High Quality Hydraulic Pipe Bending Machinewith Wiper Die

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Condition:New

- Certification:ISO 9001:2000, CE, UL

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

Base Info

- Model NO.:38CNC-4A-2SV

- Type:Pipe and Tube Bending Machine

- Certificate:ISO9001: 2000

- Applicable Material:S. S., M. S., Copper, Aluminium, Alloy, Galvanized

- Applicable Shape:Round, Rectangle, Square, Oval, Solid Bar, Profile

- Application:Wheelbarrow, Wheelchair, Boiler, Automobile

- Transport Package:Iron Frame,Wooden Case

- Specification:CE

- Trademark:GMACC

- Origin:China

- HS Code:8462219000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. 38CNC-4A-2SV Type Pipe and Tube Bending Machine Certificate ISO9001: 2000 Applicable Material S. S., M. S., Copper, Aluminium, Alloy, Galvanized Applicable Shape Round, Rectangle, Square, Oval, Solid Bar, Profile Application Wheelbarrow, Wheelchair, Boiler, Automobile Transport Package Iron Frame/Wooden Case Specification CE Trademark GMACC Origin China HS Code 8462219000 Production Capacity 5000PCS/YearProduct Description

GM-SB-38CNC Full-Auto Numerical Control- Machine Characteristics

| Name | Unit | Parameter |

| Max. Bending Capacity | mm | 38*2 |

| Max.push bending capacity | mm | 28*2 |

| Max.bending radius of drawbending | mm | 20-200 |

| Max.bending radius of push bending | mm | 6D~∞ |

| R tolerance between two mould | mm | 50 |

| Effective length over mandrel | mm | 3200 |

| Max. Bending Angle | ° | 190 |

| Bending Speed | °/sec | 120 |

| Turning Speed | °/sec | 200 |

| Feeding Speed | mm/sec | 800 |

| Bending Precision | ° | ±0.10 |

| Turning Precision | ° | ±0.10 |

| Feeding Precision | mm | ±0.10 |

| Turning Servomotor Power | kW | 0.4 |

| Benging servomotor power | kW | 3.5 |

| Feeding Servomotor Power | kW | 1.5 |

| Moving mould servomotor power | kW | 0.75 |

| Max. Pressure | Mpa | 16 |

| L*W*H (Packaging Dimension) | mm | 4200*700*1300 |

| Weight | T | About 2.2 |

- Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens(Beide)/ Runmali |

| Hydraulic Pump | Wuxi Tuoli |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Taiwan Shanghong (Imported) |

| Cylinder | Shanghai Qifan |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Servo Motor | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Switch power | Taiwan Mingwei |

| Transformer | Wuxi Xinyu |

Tooling Samples

Bending Die Clamp Die Pressure Die

Mandrel Wiper Die(optional)

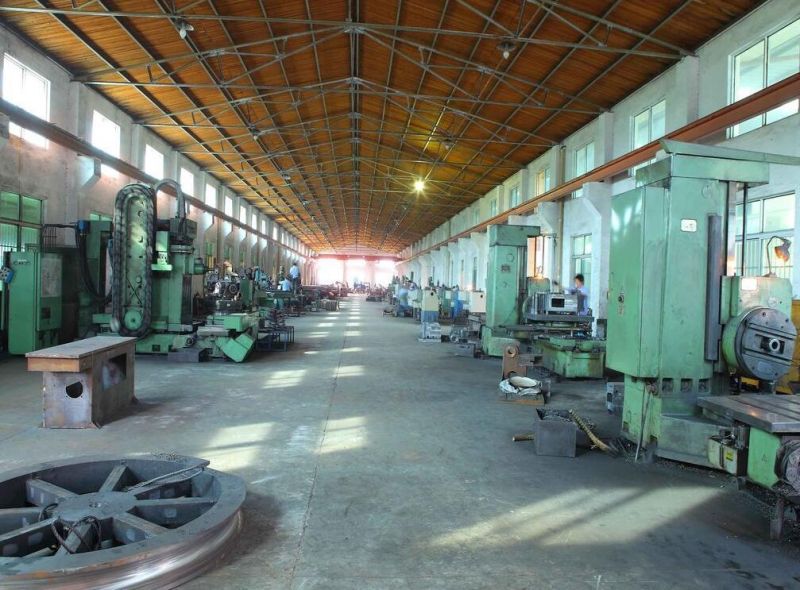

Company Photos