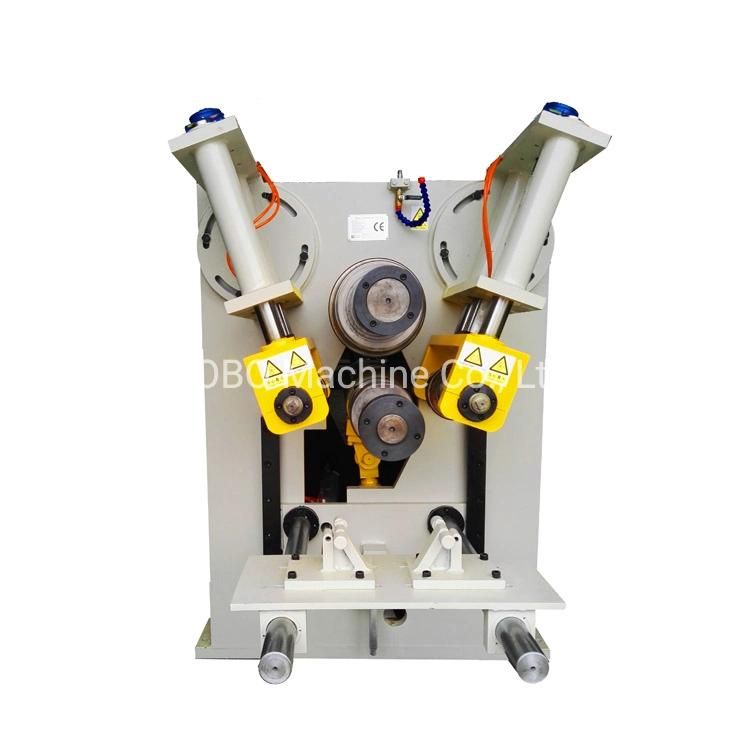

Wheel Roll Bender for Sale in China (WRM-II)

BOBO Machine Co., Ltd.- Condition:New

- Certification:ISO 9001:2000, CE

- Automation:Semi-Automatic

- Suitable for:Copper, Aluminum, Carbon Steel, Stainless Steel

- Type:Hydraulic Bending Machine

- Machine Name:Wheel Roll Bender

Base Info

- Model NO.:WRM-II

- Model Name:Wrm-II

- Control Way:PLC Control

- Rolling Diameter:22.5-38"

- Rolling Width:7.5-20"

- Rolling Thickness:6mm [20" Rim]

- PLC Control:GM, USA.

- Productivity:100-200 Pics,Hour

- Power:18.5kw

- Air Switch and Contactor:GM, USA

- Transport Package:Wooden Package

- Specification:GB

- Trademark:BOBO

- Origin:China

- HS Code:8455229090

- Production Capacity:6 Sets, Year

Description

Basic Info.

Model NO. WRM-II Model Name Wrm-II Control Way PLC Control Rolling Diameter 22.5-38" Rolling Width 7.5-20" Rolling Thickness 6mm [20" Rim] PLC Control GM, USA. Productivity 100-200 Pics/Hour Power 18.5kw Air Switch and Contactor GM, USA Transport Package Wooden Package Specification GB Trademark BOBO Origin China HS Code 8455229090 Production Capacity 6 Sets/ YearProduct Description

Configuration: Three rollers-force rolling. Two-roller force feeding, one roller to control flexibility, with re-feeding prevent device and simple planishing device. Feeding manual, auto unloading by cylinder.

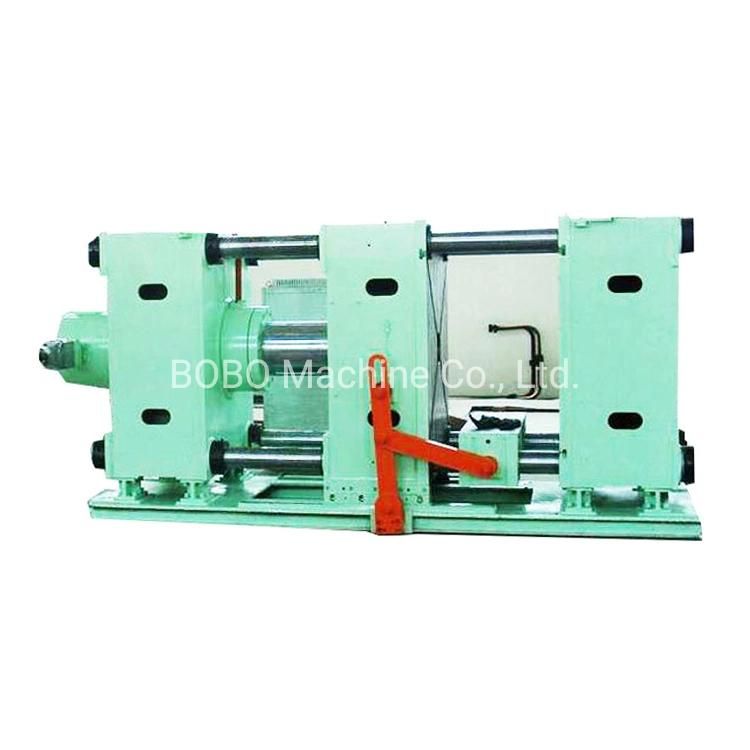

The dynamic table serpentine bender for air-conditioning system is the special equipment of forming refrigerators, freezers condenser, and evaporator tubes. It can bend copper tubes, Bundy tubes, aluminum tubes etc Φ10 below different specifications of thin-walled tubes.

This machine adopts advanced PLC control, can adjust bending radius, bending angle, bending times within a certain range. All the bending procedures are automatically, and equipped with manual operation function. Feeding and bending all use pneumatic.

Rotary table synchronized with bend head, so the ability to control larger serpentine coils becomes much easier.

1. Rolling diameter: 22.5-38"

2. Rolling width: 7.5-20"

3. Rolling thickness: 6mm [20" rim]

4. PLC control from GM, USA.

5. Button from Germany

6. Air switch and contactor from GM, USA.

7. Photoelectricity switch from Germany.

8. Productivity: 100-200 pics/hour

9. Power: 18.5kw