CE Certificate Nc Pipe Bending Machine Semi Automatic Hydraulic Pipe Bending Machine (GM-SB-89NCB)

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

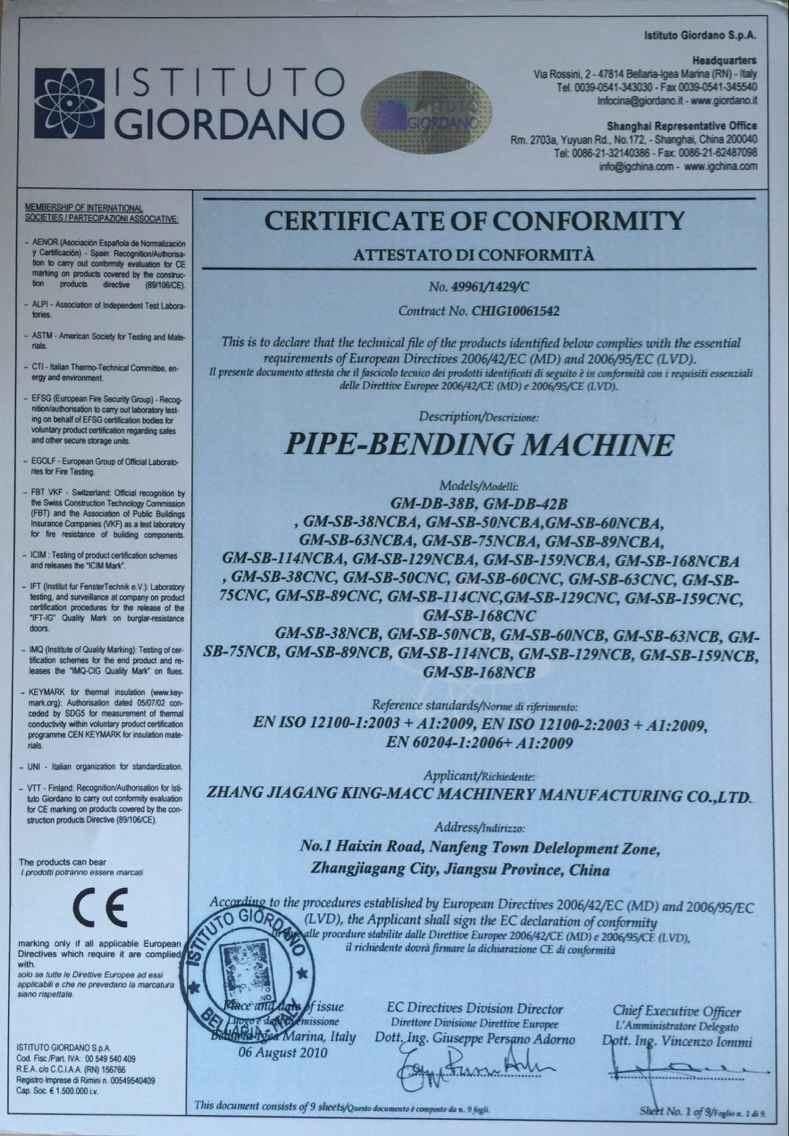

- Certification:ISO 9001:2000, CE

- Automation:Semi-Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:GM-SB-89NCB

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S, M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Bending Drive:Hydraulic

- Technical:Cold Bend

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. GM-SB-89NCB Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S, M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Bending Drive Hydraulic Technical Cold Bend Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000 Production Capacity 5000PCS/YearProduct Description

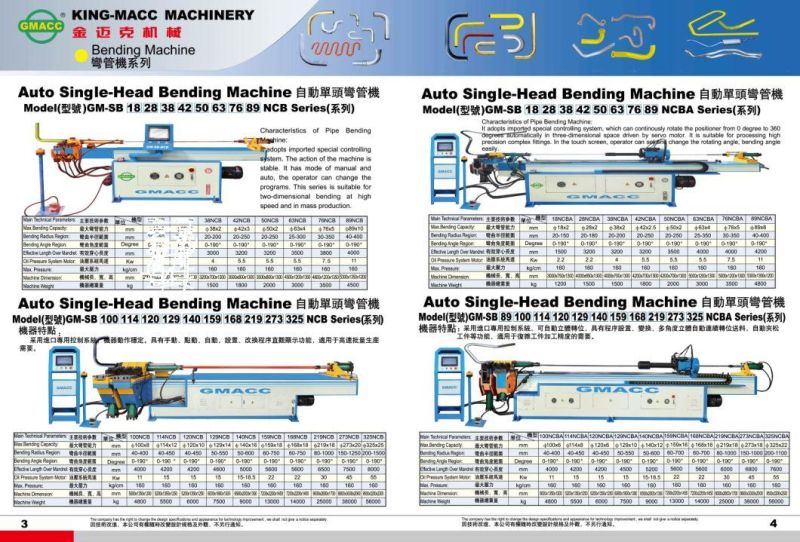

Technical Parameter and Configuration for Automatic Pipe Bending Machine GM-SB-89NCB- Machine Characteristic

- Main Technical Parameter

| Name | Unit | Parameter |

| Max. Bending Capacity | mm | ¢89*10 |

| Bending Radius Range | mm | 40-400 |

| Max. Bending Angle | ° | 190° |

| Though Effective Distance | mm | 4000 |

| Bending Speed | °/sec | 25 |

| Bending Precision | ° | ±0.10 |

| System Motor Power | KW | 11 |

| Oil Pump Delivery Volume | L | 30 |

| Max. Pressure | Mpa | 16 |

| L*W*H (Packaging Dimension) | mm | 5300*1350*1200 |

| Machine Weight | T | 4.8 |

- Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Siemens Beide or Suzhou Runmali |

| Hydraulic Valve | Yuci Yuken |

| Over Flow Valve | Yuci Yuken |

| Encoder | Japan Nemicon |

| Hydraulic Pump | Wuxi Tuoli |

| Sealing Element | Shanghai Qifan |

| Contactor | Schneider |

| Over-Thermal Relay | Schneider |

| Proximity Switch | Omron |

| Power Switch | Taiwan Mingwei |

| Tansformer | Wuxi Xingyu |

| Oil Tube | Zhejiang Tongxin |

| Touch screen | Taiwan Weinview |

| PLC | Japan Mitsubishi |

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer.We are focusing on metal pipe/tube processing machinery.

2. Q: How to choose the pipe/tube bending machines?

A: You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

3. Q: What certificate do you have?

A: We have both ISO and CE certificate.

4. Q: Where is your factory located?

A: Our factory is located in Zhangjiagang City, Jiangsu Province, about 2 hours to Shanghai by car. You can fly to

Shanghai Hongqiao or Pudong airport directly.Or you can take fast train to Zhangjiagang railway station.

Contact Person: Mr. Ronaldo Chen

Video link in Youtube for King-Macc machinery:

https://king-macc.en.made-in-china.com

www.gmacc.ru

Website: king-macc.en.made-in-china.com http://king-macc.en.made-in-china.com http://king-macc.en.made-in-china.com