CNC Servo Press Brake Da52s for C355 Metal Bending

LZK CNC Machine Tool (Anhui) Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Certification:RoHS, ISO 9001:2000, ISO 9001:2008, CE, UL

- Automation:Automatic

- Suitable for:Rubber, Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel, Mild Steel. Aluminum

- Type:Press Brake

Base Info

- Model NO.:HPB 100T3200

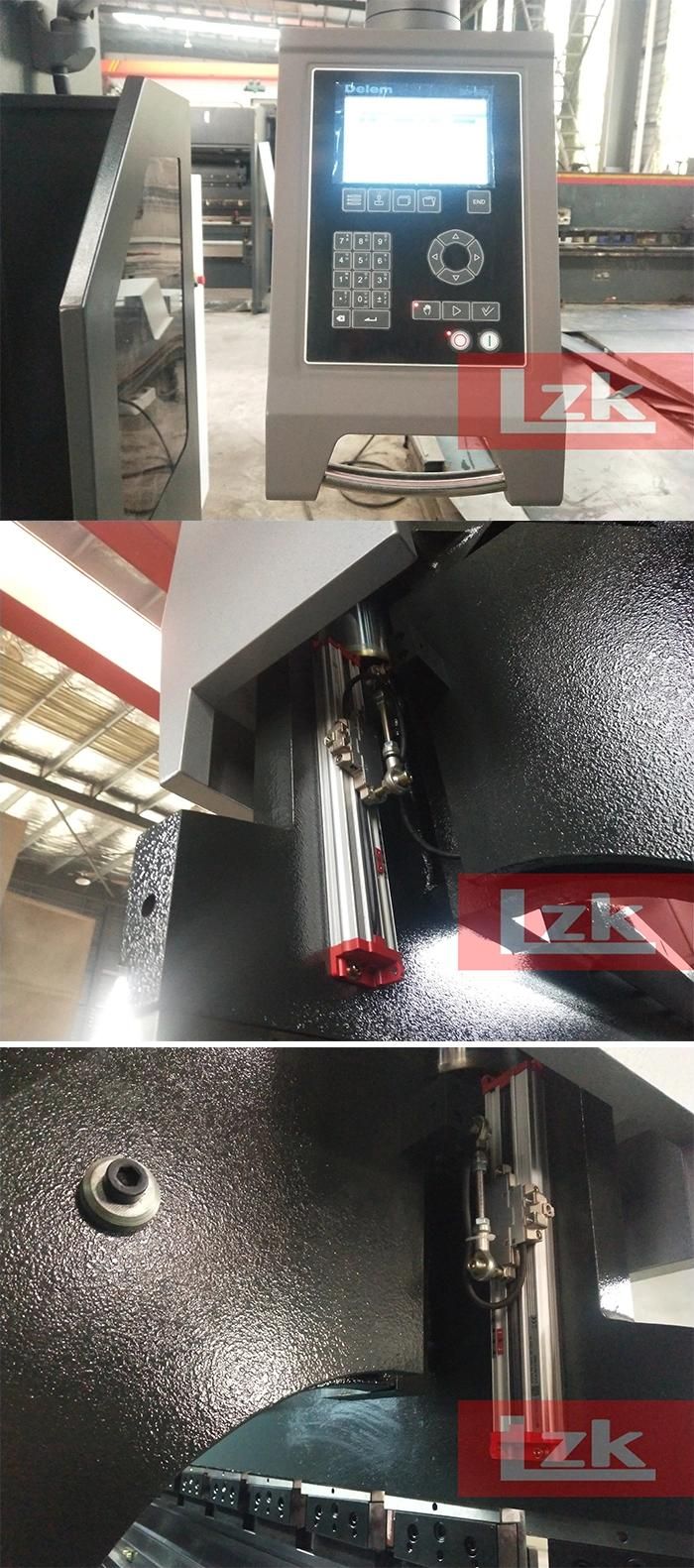

- Control Panel:Delem Da52s

- Max Bending Width:3200mm

- Max Bending Thickness for 3m Sheet:4mm

- Backgauge Distance:500mm

- Pole Distance:2600mm

- Slide Stroke:200mm

- Max Opening Height:480mm

- Throat Depth:400mm

- Front Support Arms:2 Pieces

- Backgauge Fingers:2 Pieces

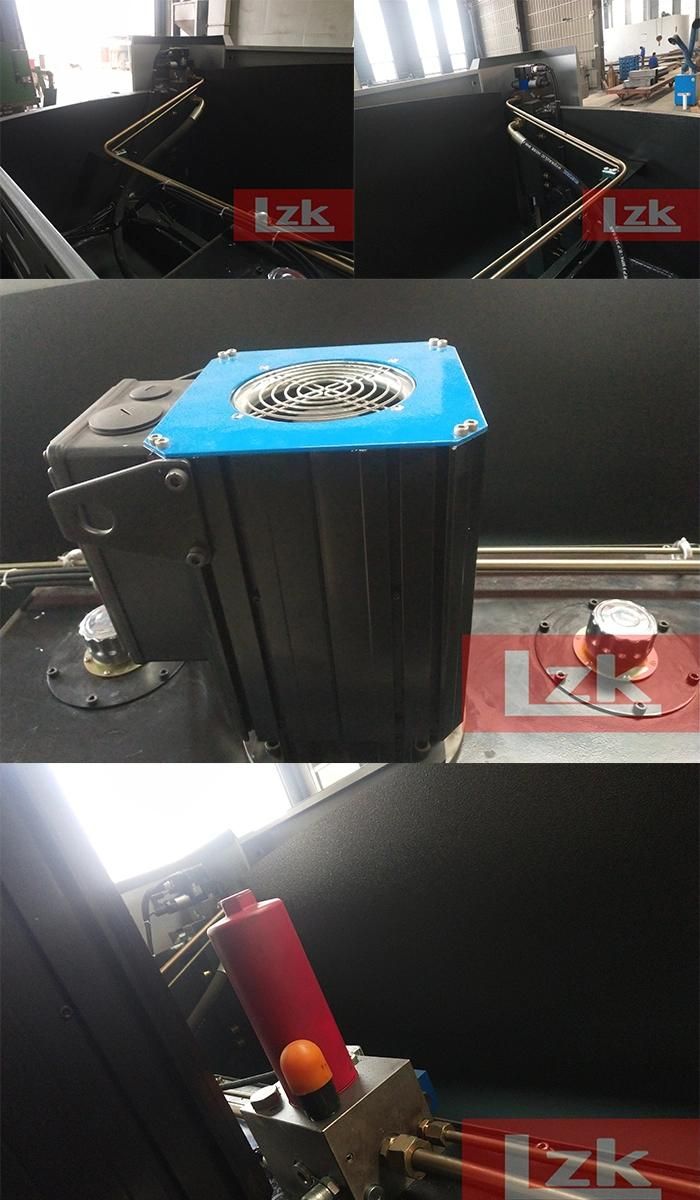

- Main Motor:Servo Motor

- Main Electrical Components:Schneider

- Hydraulic System:Bosch Rexroth

- Oil Pump:Sunny

- Punch and Die:One Set with Machine for Free

- Transport Package:40hq

- Specification:3850x1850x2600

- Trademark:LZK

- Origin:Maanshan, China

- HS Code:8462219000

- Production Capacity:100 Set,Month

Description