Bedding Blanket / Quilt / Ice Silk Mattress Round Knife Cutting Machine

Jinan Zhuoxing Intelligent Technology Co., Ltd.- Waterproof Rating:IPX-1

- Warranty:1-year

- Certification:CE, SGS, ISO 9001:2015

- Condition:New

- Control:Automatic

- Application:Paper, Leather, Fabric, PVC, Other Composite Fabrics

Base Info

- Model NO.:ZX-1625V

- Power Source:Electric

- Layout:Horizontal

- Working Area:2500*1600mm (L*W)

- Cutting Thickness:0.1-25.0mm(Depend on The Material)

- Cutting Precision:0.1mm

- Working Voltage:AC 110V,220V,380V, 50Hz

- Rated Power:11kw

- Max Cutting Speed:1200mm,S

- Safety Device:Infrared Sensors, 4 Emergency Stop Bottons

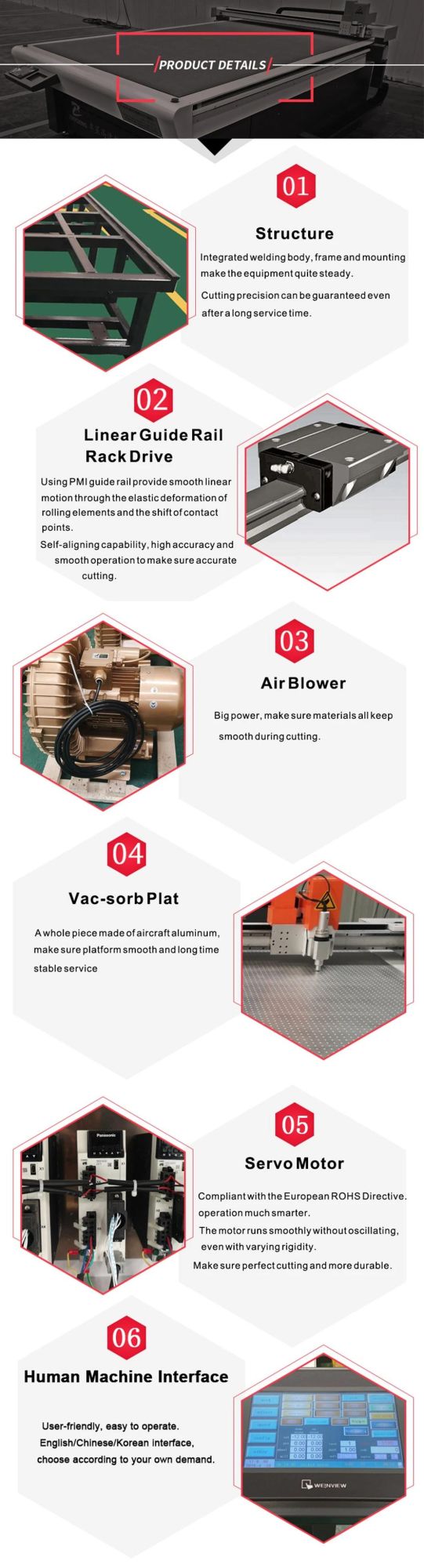

- Drive System:Panasonic Servo Motor, PMI Linear Guideway

- Fixed Type:Intelligent Vacuum Adsorption

- Multifunctional Head:Wheel Knife Tool Tool, V-Cut Tools, Universal Cutt

- Transmission Interface:Ethernet

- Fixed Mode:Vacuum Absorb

- Operation Properties:Online , Offline Operation; Continuous Cutting Wit

- Transport Package:Wooden Case

- Specification:3.43*2.50*1.40m (L*W*H)

- Trademark:ZX

- Origin:Shandong, China

- Production Capacity:500 Sets,Month

Description

Detail:

Table: A single piece of aluminium honeycomb plate, more stable and druable.

Fix: The whole plate divides into 8 adsorption areas, more effectivity.

Drive: Use rack instead of belt, more stable and durable.

Vibrating knife: Cut quickly and smoothly, max cutting speed 1200mm/s, cut quick and meanwhile ensure its precision.

Automatic feeding: With conveyor, realize 24 hours working.

Scanner: If you want cut some new models but don't have pattern, use this.

Package and transportation

Our advantage and servise

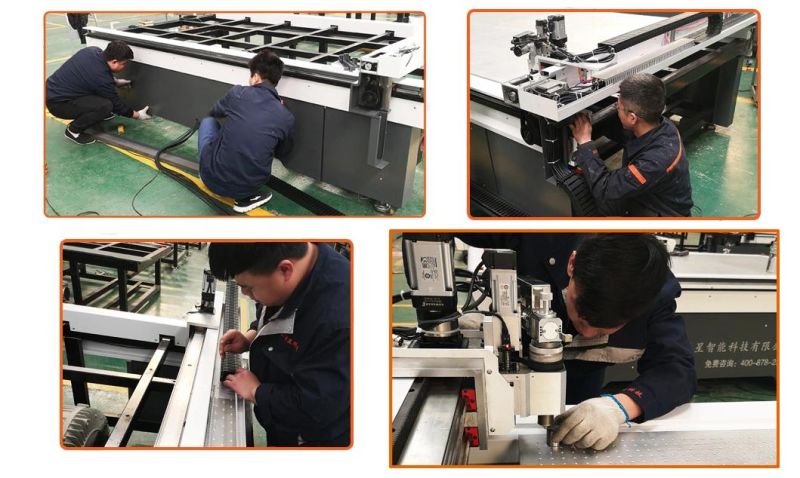

1. We are manufacturer, so we accept customization and support machine design for your particular request for different purpose or material and etc.

2. We have professional rich-experience technicians, they can help when you need any technological support.

3. Self-development knife tools and purpose made high quality blades realize perfect cutting, and more durable.

4. With our patented correction system, cutting more exact.

5. We promise to use the best quality components, also support customization.

6. A free operation training in our factory, welcome to visit, and if you don't have enough time, we will send you a training video.

7. One year guarantee, and life-time technological guidance.

8. Consumables(like blade, table cover) always supply at cost price.

9. Any output format is DXF or PLT can be recognized.

10. Welcome to send us materials, we will finish cut and show you the result.

Company profile

Jinan Zhuoxing Intelligent Technology Co. Ltd is a high-tech enterprise which is specialized in research and development, production, sales and service of CNC knife cutting equipment and related CAD/CAM software system.

Zhuoxing supply an automated, computerized cutting systems cut with accuracy and repeatability and have been engineered for single, low-ply cutting requirements.

Precision cutting tools offer the utmost flexibility for hundreds of soft and some hard-to-cut material applications in various industries, such as Garment; Shoes & Accessories; Gasket; Packaging; Advertising; Home furnishing; Automotive Interiors; Arts & Crafts; Toys; Sporting goods; Camping & Outdoor gear, etc.

Zhuoxing supply the ideal solution for prototyping, short-run production and full production runs, tackling down challenges of customization and fast delivery.

We have had great success in China, and will be powered by innovation and uncompromising standards in the future.

Some info please share with us for supply a suitbale machine for you

1. which kinds of materials are going to cut?

2. what's the largest size of original material?

3. what's the thinkness of the material?

4. what's the smallest diameter during cutting?

5. except for cutting, do you need more functions?

6. what's the expected production efficiency?