Hydraulic Swing Beam Shearing Machine Sheet Metal Cutting Machine Price

Jiangsu Hoston Machine Tools Co., Ltd.- After-sales Service:Online Support

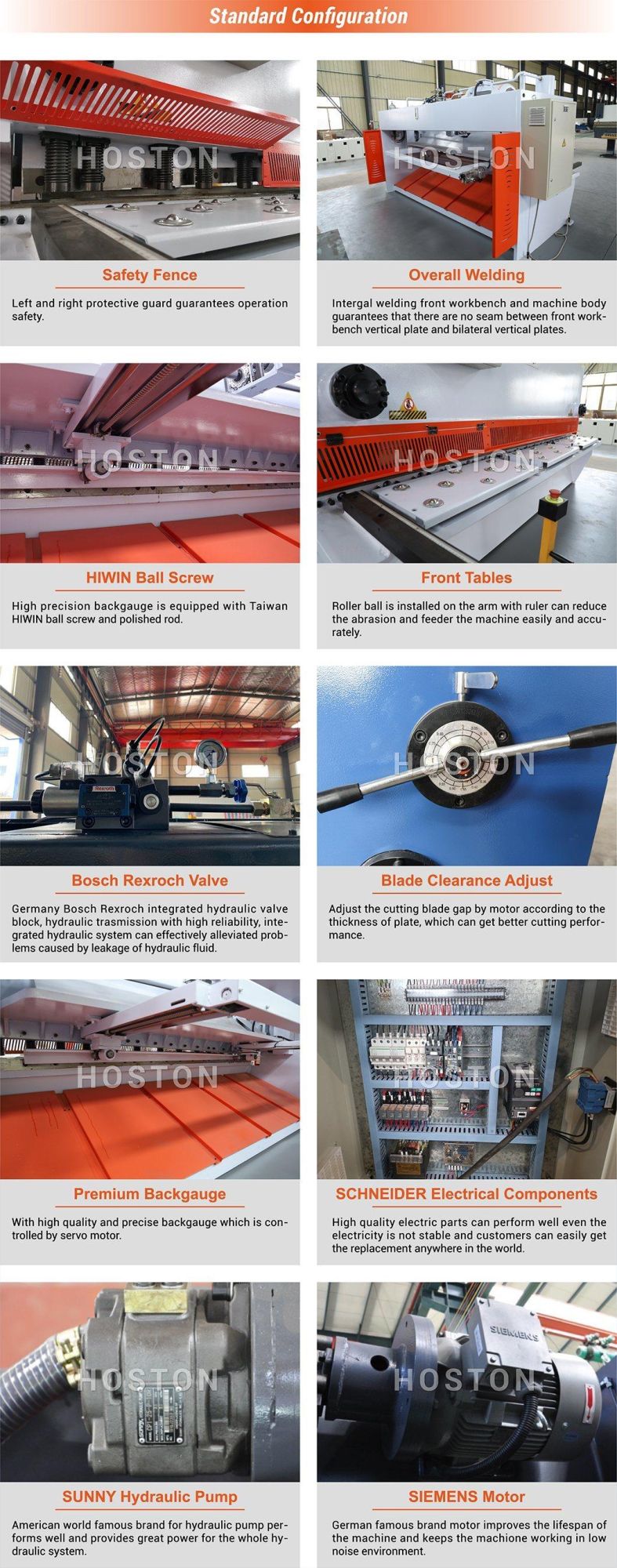

- Automation:Automatic

- Certification:CE, ISO 9001:2000

- Condition:New

- Warranty:1 Year

- Electrical Components:France Schneider

Base Info

- Model NO.:HBS-6*3200

- Pump:Japan Sumitomo

- Valve:Italy Atos

- Motor:Siemens

- Seal:Japan Nok

- Type:Metal Cutting Machine

- Application:Machinery & Hardware

- Type for Cutting Machine:Hydraulic Cutting Machine

- Ball Screw:Hiwin

- Cutting Length:3200mm

- Cutting Thickness:6mm

- Throat Depth:100mm

- Transport Package:Film Protective Package

- Specification:CE, ISO, SGS, BV

- Trademark:Hoston

- Origin:Jiangsu Province

- HS Code:846239900

- Production Capacity:1000 Sets Per Month

Description

Basic Info.

Model NO. HBS-6*3200 Pump Japan Sumitomo Valve Italy Atos Motor Siemens Seal Japan Nok Type Metal Cutting Machine Application Machinery & Hardware Type for Cutting Machine Hydraulic Cutting Machine Ball Screw Hiwin Cutting Length 3200mm Cutting Thickness 6mm Throat Depth 100mm Transport Package Film Protective Package Specification CE, ISO, SGS, BV Trademark Hoston Origin Jiangsu Province HS Code 846239900 Production Capacity 1000 Sets Per MonthProduct Description

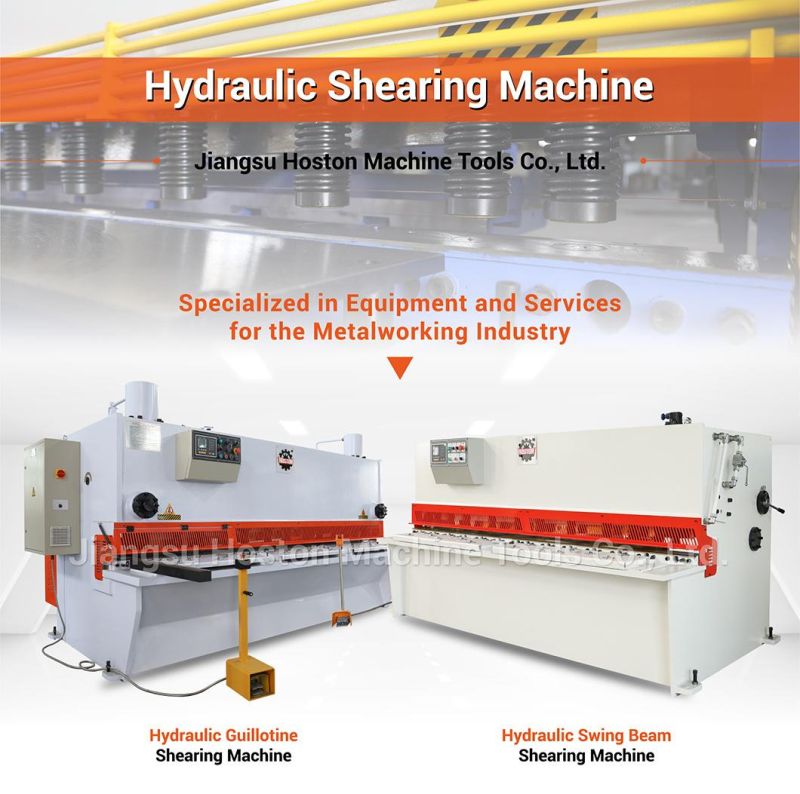

HOSTON hydraulic swing beam shear can cut all kind of metal sheet to maintain the highest production capacity with maximum precision and quality.

HOSTON guillotine shear is available with a broad series of standard equipment but it is possible, at any moment, to add optional equipment according to requirement.

Shearing machine performance characteristics

The frame structure of the shearing machine adopts all-steel welding; the four-corner and eight-sided right-angle guide rails have high precision, good rigidity and hydraulic preloading. The hydraulic system adopts two-way plug-in integrated valve, and can be equipped with stroke digital display, photoelectric protection device and mobile workbench. The shearing machine has double-action function of upper slider and lower hydraulic pad, and the working pressure stroke can be pressed within the specified range. The process requires adjustment, and the operation is simple and centralized using buttons.

1. The shearing machine adopts the overall welded frame structure and is subjected to vibration aging treatment. The machine tool has good rigidity, high precision and good precision retention.

2. The shearing machine adopts a three-point support shaft rolling guide rail. The upper tool holder performs rolling without gaps between the rolling guide rails, and the handwheel can be rotated to adjust the service life of the blade.

3, movable blade support and four-blade long blade, easy to adjust the blade gap uniformity, improve the cutting quality and extend the blade life.

4. The shearing machine adopts the serial type cylinder synchronous system. The machine is evenly stressed. By adjusting the flow of the series cylinder, the shear angle can be easily adjusted to meet the needs of different shearing plates.

5. The shearing machine adopts a motorized back gauge device and an electronic counter to facilitate adjustment of the position of the back gauge.

Swing Beam Shearing Machine Technical Parameter

| Type | Cutting Thickness (mm) | Cutting length (mm) | Travel Times (times/min) | Backgauge Range (mm) | Cutting Angle | Throat Depth (mm) | Powe (KW) | Dimension LxWxH (mm) |

| HBS-4x2500 | 4 | 2500 | 22 | 550 | 1.5° | 100 | 5.5 | 3020x1490x1500 |

| HBS-4x3200 | 4 | 3200 | 19 | 550 | 1.5° | 100 | 5.5 | 3720x1490x1550 |

| HBS-6x2500 | 6 | 2500 | 18 | 550 | 1.5° | 100 | 7.5 | 3030x1665x1620 |

| HBS-6x3200 | 6 | 3200 | 15 | 550 | 1.5° | 100 | 7.5 | 3730x1665x1620 |

| HBS-6x6000 | 6 | 6000 | 8 | 750 | 1.5° | 100 | 11 | 6580x2400x2100 |

| HBS-8x2500 | 8 | 2500 | 14 | 550 | 1.5° | 100 | 7.5 | 3040x1665x1620 |

| HBS-8x3200 | 8 | 3200 | 12 | 550 | 1.5° | 100 | 7.5 | 3740x1665x1620 |

| HBS-10x2500 | 10 | 2500 | 11 | 550 | 2° | 100 | 11 | 3050x1750x1700 |

| HBS-10x3200 | 10 | 3200 | 10 | 550 | 2° | 100 | 11 | 3750x1800x1750 |

| HBS-10x6000 | 10 | 6000 | 6 | 750 | 2° | 100 | 18.5 | 6650x2100x2300 |

| HBS-12x2500 | 12 | 2500 | 12 | 750 | 2° | 100 | 15 | 3100x2000x1850 |

| HBS-12x3200 | 12 | 3200 | 10 | 750 | 2° | 100 | 15 | 3900x2000x1850 |

| HBS-16x2500 | 16 | 2500 | 11 | 750 | 2.5° | 100 | 18.5 | 3150x2200x1900 |

| HBS-16x3200 | 16 | 3200 | 9 | 750 | 2.5° | 100 | 18.5 | 3950x2200x1900 |

| HBS-16x6000 | 16 | 6000 | 4 | 750 | 2.5° | 100 | 22 | 6850x3100x2700 |

| HBS-20x2500 | 20 | 2500 | 8 | 750 | 2.5° | 100 | 22 | 3200x2180x2000 |

| HBS-20x3200 | 20 | 3200 | 7 | 750 | 2.5° | 100 | 22 | 4000x2220x2100 |

| HBS-25x2500 | 25 | 2500 | 7 | 750 | 3° | 120 | 37 | 3220x2280x2200 |

| HBS-25x3200 | 25 | 3200 | 6 | 750 | 3° | 120 | 37 | 4020x2330x2220 |

| HBS-30x3200 | 30 | 3200 | 5 | 750 | 3.5° | 120 | 45 | 4050x2450x2360 |

Guilotine Shearing Machine Technical Parameter

| Type | Cutting thickness (mm) | Cutting length(mm) | Travel Times (times/min) | Back Gauge Distance (mm) | Cutting Angle | Throat Depth (mm) | Power (KW) | Dimension LxWxH (mm) |

| HGS-6x2500 | 6 | 2500 | 18 | 550 | 1.5° | 100 | 7.5 | 3100x1600x2050 |

| HGS-6x3200 | 6 | 3200 | 15 | 550 | 1.5 | 100 | 7.5 | 3800x1600x2050 |

| HGS-6x4000 | 6 | 4000 | 12 | 550 | 1.5° | 100 | 7.5 | 4600x1600x2100 |

| HGS-6x6000 | 6 | 6000 | 8 | 750 | 1.5° | 100 | 11 | 6600x1900x2500 |

| HGS-8x2500 | 8 | 2500 | 14 | 550 | 1.5° | 100 | 7.5 | 3100x1600x2000 |

| HGS-8x3200 | 8 | 3200 | 12 | 550 | 1.5° | 100 | 7.5 | 3800x1600x2000 |

| HGS-8x4000 | 8 | 4000 | 10 | 550 | 1.5° | 100 | 11 | 4600x1600x2100 |

| HGS-8x6000 | 8 | 6000 | 6 | 750 | 1.5° | 100 | 15 | 6600x1900x2500 |

| HGS-10x2500 | 10 | 2500 | 11 | 550 | 2° | 100 | 11 | 3100x1700x2100 |

| HGS-10x3200 | 10 | 3200 | 10 | 550 | 2° | 100 | 11 | 3800x1700x2100 |

| HGS-10x4000 | 10 | 4000 | 9 | 750 | 2° | 100 | 15 | 4600x1700x2200 |

| HGS-12x2500 | 12 | 2500 | 12 | 750 | 2° | 100 | 15 | 3200x1800x2250 |

| HGS-12x3200 | 12 | 3200 | 10 | 750 | 2 | 100 | 15 | 3900x1800x2250 |

| HGS-12x4000 | 12 | 4000 | 8 | 750 | 2° | 100 | 18.5 | 4700x1800x2400 |

| HGS-12x6000 | 12 | 6000 | 5 | 750 | 2° | 100 | 22 | 6800x2000x2600 |

| HGS-16x2500 | 16 | 2500 | 11 | 750 | 2.5° | 100 | 18.5 | 3400x2100x2500 |

| HGS-16x3200 | 16 | 3200 | 9 | 750 | 2.5° | 100 | 18.5 | 4100x2100x2500 |

| HGS-16x4000 | 16 | 4000 | 6 | 750 | 2.5° | 100 | 22 | 4900x2100x2600 |

| HGS-16x6000 | 16 | 6000 | 4 | 750 | 2.5° | 100 | 22 | 7000x2300x2800 |

| HGS-20x2500 | 20 | 2500 | 8 | 750 | 2.5° | 100 | 22 | 3400x2100x2600 |

| HGS-20x3200 | 20 | 3200 | 7 | 750 | 2.5° | 100 | 22 | 4100x2100x2600 |

| HGS-20x4000 | 20 | 4000 | 6 | 750 | 2.5° | 100 | 30 | 4900x2200x2700 |

| HGS-25x2500 | 25 | 2500 | 7 | 750 | 3° | 120 | 37' | 3500x2200x2700 |

| HGS-25x3200 | 25 | 3200 | 6 | 750 | 3° | 120 | 37 | 4200x2200x2800 |

| HGS-25x4000 | 25 | 4000 | 5 | 750 | 3° | 120 | 37 | 5000x2300x2900 |

| HGS-30x2500 | 30 | 2500 | 6 | 750 | 3.5° | 120 | 45 | 3600x2300x2800 |

| HGS-30x3200 | 30 | 3200 | 5 | 750 | 3.5° | 120 | 45 | 4300x2300x2900 |

| HGS-30x4000 | 30 | 4000 | 5 | 750 | 3.5° | 120 | 45 | 5100x2400x3000 |