Manshan Factory CNC Hydraulic Sheet Metal Cutting and Bending Machine

Maanshan Middle Asia Machine Tools Manufacture Co., Ltd.- Condition:New

- Certification:ISO 9001:2008, CE

- Automation:Semi-Automatic

- Suitable for:Aluminum, Carbon Steel, Stainless Steel

- Type:Hydraulic Bending Machine

- Standard Nc Machine:E21 Controller

Base Info

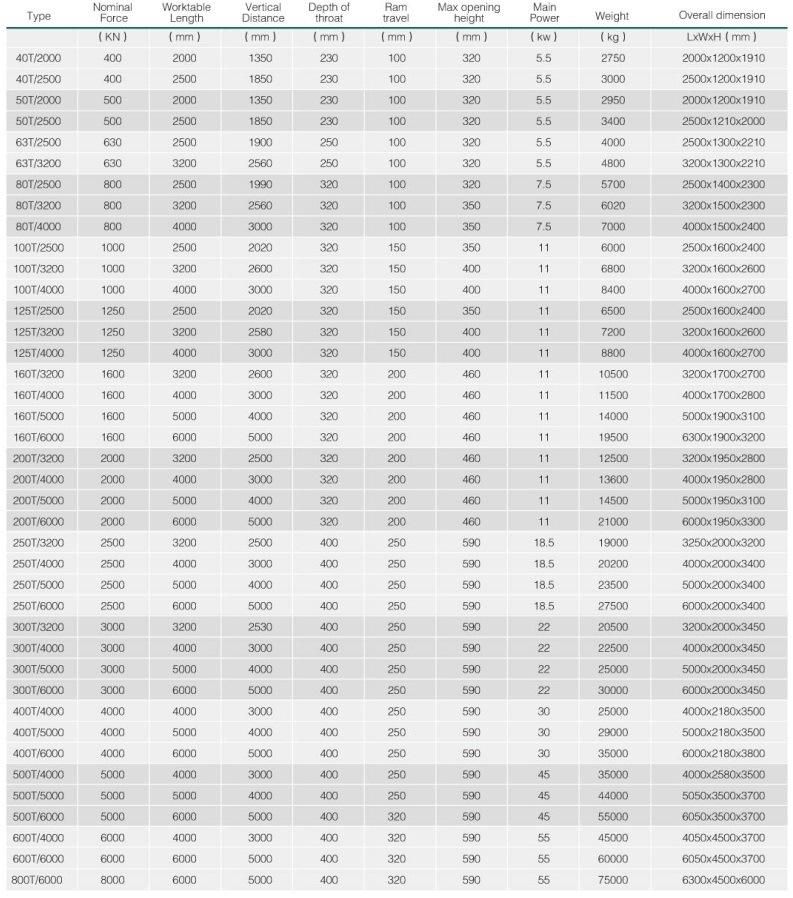

- Model NO.:WC67K-200T,4000

- Backgauge Travel:500mm

- Controller with Movable Arm:Yes

- Front and Back Protection Fence:Front and Back Protection Fence

- Main Motor:Siemens Germany

- Electrics:Schneider France

- Ball Screw:Hiwin Taiwan

- hydraulic Valve:Rexroth Germany

- Pump:Sunny USA

- Footswitch:Karcon South Korea

- Transport Package:Plastic Cover

- Specification:CE, ISO, SGS

- Trademark:ZYMT

- Origin:Anhui, China

- HS Code:8462299000

- Production Capacity:3000 Sets,Year

Description

Installation Services are available with all ZYMT machines. We dispatch technician to customer's factory for installation and preoperation of machines. ( Customers only need to pay the airfare and hotel )

Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments.

Machine warranty is 2 years. We offer flexible extended warranties if needed.