MB9 4+1 Axes Mechanical Crowning Esa S630 Hydraulic Press Brake 100t3200

LZK CNC Machine Tool (Anhui) Manufacturing Co., Ltd.- Waterproof Rating:IPX-8

- Warranty:2-year

- Certification:CE

- Automation:Automatic

- Suitable for:Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel, Mild Steel, Galvanized Sheet

- Type:Press Brake

Base Info

- Model NO.:MB9 100T3200

- CNC System:Esa S630

- Axes:Y1, Y2, X, R and Crowning

- Main Motor:Siemens

- Electrics:Schneider

- Hydraulic Valve:Bosch-Rexroth

- Backgauge:600mm

- Backguage Control:Servo Motor

- Ball Screw and Linear Guide:Taiwan Hiwin

- Power:7.5kw

- Weight:8.5t

- Transport Package:as You Require

- Specification:3500x1580x2400mm(LxWxH)

- Trademark:Jiashida Machine

- Origin:China

- HS Code:8462219000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. MB9 100T3200 CNC System Esa S630 Axes Y1, Y2, X, R and Crowning Main Motor Siemens Electrics Schneider Hydraulic Valve Bosch-Rexroth Backgauge 600mm Backguage Control Servo Motor Ball Screw and Linear Guide Taiwan Hiwin Power 7.5kw Weight 8.5t Transport Package as You Require Specification 3500x1580x2400mm(LxWxH) Trademark Jiashida Machine Origin China HS Code 8462219000 Production Capacity 100 Sets/MonthProduct Description

MB9 4+1 Axes Mechanical Crowning Esa S630 Hydraulic Press Brake 100t3200

| MB9 Oil and Electricity Mixed Hydraulic CNC Press Brake Features: |

| The BiD-SVP two-way pump electrohydraulic servo system was used. BiD-SVP is Bi-Drectional Servo Pump bidirectional servo pump. The BiD-SVP bi-directional pump electro-hydraulic servo system has the advantages of high energy saving, minimization of unnecessary work, and improvement of production efficiency. It can directly reduce the electricity bill and greatly reduce the use of hydraulic oil; it can greatly reduce CO2 emissions and reduce environmental pollution. . |

| Each machine is equipped with energy saving, which can help customers to achieve high efficiency and energy saving production. |

| Brand-new industry design combined with modern aesthetic concept, high-quality production technology, simple appearance. |

| Latest high-frequency responding hydraulic control technology, faster, more efficient and accurate. |

| Heat treatment of the rack, rigidity optimization verification on entire machine and the application of mechanical compensation structure jointly ensure the bending precision of MB9 series PRESS BRAKES. |

| Brand Quick Clamping Device |

| The clamping interface of the European mould |

| With the fine tuning wedge, adjustable fixture to ensure the effective use of height between flatness requirements. |

| Front Supports |

| Can be moved along the linear guide in the worktable direction |

| South Korea Foot Pedal Switch |

| Emergency buttom |

| Two black small hand shank to control the finger block to move left and right |

| Foot press up and down |

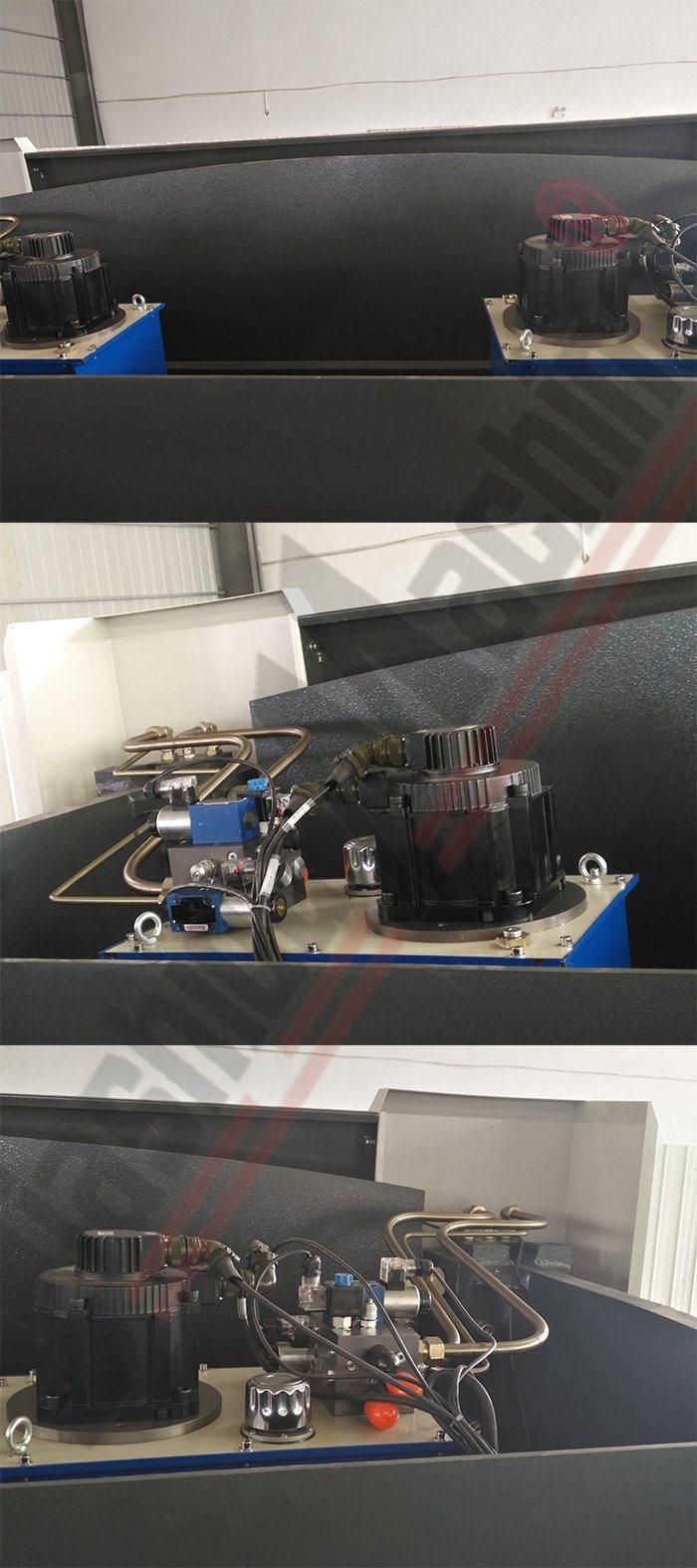

| Mechanical Compensation/Crowning |

| --The deflection compensation mechanism adopts the compensation structure of the mechanical disturbance table. Numerical control automatic calculation and control |

| --When working, the working force of the compensation workbench is equal to that of the main oil cylinder, which produces a convex curve which compensates for the deformation of the worktable and slider during operation. |

| --Each group is composed of several groups of 3D surfaces with different slopes. It makes up for the shortcomings of the traditional hydraulic compensation in compensating the blind area, and the compensation curve is closer to the slide plate deformation curve, thus greatly improving the machining accuracy of the bending machine. |

| ESA-S630 CNC system features: |

| Can be used for electro-hydraulic bending machine, double-acting bending machine 10 inch touch screen 2D graphics programming function Fill-in programming mode, automatic calculation of bending force and deflection compensation Direct control of multiple servo valves without any external amplifier All programs, molds and parameters can be saved to USB flash drive via USB interface Standard 4+1 axis control |

| France Schneider Electrics |

| Stable performance, long life service |

| Bi-Drectional Servo Pump Advantages: |

| Minimize overflow losses. |

| Stepless speed regulation. Adjustment range 0 to maximum. |

| No proportional valve control reduces throttling losses |

| Accurate fuel demand distribution, optimized by dynamic servo motor speed. |

| No idle power: The servomotor can be switched off when no flow or pressure is required. |

| Unique, normally open fill valve design for hydraulic compensation control. |

| Compact design makes installation easier. |

| The difficulty of machining cylinders is reduced and the cost is reduced. |

| For machine tool builders, changes are minor and manufacturing is easier |

| Italy GIVI Grating Ruler |

| Slider position signals can be feedback to CNC system by bilateral gratings, then CNC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider Y1, Y2 running on the same frequency, maintaining the parallel state of the worktable. |

| Backgauge |

| With X and R axis |

| Taiwan Hiwin Ball Scress and Linear Guide to main the high precision |

| Estun Servo Motor controls backguage |

| Two Finger Blocks move along the beam electronically |

MORE MACHINE DETAILS, PLEASE SEND US YOUR INQIURY, THANKS.