Ak150 Aluminum Alloy Frame Bending Machine

Shandong Drivecnc Intelligent Equipment Co., Ltd.- After-sales Service:One Year

- Waterproof Rating:IPX-0

- Warranty:1-year

- Condition:New

- Certification:CE

- Automation:Automatic

Base Info

- Model NO.:AK150

- Suitable for:Aluminum, Alloy, Stainless Steel

- Type:Cnc Bending Machine

- Weight:450kg

- Size:L1302*W780*H1360mm

- Transport Package:Wooden Case

- Specification:1.4m3

- Trademark:DRIVECNC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000

Description

Basic Info.

Model NO. AK150 Suitable for Aluminum, Alloy, Stainless Steel Type Cnc Bending Machine Weight 450kg Size L1302*W780*H1360mm Transport Package Wooden Case Specification 1.4m3 Trademark DRIVECNC Origin China HS Code 8462219000 Production Capacity 5000Product Description

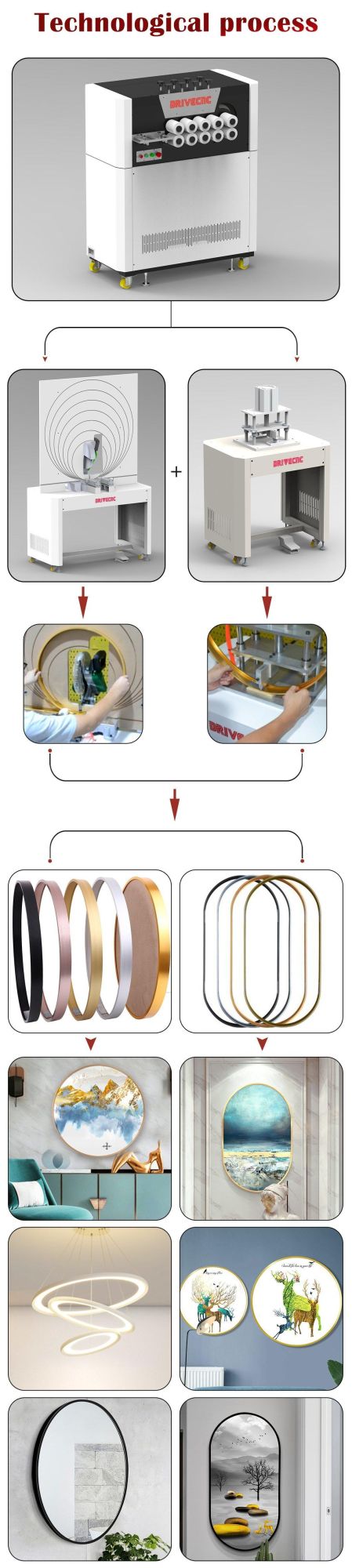

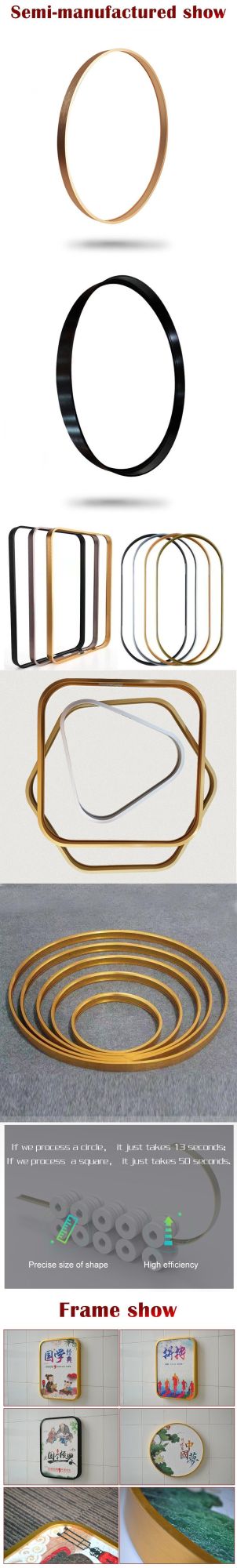

AK150 Automatic Rounding Bending Machine Part 1. Machine DescribeAutomatic Rounding Bending Machine is used to bend aluminum alloy sections ,it can process many types of shape,for example,Circle,ellipse,runway circle,polygon and irregular figure,machine is controlled by computer,humanized software has more practical function for customer. According to different shapes,machine will process follow the shape,machine software is easy to learn and operate,it is convenient,it is used to process Frame,mirror frame,Decorative picture,Ceiling,lamps and lanterns,Advertising,Furniture and metal forming industry.

Part 1. Machine DescribeAutomatic Rounding Bending Machine is used to bend aluminum alloy sections ,it can process many types of shape,for example,Circle,ellipse,runway circle,polygon and irregular figure,machine is controlled by computer,humanized software has more practical function for customer. According to different shapes,machine will process follow the shape,machine software is easy to learn and operate,it is convenient,it is used to process Frame,mirror frame,Decorative picture,Ceiling,lamps and lanterns,Advertising,Furniture and metal forming industry.Part 2. Machine Introduction

Automatic Rounding Bending Machine including material support frame /feed structure/bending structure/machine shell.

1.Material support frame and side baffle,this structure will help us to feed material in machine more better ,including three pcs support axis and two sets side baffle bearing,we can adjust the position of side baffle bearing follow different material width.

2.Feed structure is used to control the feeding precision follow the size of shape.Including four sets of feed axis,drive part,pressure adjustment structure.Four sets of feed axis,all of them are connected with servo motor by toothed gear,depends on different thickness material,we can adjust the pressure by hand wheel pressure adjustment structure.there are many different types of material,so we need to get the material sample and change the size of groove follow the cross section of material.

3.Bending structure will bend aluminum alloy sections follow different curve shapes.Servo motor provide enough power to bend material,when machine is working,servo motor will turn to suitable angle,then machine will start to bend the curve of shape.

4.Outside metal shell will protect main body of machine.Machine is made of square tube welding framework with pulley,machine can be moved and located,the main body of machine is made of 20mm carbon steel,it is processed by CNC machining center,it will make sure that the drive part is enough good about precision and rigidity,it make machine get high efficiency stable performance and long service life.

Part 3. Technical Specification

| Feed Speed | 150mm/s |

| Feed Accuracy | ±0.2mm |

| Bend Axis Torque | 200N·M |

| Die Axis Length | 120mm |

| Minimum Bend radius | 50mm |

| Control System | Autodrive Automatic bending system |

| Machine Size | L1302mm*W780mm*H1650mm |

| Power | 1.5KW |

| Voltage | 220V AC |

| Weight | 450Kg |

| Shape | Circle,ellipse,runway circle,polygon and irregular figure |

| Material | Aluminum profile,Stainless steel |

| Industry Application | Frame,mirror frame,Decorative picture,Ceiling,lamps and lanterns,Advertising,Furniture and metal forming industry |

Part 4. Machine Detail Introduction