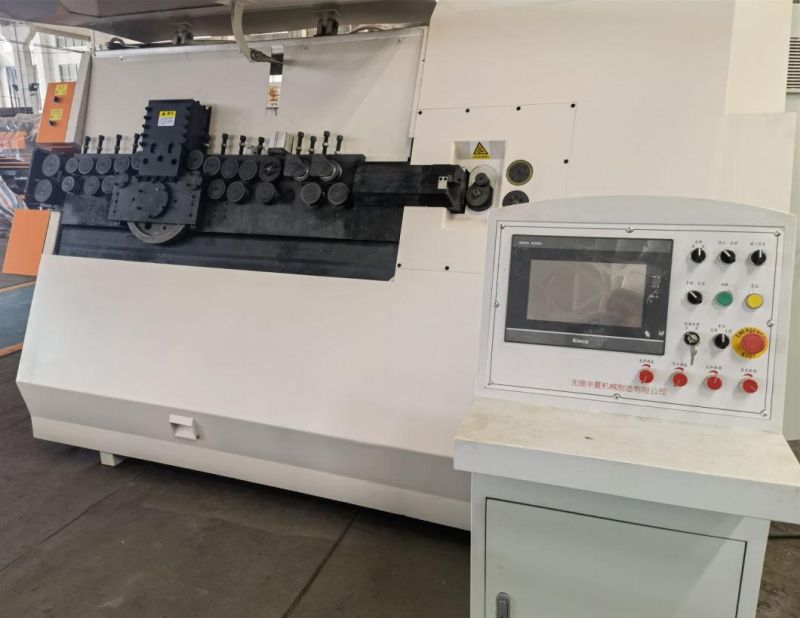

CNC Steel Wire Stirrup Bender Machine From Coil

Wuxi Huaxia Machine Manufacture Co., Ltd.- After-sales Service:Always Technical Support

- Waterproof Rating:IPX-8

- Warranty:1-year

- Condition:New

- Certification:ISO 9001:2000, ISO 9001:2008, CE

- Automation:Automatic

Base Info

- Suitable for:Alloy, Carbon Steel, Stainless Steel

- Type:Cnc Bending Machine

- Rebar Size:6-12mm

- Two Rebars:6-10mm 2PCS

- Installation Power:32kw

- Feeding Speed:80m,Min

- Bending Speed:1220°,Sec

- Cutting Precision:+,-1mm

- Bending Precision:+,-1′

- Bending Angle:+,-180°

- Drive:Three Servo Motors

- Control:Independent Standing Panel

- Straightening:Big Curved Wheel

- Receiver Arm:Automatic

- Receiving Bracket:for Straight Bars

- Raw Material:Wire Rebar Coils

- Maker:Huaxia Machinery

- Transport Package:Film Wrapping and Wooden Box

- Specification:3800x1400x2300mm

- Trademark:HX

- Origin:Wuxi, China

- HS Code:8462219000

- Production Capacity:200sets

Description

Basic Info.

Suitable for Alloy, Carbon Steel, Stainless Steel Type Cnc Bending Machine Rebar Size 6-12mm Two Rebars 6-10mm 2PCS Installation Power 32kw Feeding Speed 80m/Min Bending Speed 1220°/Sec Cutting Precision +/-1mm Bending Precision +/-1′ Bending Angle +/-180° Drive Three Servo Motors Control Independent Standing Panel Straightening Big Curved Wheel Receiver Arm Automatic Receiving Bracket for Straight Bars Raw Material Wire Rebar Coils Maker Huaxia Machinery Transport Package Film Wrapping and Wooden Box Specification 3800x1400x2300mm Trademark HX Origin Wuxi, China HS Code 8462219000 Production Capacity 200setsProduct Description

Our CNC Rebar Stirrup Bending Machines make stirrups from steel wire coils(rebar or rod), includes wire coil payoff, rebar straightening, bending and cutting, can continuously bend stirrups under heavy load.We make the hoop bending machines for hundreds of sets and we know very well how to make critical parts in high precision, our stirrup bender not only good looking outside, but also durable working inside, our customers continuously order from our factory.

Our automatic CNC stirrup bending machine is intelligent CNC system and strong straightening, bending and cutting structure, ensure continuous heavy duty working

Characters and advantages

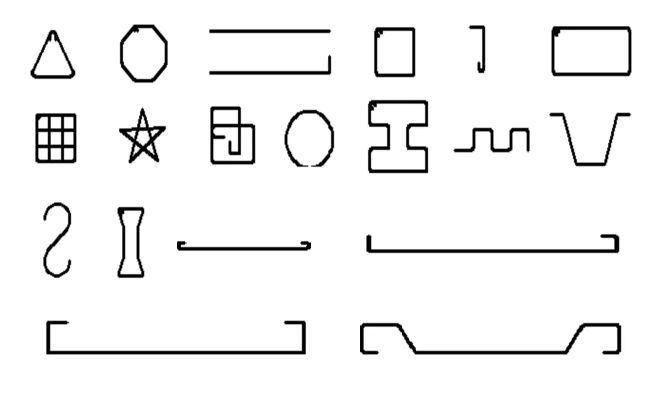

1/All kinds of stirrups(bending shapes) can be bent by the bending rotor.

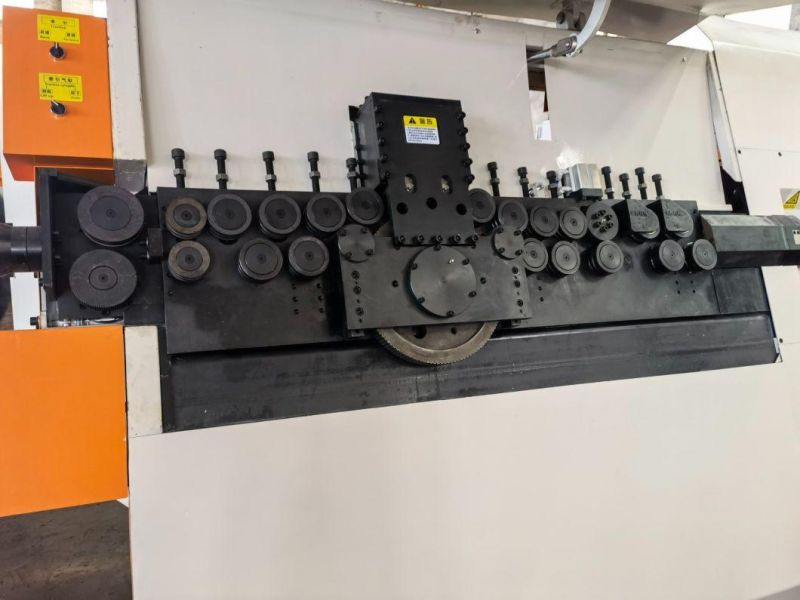

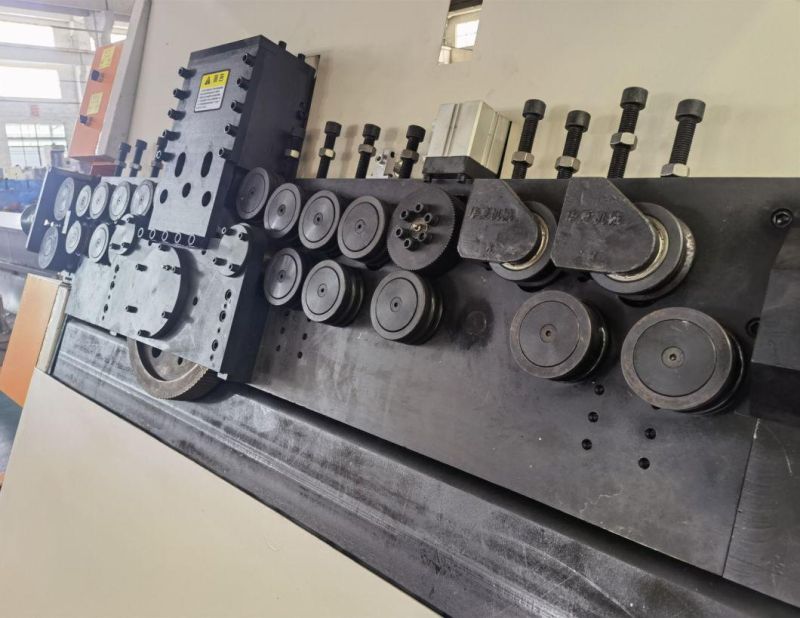

2/ Strong bending capacity: Φ10mm x 2pcs HRB400 rebars bending.

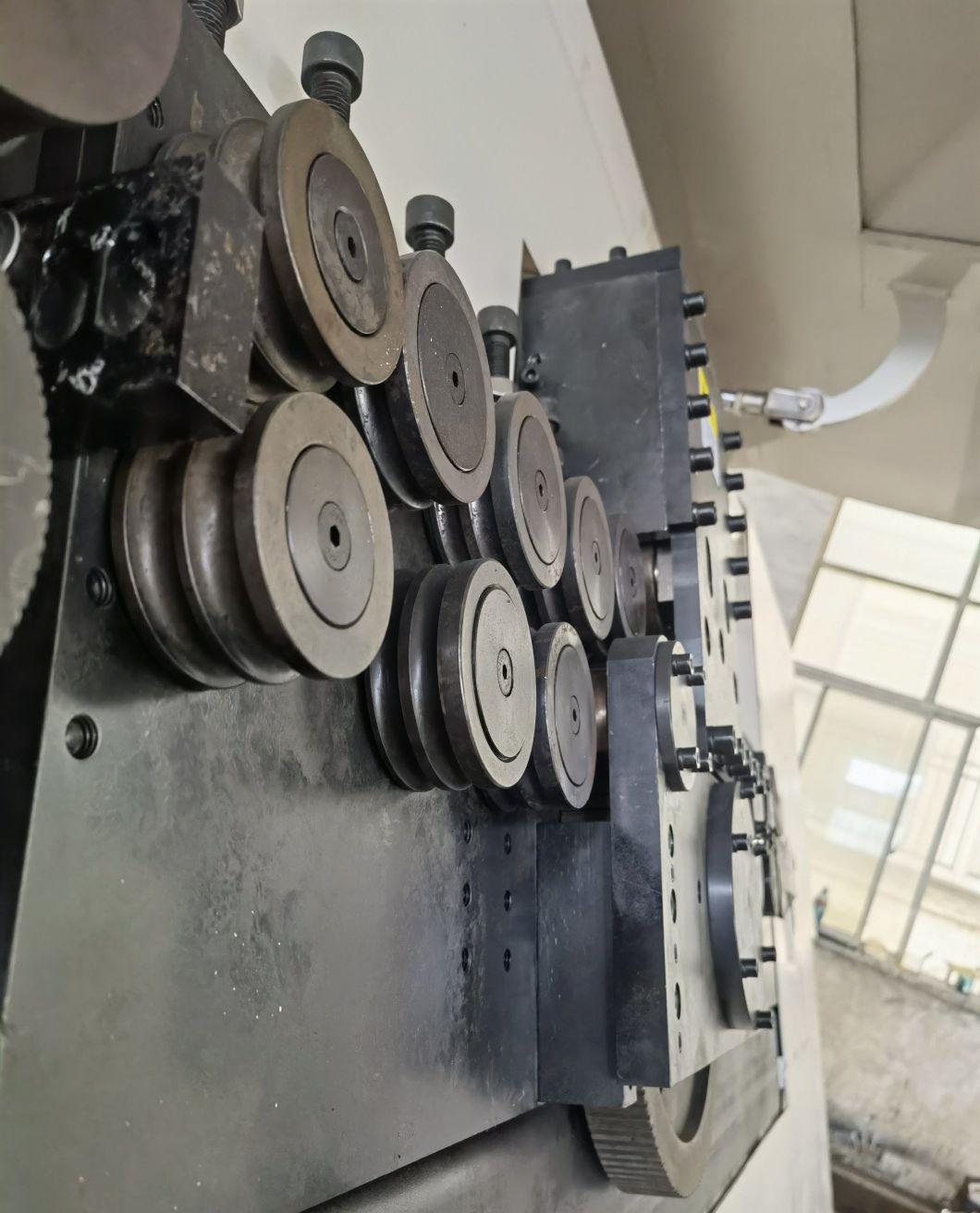

3/Curved line Straightening system

Compared with traditional straight line straightening method, curved line straightening system can solve axial deflection issue, this way, the straightening effect is better and the output stirrup will have smaller open mouth and flatter shape.

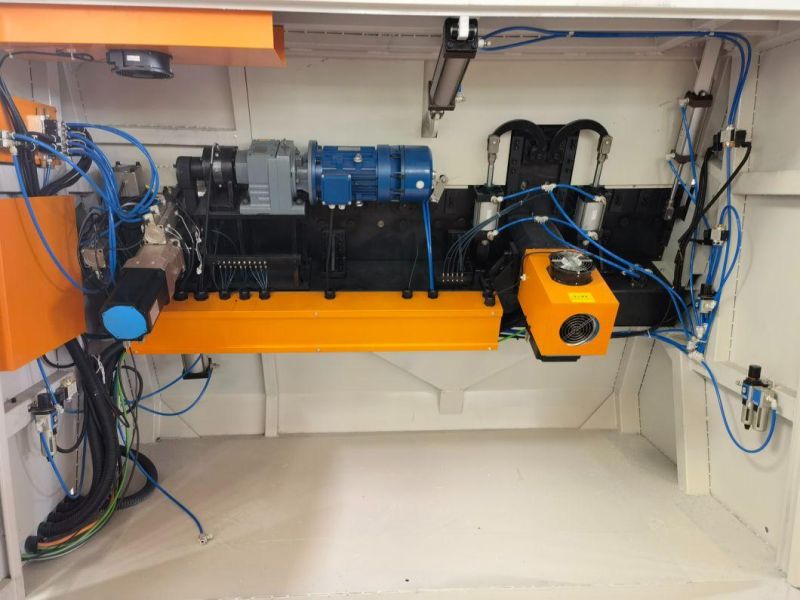

4/ Double servo motors and double planetary reducer

The transmission of planetary reducer is high efficiency and good stability, cooperating with high performance servo motor. The maintenance is very convenient and much lower cost.

5/Remote control and automatic feeder to realize threading, one person can easily watch the feeding rebar and adjust its direction, fast and convenient.

6/Fast cutting by Brake motor and reducer

The cutting is realized by one 4KW AC brake motor and reducer, big cutting force can cut two pcs rebar easily. Solid state relay control gives fast cutting reaction, the cutter stops at fixed position by proximity switch.

7/Concentrative oiling device ensure good lubrication of each critical point, as well as pneumatic oiling gun. Easy lubrication easy maintenance.

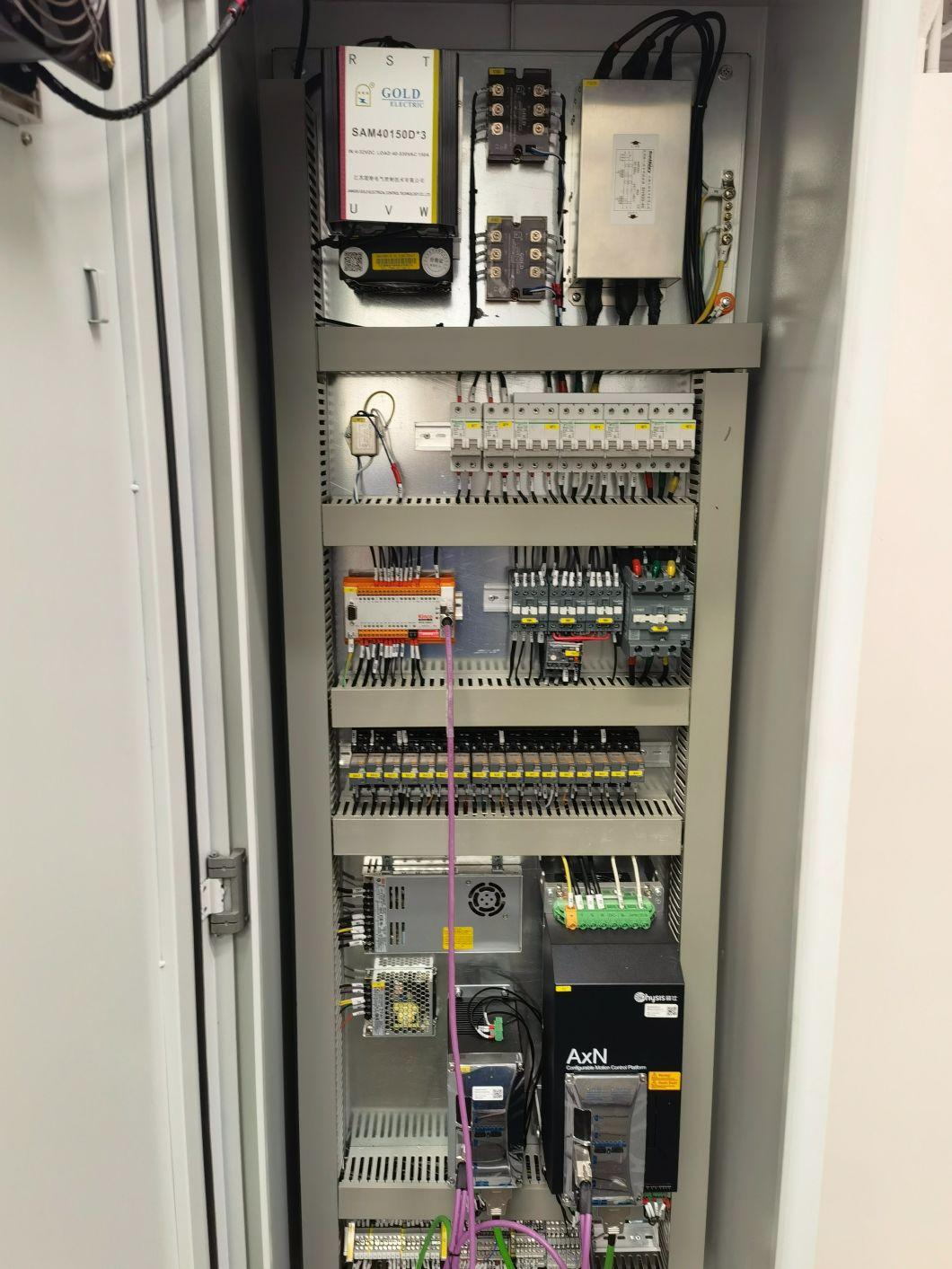

8/ Independent electric operator cabinet

standing beside the bender, this prevents iron dust and dirty oil from damaging the control and improves the electric control efficiency.

High performance servo motor driver, famous electric parts, Airtac pneumatic, Kinco touch screen. The whole system ensure excellent and stable performances.

Four switches: Feeding speed, bending speed, angle adjusting, support rack adjusting

9/ 10inch screen, fast reaction and very stable.

Easily switch multi tasks, can select data from USB.

Monitor circuit to realize auto check out faults

Show the bending trend while editing bending shape diagrams, this makes editing easy and no mistake.

Save a lot of bending diagrams.

Double systems ensure normal work when some electric parts are broken.

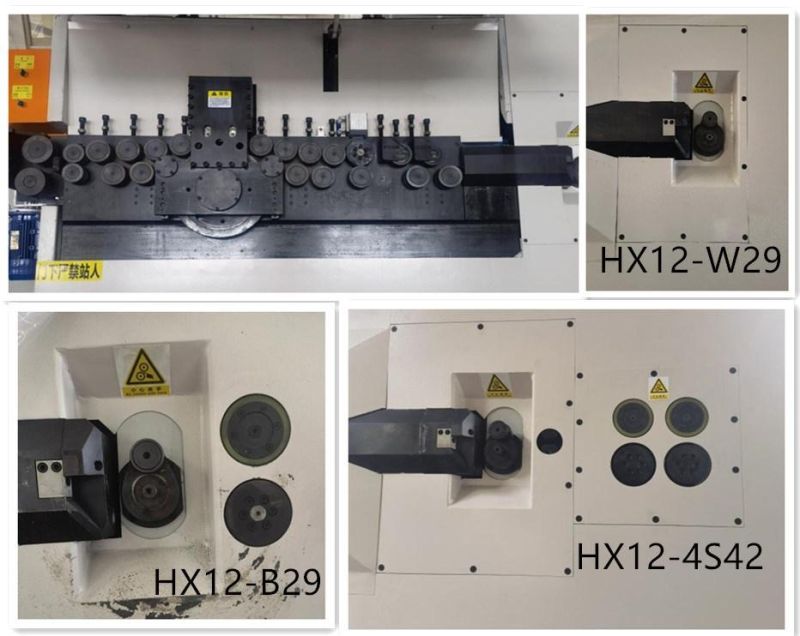

10/ Moreover, the WB29-4S42 has four wheels for rebar open hoop bending, two rubber wheels and two active wheels. Drive of two active wheels are planetary reducer and servo motor and gear transmission. The backward feeling lengths can be multi sides bending, the back sending lengths can be easily set on touch screen, then the wheels send forward the bent rebar to stacker.

Parameters

| Models | HX12-W29 | HX12-B29 | HX12-4S42 |

| Single rod/wire(HRB400) | Φ6-12mm | Φ6-12mm | Φ6-12mm |

| Double rods/wires(HRB400) | Φ6-10mm | Φ6-10mm | Φ6-10mm |

| Bending angle | +/-180° | +/-180° | +/-180° |

| Diametr of center pin | 20-30 mm | 20-30 mm | 20-30 mm |

| Max feeding speed | 80m/min | 80m/min | 80m/min |

| Max angle bending speed | 1220°/sec | 1220°/sec | 1220°/sec |

| Cutting Length precision | ±1mm | ±1mm | ±1mm |

| Angle bending precision | ±1° | ±1° | ±1° |

| Power consumption | 5KW/h | 5KW/h | 5KW/h |

| Number of wire pieces | ≤2 | ≤2 | ≤2 |

| Installation poer | 29KW | 32KW | 32KW |

| Shape of stirrup Module of stirrup shapes data and individual edit stirrup shape | all kinds of shapes without backward wheels for ligament shape | all kinds of shapes, two wheels for one side back feeding | all kinds of shapes, four wheels for muilti sides back feeding |

| Machine weight exclude bracket | 2800KG | 2800KG | 2800KG |

| Work temperature | -5ºC~40ºC | -5ºC~40ºC | -5ºC~40ºC |

| Machine Dimensions | 3800x1400x2300mm | 3800x1400x2300mm | 3800x1400x2300mm |

| Machine color | White + Orange | White + Orange | White + Orange |

Wuxi Huaxia Machine Manufacture Co., Ltd. is located in Wuxi, close to Shanghai. As a scientific and technological innovation enterprise specializing in R& D, production and sales of intelligent steel rebar, wire rod processing equipment, we own 27 national utility model patents, 1 national invention patent. Our main products include intelligent CNC steel stirrup bending machines, CNC straightening and cutting machines, CNC five- head bending machine, wire rod drawing machines and other intelligent rebar processing equipment.

Our equipment product is widely used in real estate, high-speed railway, highway, bridge tunnel, electric power engineering and other building construction. The company continues to introduce high value-added product technology to provide customers with high-performance technical equipment. Products are exported to dozens of countries and regions such as Angola, Algeria, Iran, Jordan, and get praises from domestic and foreign customers.

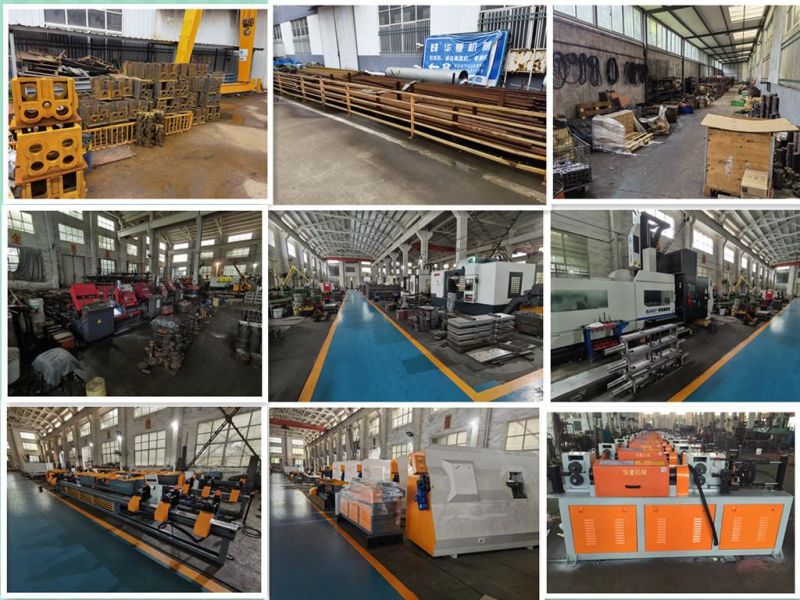

Now we have 2 factories, the total area 12,000 square meters, our processing capacity is powerful, a numerical control center, CNC lathe, CNC laser cutting equipment, robot welding equipment, wire cutting equipment, milling machine, grinding machine and other diversified processing equipment, every part is processed and tested before assembling, our equipment product precision is high and our machine quality is good.

We pursue excellence, harmony, people-oriented, scientific management. Welcome you to consult us!

FAQ:

1/ Q: Are you a factory or a trading company?

A: We are a professional steel rebar processing equipment manufacturer, we have two factories of 12000 square meters. We design, make and sell independently, you will get direct factory price and engineering support from us.

2/ Q: Are the parts of equipment produced by yourself?

A: All the parts drawings are designed by our engineers, then the whole production goes with the drawings. Except for the standard parts like motors, bearings, valves, all the other parts are made by our factory under ISO9001 management, thus we can guarantee machine quality and stability.

3/. Q: How long is the delivery time?

A: Our factory is mass production, and we can deliver within 15 days; if there are some customized parts included, we can secure within 30-45 days delivery time.

4/ Q: Why the online price is just a range?

A: As we have a lot of models, and the configuration of each machine is varying. We will equip each machine according to the specific requirements of customer, therefore can not give a fixed price. The price range is a reference.

5/ Q: Company development history and profile

A: Our company is built in 2000. specializing to produce rebar wire rod processing equipment, standard or non-standard custom. Over 20 years experiences and famous in the industry. Now we make all parts by CNC centers and robot equipment, the machine precision is very good.

6/ Q: Would you like to have agents abroad?

A: We welcome various collaborations with customers, agents are one of our most important customers, if construction equipment agents overseas want to cooperate with us, we are very pleased to support in machine supply and services.

7/ Q: Do you accept OEM orders?

A: We would like to make OEM equipment, and surely will satisfy the customers who have own brands.

8/ Q: Can we visit your factory?

A: Welcome you to visit us anytime you like, our factory locates in E'hu Town, Xishan District, Wuxi City, very near to Shanghai.