70mm Saving Time on Tool Changes Servo CNC Press Brake

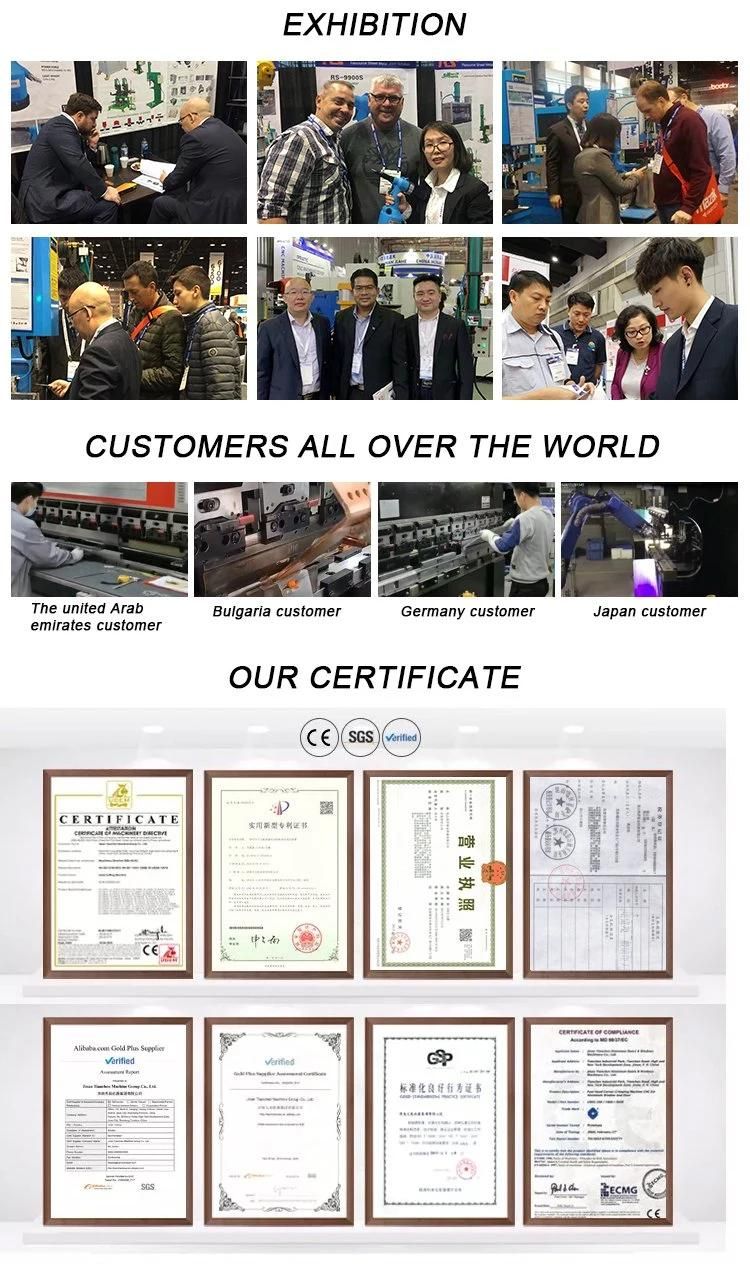

RSM Machinery Co.,Ltd.- After-sales Service:Online Video Support

- Waterproof Rating:IPX-3

- Warranty:2-year

- Condition:New

- Certification:RoHS, ISO 9001:2000, ISO 9001:2008, CE

- Automation:Automatic

Base Info

- Suitable for:Aluminum, Alloy, Stainless Steel

- Type:Hydraulic Bending Machine

- Capacity:8 T

- Stroke:70mm

- Bending Length:20mm

- Back Gauge Stroke:100mm

- Total Power:4.7kw

- Number of Axis:2

- Total Weight:0.7t

- Transport Package:Export Standard Wooden Box

- Specification:CE

- Trademark:RS

- Origin:China

- HS Code:8462219000

- Production Capacity:10 Set,Month

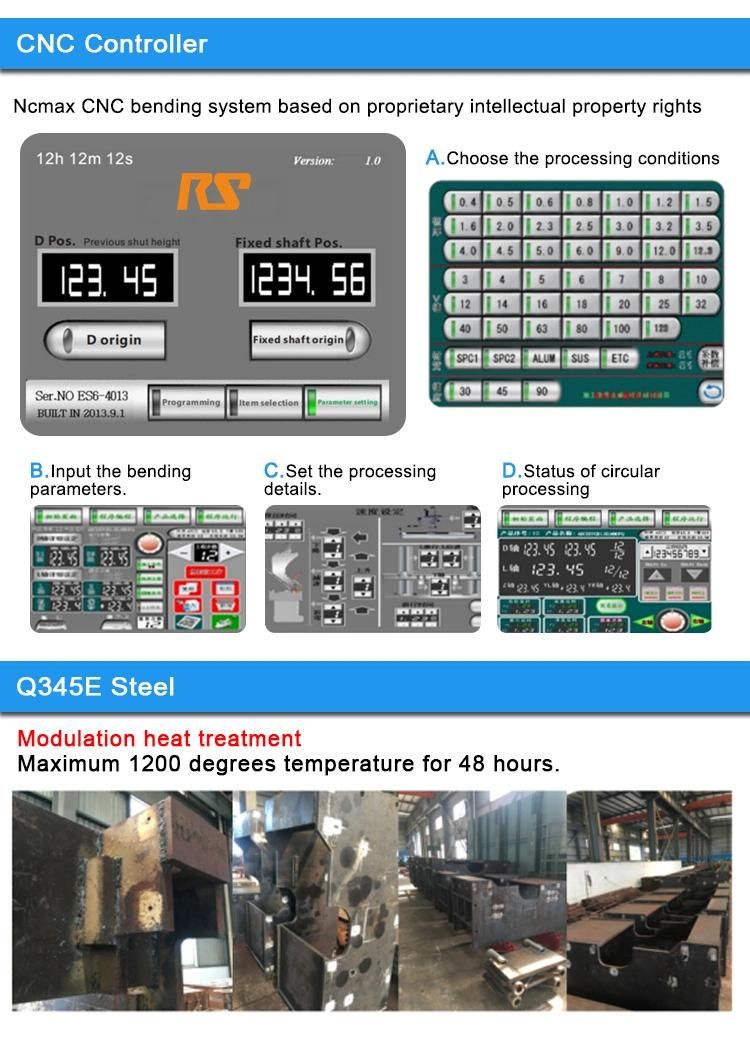

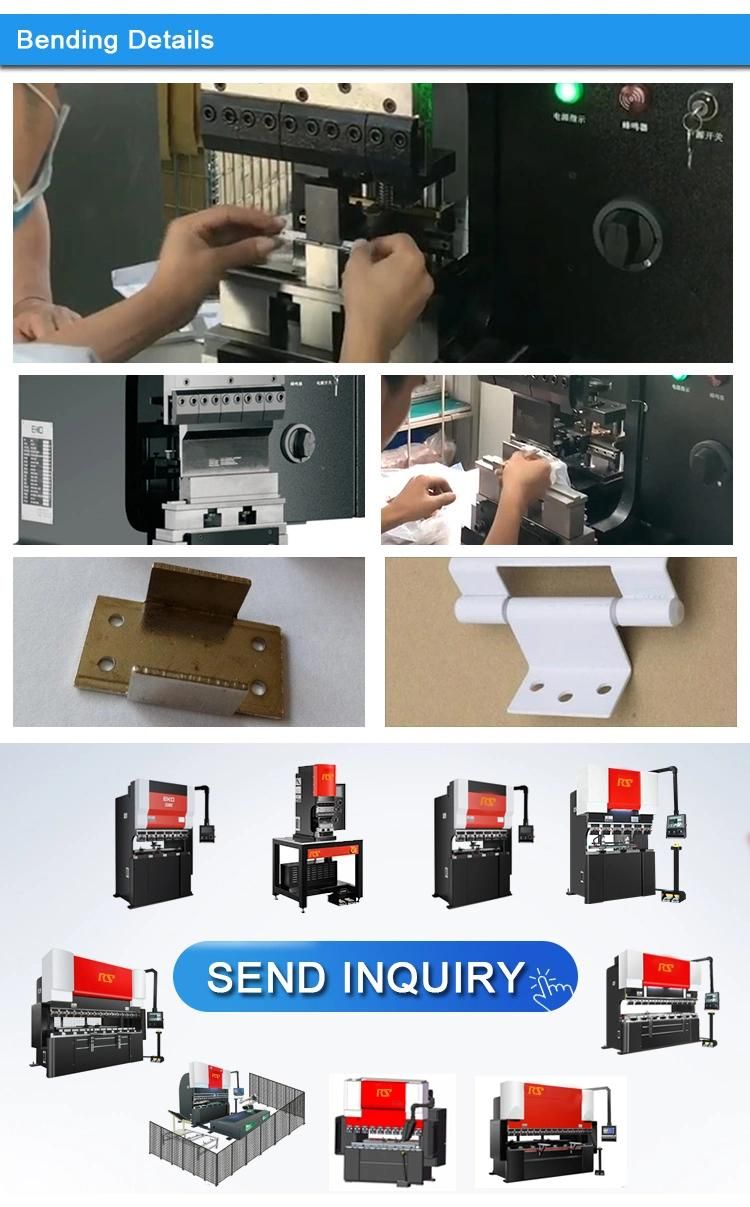

Description

FAQ

1. Do you only offer this one product?

A: No, We offer various models of full servo press brakes. ES802 is our hot selling model.

2.How do you guarantee quality?

A: We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments.

3.Is the product easy to maintain?

A: In order to ensure good performance and precision of equipment during production, guarantee product quality, reduce maintenance frequency and prolong the service life, it is required to strictly carry out daily inspection items, e.g., dust and rust removal, moisture prevention, lubrication, screw tightening, etc.