1/4 Stainless Steel Plate Bender Machine

LZK CNC Machine Tool (Anhui) Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

Base Info

- Model NO.:EPB-130T3200

- Condition:New

- Certification:ISO 9001:2000, CE

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel, Mild Steel, Galvanized Sheet

- Type:Press Brake

- CNC System:Esa S640

- Axes:Y1, Y2, X, R, Z1, Z2

- Max Bending Length:3200mm

- Max Bending Thickness:5mm for 3m Sheet

- Weight:9500kg

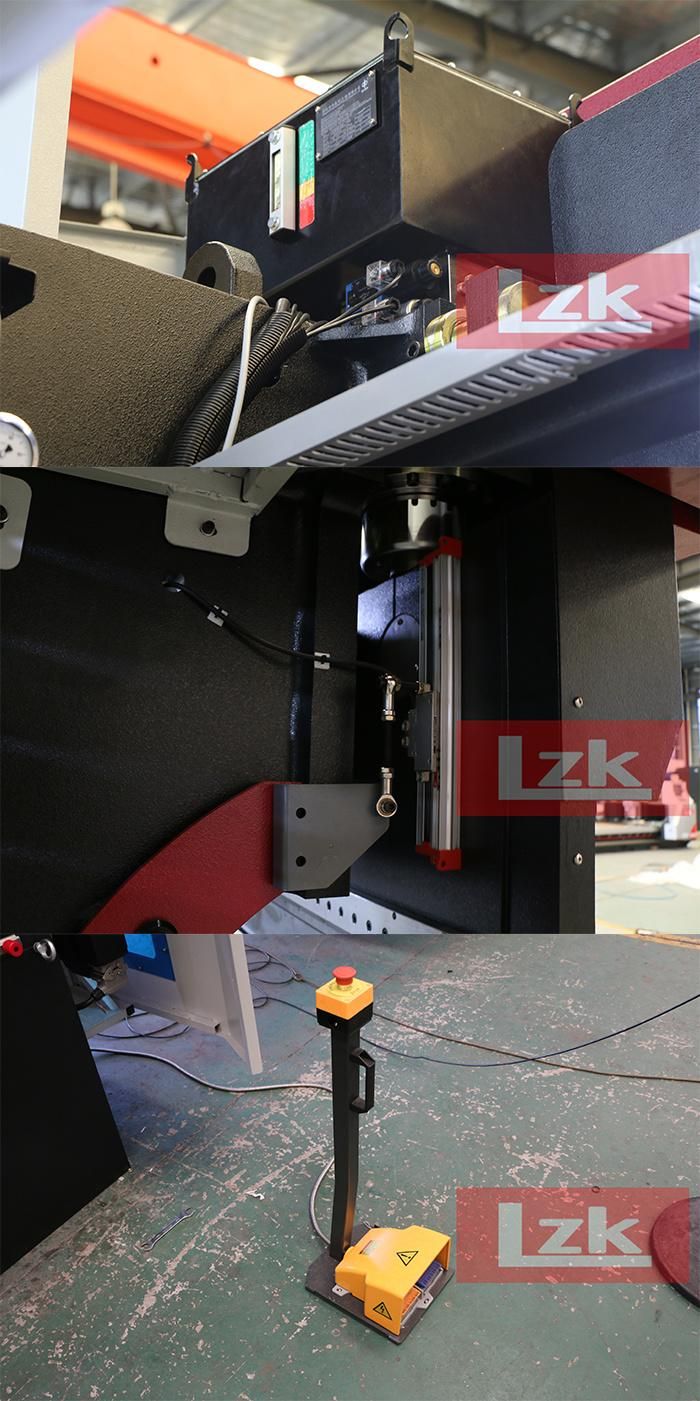

- Backgauge:600mm Distance, Ball Screw and Linear Guide Rail

- Main Motor:Servo Motor

- Main Motor Power:5.7kwx2

- Main Electrical Components:Schneider

- Hydraulic System:Bosch-Rexroth

- Clamping System:Wila Hydraulic Clamping System

- Grating Ruler:Italy Givi

- Transport Package:20gp

- Specification:3850× 1850× 2600mm

- Trademark:LZK

- Origin:China

- HS Code:8462219000

- Production Capacity:100 Sets,Month

- Package size per unit product:4100.00cm * 1700.00cm * 2000.00cm

- Gross weight per unit product:6500.000kg

Description

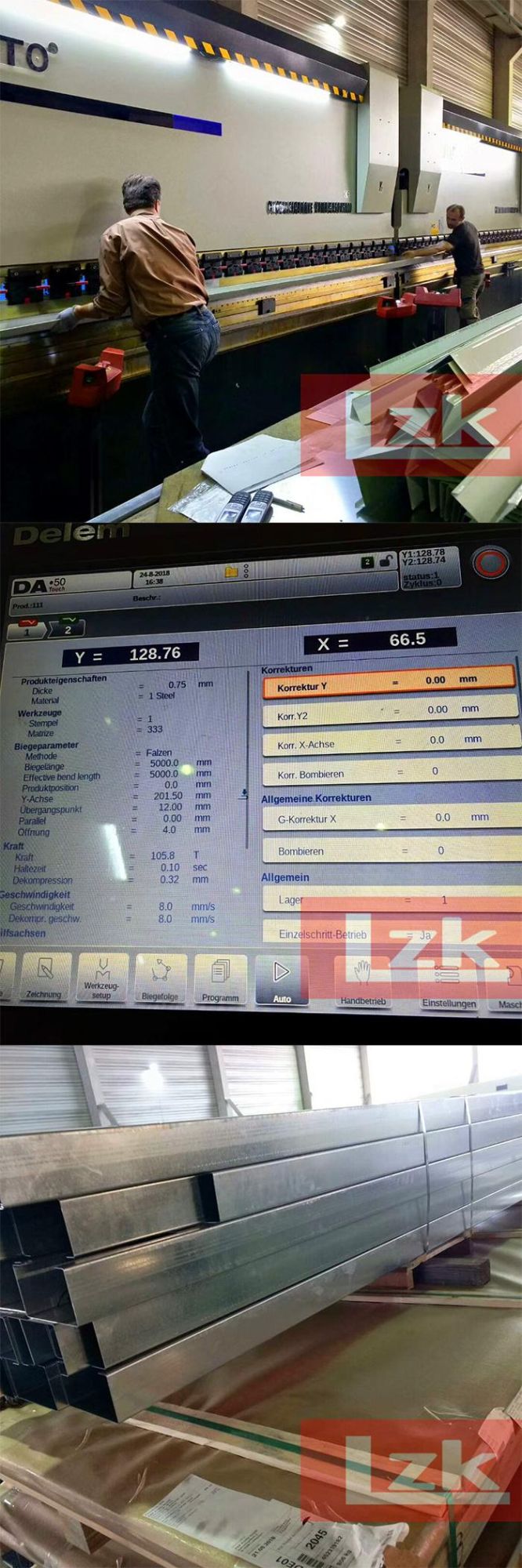

--Because of their high speed and high precision, they are widely used in robotic bending cells; EPB works with high-end robot manufacturers such as Kawasaki, Kuka, and Yaskawa to ensure that their machines are well-suited for high-speed robotic bending applications.

Our press brakes work well in customer's workshop

Customer come from different countries for cooperation and inspection