Wall Panel Cold Roll Forming Machine China High Quality

Hangzhou Santiway International Co., Ltd.- Condition:New

- Certification:ISO 9001:2000, CE

- Automation:Automatic

- Material Grade:Q215,Q235,Q345,Q550

- Material Thickness:0.14mm to 2mm

- Forming Speed:16~20m,Min or According to Customer′s Requirment

Base Info

- Model NO.:panel forming machine

- Profile Size:Can Design Accoridng to Your Sample or Drawings

- Drive Way:Chain or Gear Box

- Delivery Time:30 Days Finished and 10 Days More to Test

- Operating:One Experienced Person Is Enough

- Size:Depends on Final Design

- transportation:by Sea or Train

- Transport Package:Machine in 40′′gp,Other Accessories in Wooden Case

- Specification:CE

- Trademark:STW

- Origin:China

- HS Code:84552210

- Production Capacity:10sets,Month

Description

Basic Info.

Model NO. panel forming machine Profile Size Can Design Accoridng to Your Sample or Drawings Drive Way Chain or Gear Box Delivery Time 30 Days Finished and 10 Days More to Test Operating One Experienced Person Is Enough Size Depends on Final Design transportation by Sea or Train Transport Package Machine in 40′′gp,Other Accessories in Wooden Case Specification CE Trademark STW Origin China HS Code 84552210 Production Capacity 10sets/MonthProduct Description

| Machine's Components: | Uncoiler, coil sheet guiding device, film covered device(optional), main roll forming system, cutting device, hydraulic, PLC control table and final product run out table. |

| Specification: | -Suitable raw material: color steel sheet; galvanized steel sheet; -Suitable thickness of raw material: 0.3-0.8mm; -Main motor power: 5.5kw(depend on finaldesign); -Hydraulic station power: 2.2kw(depend on final design); -Forming speed: about 15m-20m/min -Uncoiler's loading capacity: 5tons(can be increased to 10 tons or at buyer's requirement); -Control system: Mitsubishi PLC&converter; -Voltage:380V, 3phase, 60HZ, or at buyer's requirement; Machine's dimension: about 8m-1.5m*1.4m(depend on final design); |

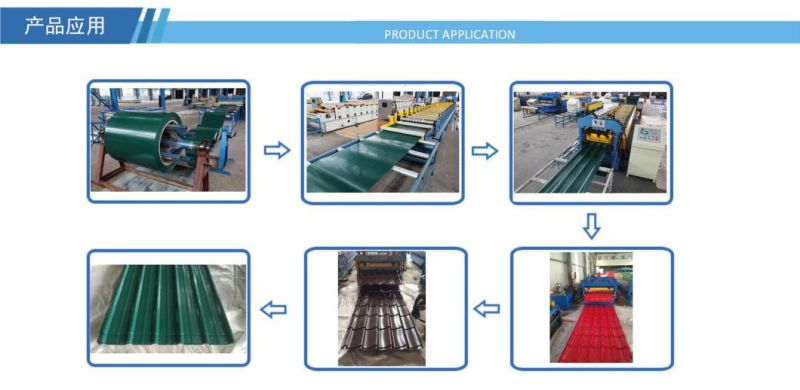

| Working flow: | Uncoiling the steel coil→ feeding and guiding the steel sheet→ film covering→ main roll forming→ cutting the panel→fianl product run out the table |