Hydraulic Shearing Machine with E21s Nc System for Metal Sheet Cutting Machine

Anhui ZhongDe Machine Tool Co., Ltd.- Automation:Semi-automatic

- Certification:CE, ISO 9001:2008

- Condition:New

- Warranty:1 Year

- Model:QC12y-4X2500

- CNC Controller:E21s

Base Info

- Model NO.:QC12Y-4X2500 E21S

- Transport Package:Base Framed by Steel and Plastic Bag

- Specification:1 Unit

- Trademark:ZDMT

- Origin:China(Mainland)

- Production Capacity:50unit,Month

Description

Basic Info.

Model NO. QC12Y-4X2500 E21S Transport Package Base Framed by Steel and Plastic Bag Specification 1 Unit Trademark ZDMT Origin China(Mainland) Production Capacity 50unit/MonthProduct Description

QC12Y-4X2500 (ZDS-425) hydraulic shearing machineQC12Y-4X2500 (ZDS-425) Hydraulic Sheet Metal Cutting Shearing Machine,the maximum thickness of cutting mild steel is 4mm,the maximum length is 2500mm.

Steel plate welded structure,hydraulic transmission and accumulator return strock;Characterized by easy operation,reliable performance and fine appearance;

With E21S simple CNC controller,E21S can control the movement of backgauge,achieving efficient and highly precise positioning;

The blades with high tensile strength,can cut mild steel and stainless steel.

Main function and features

Steel plate welded structure,hydraulic transmission and accumulator return strock.

Characterized by easy operation,reliable performance and fine appearance.

Indicator based gap adjustment of blades,convenient and swift.

Shadow light alignment.

Top blade could be adjusted for full stroke or shorter ones.

Fence guard for personnel safety.

E21S as the simple CNC controller,it can control the movement of backgauge,achieving efficient and highly precise positioning.

Related Configuration with details

1.Front view of QC12Y-4X2500 (ZDS-425) hydraulic swing beam shear

2.Rear view of QC12Y-4X2500 (ZDS-425) hydraulic swing beam shear

3.E21S simple CNC controller

4.Bite type tube fittings is used to avoid disadvantages of uneasy maintenance etc that caused by welding

5.Main motor

6.Taiwan high quality SHIHLIN frequency inverter,lower frequency and more energy-efficient,with quick positioning

7.Manual adjustment of blade clearance device,with high precision

8.High quality hydraulic valve,with high quality and no oil leakage

9.Safety switch outside the electric cabinet door,will automatical outage when overload

10.High quality electrics,with stable quality and long life

11.Blade clearance adjustment device,with high quality;And use Harbin bearing,with long life and high precision

12.Penetration guard fence around the shear,not only protect the safety of operator but also observe the shearing position

13.Emergency stop button on the back of the shear machine,to protect the personnel safety

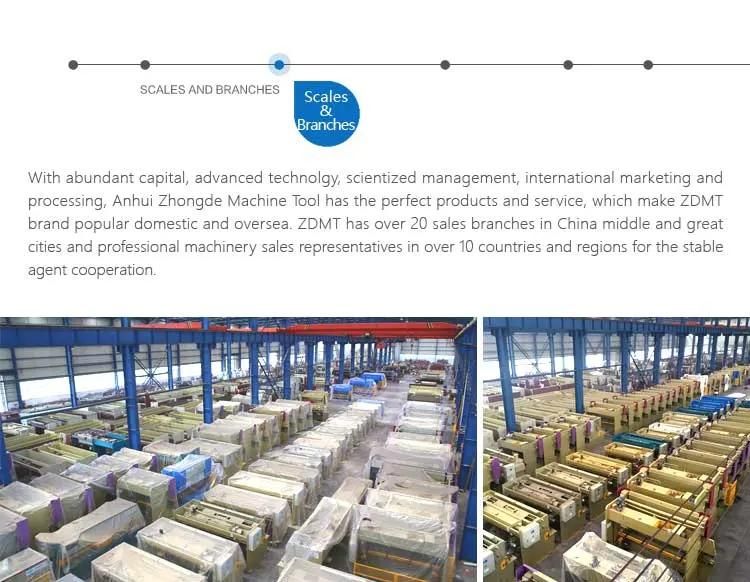

Company profile: