CT Od Mounted Pipe Facing Machine

Watt Machinery Technology Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:1-year

- Certification:CE, ISO 9001:2000, ISO 9001:2008

- Condition:New

- Control:Automatic

- Application:Metal, Plastic

Base Info

- Model NO.:CT

- Power Source:Electric

- Cutting Model:Blade Cutting

- Beveling Angle:0,30,37.5 Degree

- Motor Brand:Electric

- Beveling Type:Cold

- Transport Package:Tool Box

- Trademark:Watt

- Origin:China

- HS Code:846190

- Production Capacity:500

Description

Model

PFM-1.0

PFM-1.0A

PFM-4.0A

Drive

Battery

Electric motor

Electric motor

Range

Φ3-25.4mm

Φ3-25.4mm

Φ12.7-110mm

Tool stroke

5mm

5mm

5mm

thickness

0.5-3mm

0.5-3mm

0.5-5mm

No-load rotating

300rpm

300rpm

300rpm

Voltage

14.4v

220v

220v

Power

-

1.3kw

1.3kw

Net Weight

2.3kg

4.8kg

19kg

Standard with four diameter clamping block, more specifications please inquire

Above parameters just for reference only, not acceptance criteria

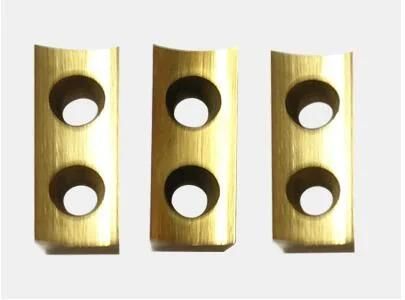

TOOLING

2pcs facing tool

Material:Cermet or Carbide

Beveling tool optional

Before you place order to us, please let us know the following information:

- Choose the right ModelConfirm the beveling angel required

- Confirm the welding joint required (U, V, Double V or Compound preparation)

- Advise your pipe material ( Carbon steel, stainless steel or others)

- Other special demands about machine

- The spare parts needed

1. Measure the size of the pipe to be machined, select the swelling block according to the swelling block diagram, install it on the wedge block, tighten the bolt, make sure it is secure and loose.

2. According to the processing requirements, select the tool table in the appropriate angle of the tool, installed in the machine cutter, tighten the bolt, fixed tool.

3. Rotate the feed hand wheel to extend the feed spindle.

4. Make the machine tightening mechanism into the tube, the cutter head and pipe surface should be left enough feed space.

5. Rotate the hand wheel and adjust the machine position to ensure that the machine feeds the spindle coaxial with the center of the tube. Tighten the nut on the hand wheel with a wrench.

6. Start the motor, rotate the feed handwheel, the blade is in contact with the pipe wall, and groove.

7. After finishing the machining, first exit the tool, then release the tightening mechanism, remove the machine from the tube.