 | |

| 4 | Key to door lock | 2 | |

| 5 | Product instructions | 1 | |

| 6 | certificate of quality | 1 | |

| 7 | Packing list | 1 | |

| 8 | Foundation bolt | 4 sets | Including nuts and washers |

| 9 | O-type sealing ring | 16 |

hydraulic shearing machine