Gantry Type Plasma Cutting Machine

Jinan Huaxia Machinery Equipment Co., Ltd.- Certification:CE, ISO 9001:2008

- Condition:New

- Control:Automatic

- Application:Metal

- Connected Shaft Number:2-Shaft

- Style:Gantry

Base Info

- Model NO.:HX4080

- Type:CNC

- Power Supply:USA Hyperrtherrm ,China Huayuan

- Control System:Startfire,Flmc-F2300b

- Nesting Software:Fastcam

- Design Software:Auto CAD,Caxa

- File Transfer Mode:USB Interface

- Input Voltage:3phase, 380V

- Automatic Torch Height Controller:China Hyd

- Transport Package:Plywood Case After Packed by Wrapping Film

- Specification:3000*8000mm

- Trademark:HuaXia

- Origin:China

- HS Code:8456401000

- Production Capacity:150 Sets,Month

Description

Basic Info.

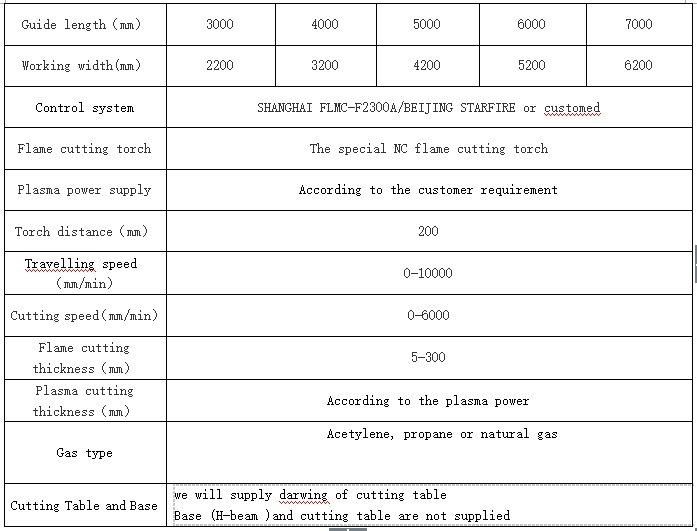

Model NO. HX4080 Type CNC Power Supply USA Hyperrtherrm /China Huayuan Control System Startfire/Flmc-F2300b Nesting Software Fastcam Design Software Auto CAD/Caxa File Transfer Mode USB Interface Input Voltage 3phase, 380V Automatic Torch Height Controller China Hyd Transport Package Plywood Case After Packed by Wrapping Film Specification 3000*8000mm Trademark HuaXia Origin China HS Code 8456401000 Production Capacity 150 Sets/MonthProduct Description

gantry cnc plasma cutting machine for metal

1, the gantry type CNC cutting machine can equip with different plasma flame more cutting torch according to customer different configuration.

2, CNC flame / plasma cutting machine is a kind of high efficiency, energy saving cutting equipment. Precision cutting work is suitable for all kinds of thickness of carbon steel, stainless steel and non-ferrous metal plate blanking, improving utilization of material, saving time and material . CNC flame cutting machine can max cut 5 - 300mm thickness with of high quality for carbon steel material.

3, gantry type beam, it's bearing capacity is good, suitable for wide span, effective bilateral drive, compact structure, whole temper, sufficient to eliminate welding stress, stable and reliable performance.

4, the X axis guide rail with domestic or imported linear guide rail, high precision, good guide. The Y axis guide rail adopts traits, the surface by grinding processing, has the very high mechanical precision and wear resistance.

5, the driving rack , gear by the professional manufacturer of custom, it's surface carburizing and quenching, high precision. The X and Y axis transmission adopts Germany NEUGART high precision, high torque, low backlash, maintenance free planetary gear reducer.

6, the drive system can choose servo drive or stepping driving, according to the requirement of customers can choose the world's top brand from Japan -- Panasonic AC servo or stepper motor drive, can be more stable running speed, a wider range of speed transmission, short acceleration time;

7, lower body is made of aluminum alloy structure, lifting guide adopts the linear guide rail with ball screw lifting;

8,Automatic programming system is simple and easy to use.

9, control system adopts currently the most excellent stability and strong anti-interference ability.

10, multi configuration cutting usage, the cutting tool by configuring different, different cutting torch system can meet all kinds of fire, powder spraying, plasma processing applications.

11, the system is divided into gas control panel and the gas path distribution system, production of professional manufacturers. Equipped with automatic ignition device, a backfire preventing device, safety and stability.

12, according to the requirements can be equipped with various kinds of imported or domestic plasma cutting, for different metal materials.

13, add other special function according to special requirement