QC11Y-12X2500 Hydraulic Guillotine Shearing Machine, Steel Plate Shearing and Cutting Machine, Hydraulic Guillotine Type Shearing Machine

Shaanxi HAVEN Equipment Co., Ltd.- Condition:New

- Certification:ISO 9001:2008

- Automation:Semi-Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel

- Blade Clearance Adjusted by Hydraulic:Cutting Angle Adjusted by Motor

- Transport Package:Steel Pallet

Base Info

- Model NO.:QC11Y-12x2500

- Specification:Thickness:12mm, Length: 2500mm

- Trademark:HAVEN

- Origin:China

- HS Code:8459

- Production Capacity:30 Units,Month

Description

Basic Info.

Model NO. QC11Y-12x2500 Specification Thickness:12mm, Length: 2500mm Trademark HAVEN Origin China HS Code 8459 Production Capacity 30 Units/MonthProduct Description

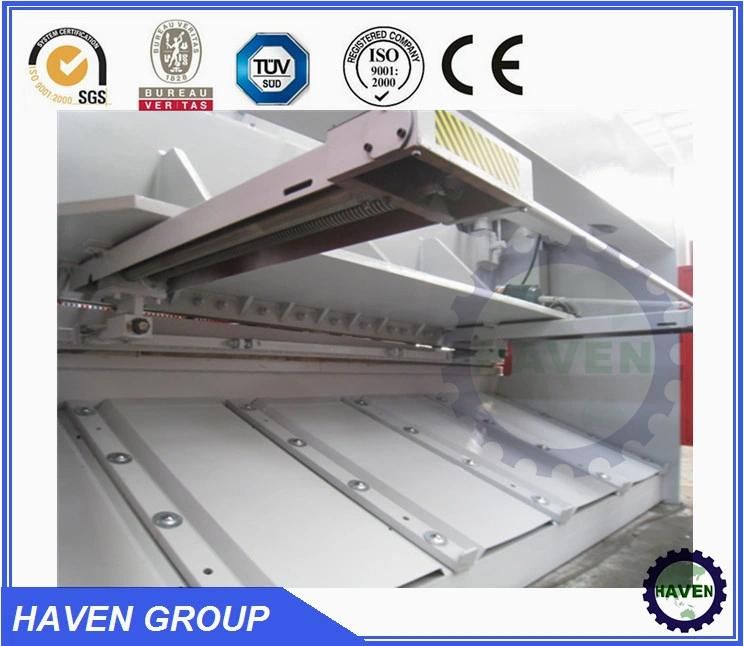

QC11Y-12X2500 Hydraulic Guillotine Shearing Machine

1.Standard Facilities:

* Hydraulic gear pump China famous brand

* Main Electric Components Are From SIEMENS Brand

* Hydraulic valve is from USA brand HUADE

* Hydraulic Seal Rings Are From NOK, Japan

* E21S Control Panel 1 Set

* Electrical Control Box 1 Set

* Motorized Back Gauge 1 Set

* Pedal Control Switch 1 Set

* Standard Blade 1 Set

* Fundation Bolts 4 Pcs

* English Manual 1 Set

* Roller On Front Table 1 Set

* Front Support Arm With Stopped 1 Set

2. Estun E21 NC Press Brake Control system:

1. Monochrome LCD Box Panel.

2. Integral factor programmable freely

3. Automatic positioning control

5.Internal time relay

6.Ram stroke counter

3. Our Services

1: Response in time after getting customer's claim

1: Provide solution in 1 day

2: Usually solve problem within 2 days

2. For big machine, Installation Service is available as per customer's requirement

4. Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments.

6. Main functions:

1. The machine frame is welded construction with steel plate, and stress is eliminated by vibration. with high strength, stable performance, easy operation and convenient maintenance.

2. As the cutting beam of machine has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

3. With the help of hydraulic drive, swing beam, return of knife beam is smooth and prompt by accumulator ( Nitrogen cylinder ).

4. Stepless adjusting is available for the stroke of knife beam for different length plate shearing.

5. The position of low blade is adjustable, thus ensuring the equilibrium of the gap between blades after regrinding.

6. It is easy and quick to adjust the gap between blades. The value of the gap is indicated on a dial.

7. Motorized adjusting and manual adjusting for the back gauge.

Main specification:

| Model | Mild Steel (450MPA) | Cutting Length(mm) | Depth Of Throat(mm) | Back Gauge Range(mm) | Rake Angle Adjustment | Strokes Per Minute | Main Motor | L× W× H(mm) | Weight(t) |

| 4× 2000 | 4 | 2000 | 80 | 750 | 0.5° -2° | 14 | 5.5 | 2600× 1680× 1750 | 3.8 |

| 4× 2500 | 4 | 2000 | 80 | 750 | 0.5° -2° | 14 | 5.5 | 3125× 1750× 1765 | 4.5 |

| 6× 2500 | 6 | 2500 | 80 | 750 | 0.5° -1° 30′ | 14 | 7.5 | 3100× 1725× 1900 | 5.3 |

| 6× 3200 | 6 | 3200 | 80 | 750 | 0.5° -1° 30′ | 12 | 7.5 | 3935× 1840× 1995 | 6.5 |

| 6× 4000 | 6 | 4000 | 80 | 750 | 0.5° -1° 30′ | 10 | 7.5 | 4650× 1840× 2100 | 8.5 |

| 6× 5000 | 6 | 5000 | 80 | 750 | 0.5° -1° 30′ | 8 | 7.5 | 5650× 2050× 2400 | 10.5 |

| 6× 6000 | 6 | 6000 | 80 | 750 | 0.5° -1° 30′ | 8 | 7.5 | 6650× 1980× 2380 | 15.2 |

| 8× 2500 | 8 | 6000 | 80 | 750 | 0.5° -1° 30′ | 14 | 7.5 | 3135× 1840× 2075 | 6 |

| 8× 3200 | 8 | 3200 | 80 | 750 | 0.5° -1° 30′ | 12 | 7.5 | 3850× 1990× 2050 | 6.8 |

| 8× 4000 | 8 | 4000 | 80 | 750 | 0.5° -1° 30′ | 10 | 7.5 | 4650× 1890× 2075 | 9 |

| 8× 5000 | 8 | 5000 | 80 | 750 | 0.5° -2° | 7 | 15 | 5650× 2050× 2400 | 12.5 |

| 8× 6000 | 8 | 6000 | 100 | 750 | 0.5° -2° | 7 | 15 | 6805× 2115× 2715 | 19.8 |

| 10× 2500 | 10 | 2500 | 100 | 750 | 0.5° -2° 30′ | 10 | 15 | 3195× 1915× 2205 | 8 |

| 10× 3200 | 10 | 3200 | 100 | 750 | 0.5° -2° 30′ | 8 | 15 | 3895× 1900× 2235 | 8.8 |

| 10× 4000 | 10 | 4000 | 100 | 750 | 0.5° -2° 30′ | 6 | 15 | 4695× 1970× 2270 | 9.15 |

| 10× 5000 | 10 | 5000 | 100 | 750 | 0.5° -2° 30′ | 5 | 15 | 5700× 2115× 2715 | 16 |

| 10× 6000 | 10 | 6000 | 100 | 750 | 0.5° -2° 30′ | 5 | 15 | 6905× 2115× 2800 | 22 |

| 12× 2500 | 12 | 2500 | 100 | 750 | 0.5° -2° 30′ | 10 | 15 | 3195× 2000× 2210 | 8.3 |

| 12× 3200 | 12 | 3200 | 100 | 750 | 0.5° -2° 30′ | 8 | 15 | 3895× 1950× 2240 | 9.2 |

| 12× 4000 | 12 | 4000 | 100 | 750 | 0.5° -2° 30′ | 5 | 15 | 4710× 1950× 2450 | 13 |

| 12× 5000 | 12 | 5000 | 100 | 750 | 0.5° -2° 30′ | 5 | 18.5 | 5750× 2115× 2800 | 20 |

| 12× 6000 | 12 | 6000 | 100 | 750 | 0.5° -2° 30′ | 5 | 18.5 | 7150× 2300× 3100 | 29 |

| 16× 2500 | 16 | 2500 | 100 | 750 | 0.5° -2° 30′ | 8 | 15 | 3215× 1970× 2340 | 8.7 |

| 16× 3200 | 16 | 3200 | 100 | 750 | 0.5° -2° 30′ | 7 | 15 | 3915× 1970× 2455 | 11 |

| 16× 4000 | 16 | 4000 | 100 | 750 | 0.5° -2° 30′ | 6 | 15 | 4715× 2010× 2590 | 15 |

| 16× 5000 | 16 | 5000 | 100 | 750 | 0.5° -3° | 5 | 22 | 6000× 2300× 3000 | 23 |

| 16× 6000 | 16 | 6000 | 80 | 750 | 0.5° -3° | 5 | 37 | 7250× 2400× 3100 | 36 |

| 20× 2500 | 20 | 2500 | 100 | 750 | 0.5° -3° | 6 | 22 | 3235× 2020× 2465 | 10.5 |

| 20× 3200 | 20 | 3200 | 120 | 750 | 0.5° -3° | 5 | 30 | 4150× 2065× 2755 | 18 |

| 20× 4000 | 20 | 4000 | 120 | 750 | 0.5° -3° | 4 | 30 | 4955× 2125× 2885 | 21 |

| 20× 5000 | 20 | 5000 | 120 | 750 | 0.5° -3° | 4 | 37 | 6000× 2300× 3050 | 29 |

| 25× 2500 | 25 | 2500 | 120 | 750 | 0.5° -3.5° | 5 | 37 | 3465× 2130× 2710 | 15 |

| 25× 3200 | 25 | 3200 | 120 | 750 | 0.5° -3.5° | 5 | 37 | 4120× 2200× 3000 | 21 |

| 25× 4000 | 25 | 4000 | 120 | 750 | 0.5° -3.5° | 4 | 37 | 4950× 2200× 3150 | 26 |

| 30× 2500 | 30 | 2500 | 120 | 750 | 0.5° -3.5° | 4 | 37 | 3465× 2170× 2770 | 16 |

| 30× 3200 | 30 | 3200 | 120 | 750 | 1° -3.5° | 3 | 37 | 4200× 2300× 3200 | 23 |