Hydraulic Bus Bar Punching Machine, Nc Busbar Processing Machinery

Suzhou Kiande Electric Co., Ltd.- After-sales Service:Worldwide

- Waterproof Rating:IPX-0

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2008

- Automation:Semi-Automatic

Base Info

- Model NO.:KDEQ-02-167

- Suitable for:Copper, Aluminum, Alloy

- Type:Hydraulic Bending Machine

- Transport Package:Plywood Case

- Specification:1200mm*800mm*2500mm

- Trademark:Kiande

- Origin:China

- HS Code:8414809090

- Production Capacity:10 Set Per Month

Description

Basic Info.

Model NO. KDEQ-02-167 Suitable for Copper, Aluminum, Alloy Type Hydraulic Bending Machine Transport Package Plywood Case Specification 1200mm*800mm*2500mm Trademark Kiande Origin China HS Code 8414809090 Production Capacity 10 Set Per MonthProduct Description

Copper bar gas-hydraulic bending machine / Digital Bus Bar Punching MachineDigital bus bar punching machine is used to punch the two ends of busbar in one time to guarantee parallelism between busbar profile and conductor. This parallelism ensures the reliable connection between conductor and joint which can control joint temperature rising. Key point is that machine can adjust the rebound coefficient according to conductor's material and width. Rebound coefficient varies by bending or different conductor width and this kind of adjustment can guarantee the parallelism.

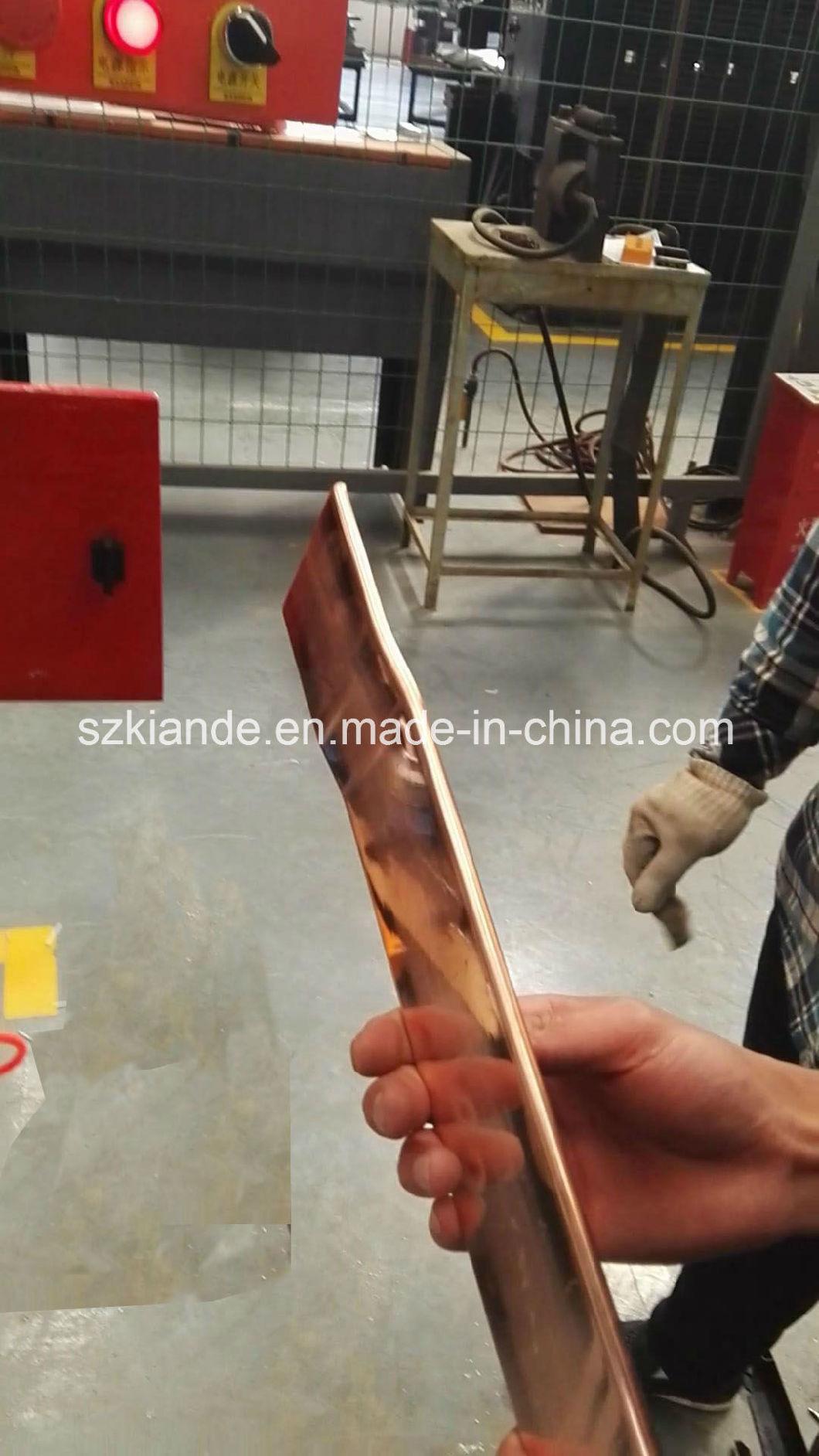

The copper or aluminum bar hydraulic bending machine is used to bend the copper or aluminum bar once to deform the bar as requred angle.

Specification:

| No. | Parameters |

| Model | KD-YYJ-40(50)T |

| Bending Power Type | Hydraulic and pneumatic hybrid |

| Pressure | 40T or 50T, Max. 80T |

| Die | Fast die change |

| Workplace Size | L450mm*W340mm |

| Control Mode | Digital control |

| Air Source | 0.6MPa |

| Power | 220~230VAC 50~60Hz 80W |

| Equipment Dimension | L680mm* W580mm* H2600mm |

1. Suitable for bus bar of straight length type or L or Z type, length 500~3000mm, width less than 250mm and thickness no bigger than 6mm;

2. Working efficiency: 1m/minute;

3. Standard configuration: one piece air and hydraulic bending machine, one set of frame;

4. Automation level: semi-automation;

Advantages:

1. Once deforming enables accurate deforming angle;

2. Integral die and die core for easy change;

3. Automatic pressurize and return controlled by PLC;

Configuration:

| No. | Component Name | Quantity |

| 1 | Air cylinder | 1set |

| 2 | PLC | 1set |

| 3 | Housing | 1set |

| 4 | Electric control system | 1set |

| 5 | Electromagnetic valve | 1set |

| 6 | Oil-water separator | 1set |

| 7 | Electric component | 1set |

| 8 | Moulding | 1set |

| 9 | Frame | 1set |

| 10 | Air pressure | |

| 11 | Voltage | |

| 12 | Power |