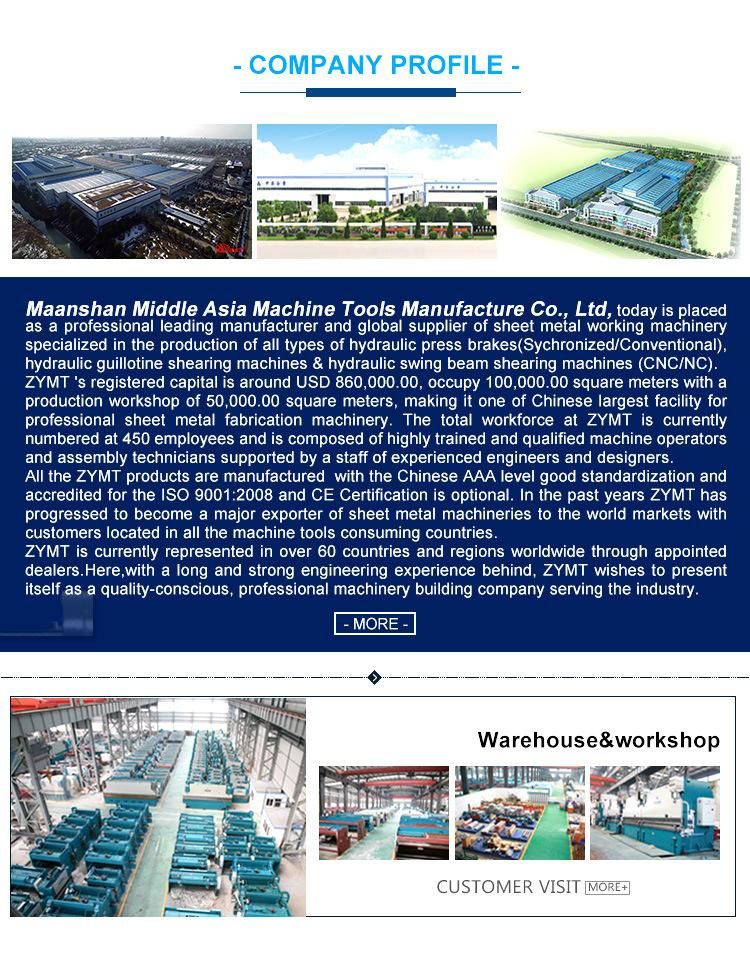

Sheet Metal Hydraulic Guillotine Shearing Machine/Cutting Machine

Maanshan Middle Asia Machine Tools Manufacture Co., Ltd.- Automation:Automatic

- Certification:CE, ISO 9001:2008

- Condition:New

- Warranty:1 Year

- Type:Shearing Machines

- Key Selling Points:Multifunctional

Base Info

- Material:Weld Steel

- Weight:47000kg

- Dimension(L*W*H):6830X2700X3300mm

- After-Sales Service Provided:Online Support

- Voltage:380V,220V,440V,415V

- Variable Cutting Angle:1-3.5

- Hydraulic Valve:USA First

- Controller:Italy Maper Mpf

- Seal Ring:Japan Brand

- Cutting Thickness:20mm

- Rated Power:37kw

- No. of Plate Holders:30PCS

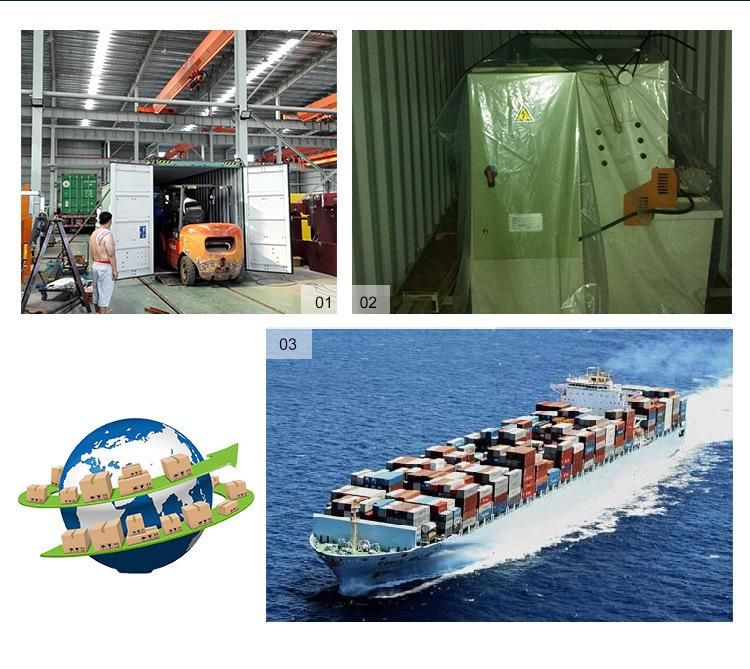

- Transport Package:Seaworthy Packing

- Specification:CE ISO GSP CQC

- Trademark:ZYMT

- Origin:Anhui, China

- HS Code:8462319000

- Production Capacity:120 Set,Sets Per Month

Description

Basic Info.

Material Weld Steel Weight 47000kg Dimension(L*W*H) 6830X2700X3300mm After-Sales Service Provided Online Support Voltage 380V/220V/440V/415V Variable Cutting Angle 1-3.5 Hydraulic Valve USA First Controller Italy Maper Mpf Seal Ring Japan Brand Cutting Thickness 20mm Rated Power 37kw No. of Plate Holders 30PCS Transport Package Seaworthy Packing Specification CE ISO GSP CQC Trademark ZYMT Origin Anhui, China HS Code 8462319000 Production Capacity 120 Set/Sets Per MonthProduct Description

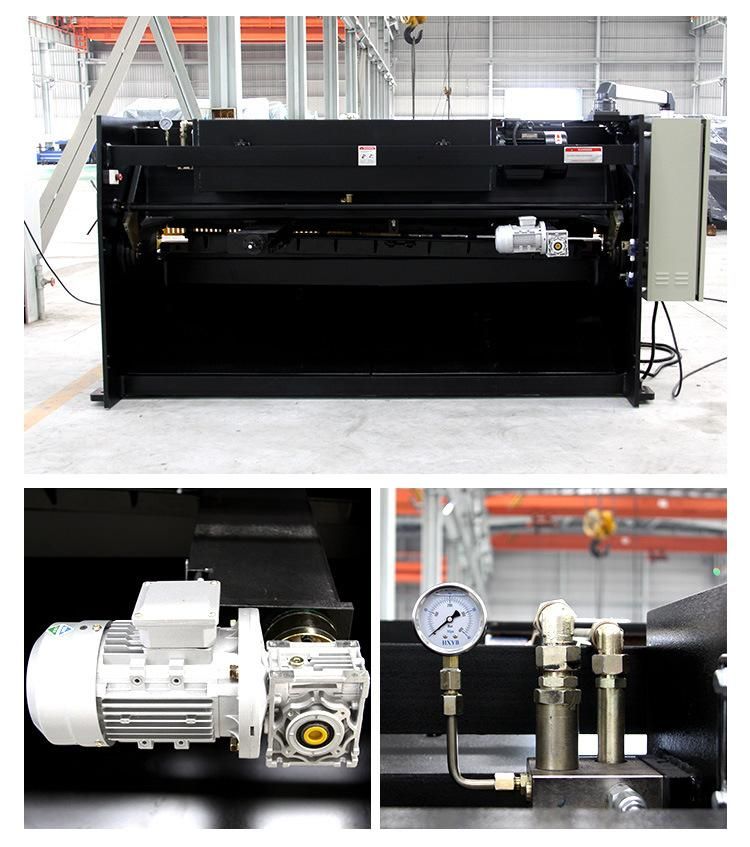

Sheet Metal Hydraulic Guillotine Shearing Machine/Cutting Machine

The shearing machine is provided for cutting metal-steel sheet plates, and capacity is based on plate strength of 450N/mm2. Please correct the plate thickness if cut other material plate with different strength. Sheet plate welded structure is adopted, easy operation and reliable performance. Cutting is driven by hydraulic pressure, and return is by nitrogen gas cylinder, which can protect the machine from overload. Blade gap with indicator for a handy and prompt adjustment. Alignment device with lighting, cutting stroke can be adjusted to improve the efficiency of cutting narrow plates. Front support arms and back gauge are equipped. The back gauge is mechanic transferring, position is positioned by NC controller through the encoders. The front supporting arms are ruler counted. Rolling material support ball is provided on worktable to minimize fish tail with sheet bar and to reduce frictional resistance.Installed safety fence, ensure the operation safety.

Controllers

160x160 LCD display

Backgauge control

Control for general AC motors , frequency inverter

Intelligent positioning

Stock counter roaram memory of up to 40 programs , up to 25 steps per program

One side positioning

Retract function One key backup / restore of parameters

mm / inch

Chinese / English

sandard Equipments

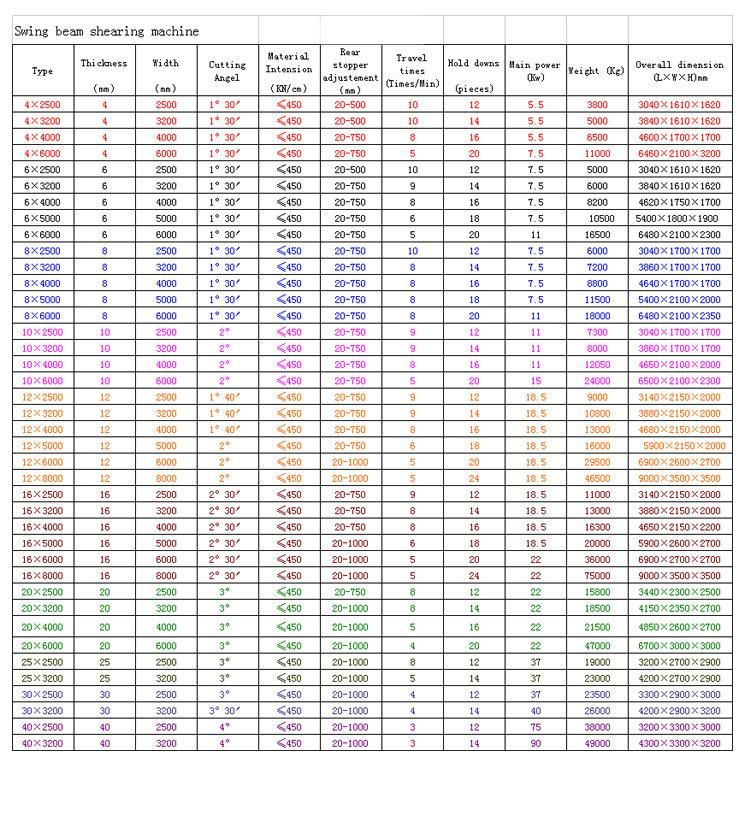

Main Motor : Famous Brand

Hydraulic valves : First , USA

Pump : Vickers , USA / Sunny USA

Main electrics : Famous Brand

Ball screw : Famous Brand ( controller up to E200S with linear guide )

Seal ring : DZ Taiwan / NOK Japan

Foot Switch : Famous Brand South Korea

Front support with measure ruler

Main features of our NC shearing machine as follows:

1. Fully steel welded structure, with excellent rigidity and stability;

2. Assisting blade pedestal on worktable is convenient for micro adjustment;

3. Support ball is provided on worktable convenient operating for rolling plate;

4. Provided with counting function for shearing to decrease the numerous artificial counting;

5. Advanced hydraulic integrated system is employed and the pipeline connection is minimized to ensure the system reliability and safety;

6. International standard electrics and switches;

7. Front arms with ruler fixed on worktable;

8. Blades gap adjustment by hand wheel;

9. Motorised back gauge, reduce speed through gear;

10. Various brands of NC controllers for options: Estun E21S / E200S, Delem DAC310, DAC360, Elgo P40, Maper HT071, ect.

1, Q: Are you factory or trading company?

A: We are factory of press brake(bending) machine ,shearing machine and fiber laser cutting factory was established in 1988, with more than 30 years producing experience.

2, Q: What's your payment?

A: T/T, 30% deposit in advance, 70% balance before ship.

Irrevocable L/C at sight

3, Q: What's about delivery time?

A: For small model press brake, usually 15-30 days after received 30% deposit.

For big model press brake, usually 40-120 days after received 30% deposit.

4, Q: We don't know how to use the machine, can you help us?

A: 1, We will send machine operation manual with machine;

2, If customer require, we will send technician to your factory teach you how to use it and maintain it;

3, You can send technician or workers to our factory, we will teach then how to use and maintain the machine.

5, Q: We are worry about the machine quality?

A: Our machine warranty is 2 years. Before ship the machine, we will test it about 7-10 days, when you received it,you can use it directly, no need test it again.