W11 6 X 3200 Bending Machine Rolling Machine hydraulic 3 Rollers Machine

Wmt Cnc Industrial Co., Ltd.- Condition:New

- Certification:RoHS, ISO 9001:2008, CE, CS

- Automation:Semi-Automatic

- Suitable for:Rubber, Copper, Aluminum, Carbon Steel, Stainless Steel

- Type:Roller-Bending Machine

- Power:Mechanical

Base Info

- Model NO.:W11 6x3200

- Machine:Metal Sheet Forming

- Application:Machinery & Hardware

- Type for Fold-Bending Machine:Electrical Bending Machine

- Plate Rolling Machine:3 Roller Symmetrical

- Transport Package:Fumigated Exporting Standard Wooden Case

- Specification:CE, SGS, ISO9001: 2000

- Trademark:WMT or customized logo

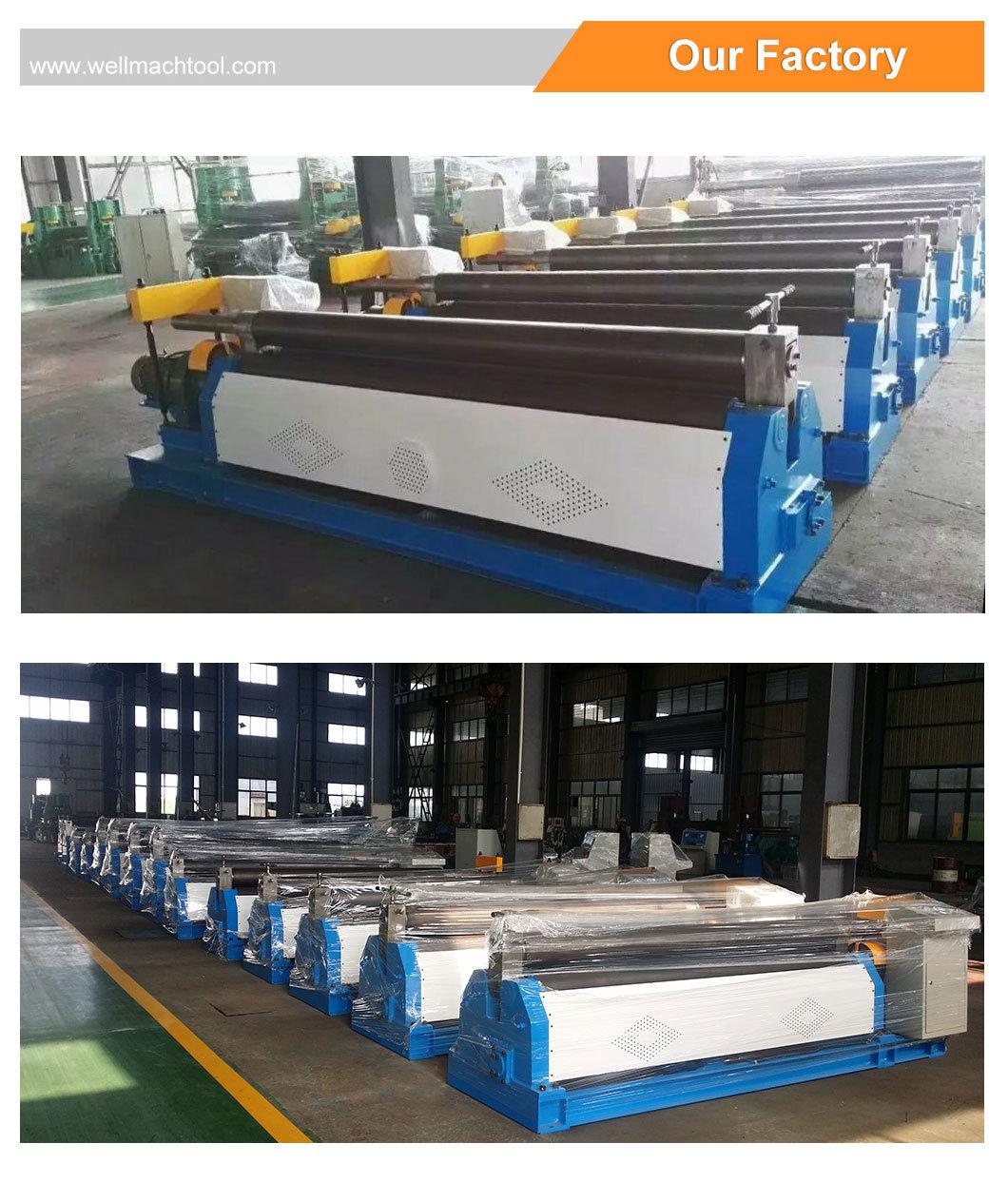

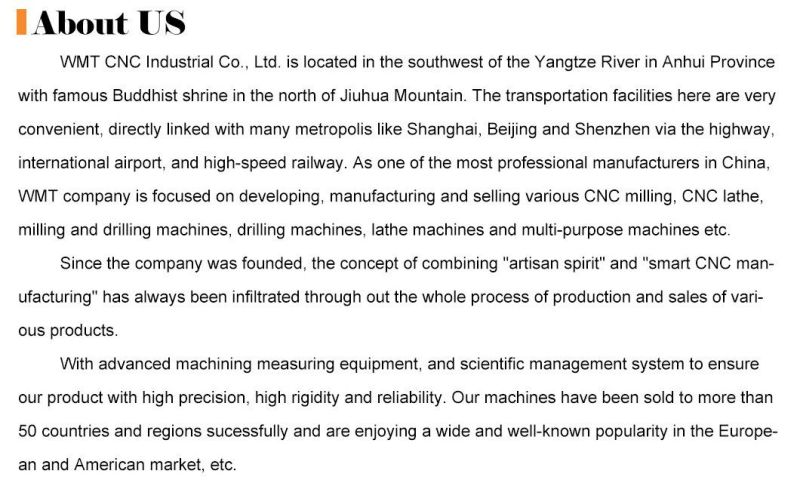

- Origin:Chizhou, Anhui, China

- HS Code:8462299000

- Production Capacity:20 Sets Monthly

Description

Basic Info.

Model NO. W11 6x3200 Machine Metal Sheet Forming Application Machinery & Hardware Type for Fold-Bending Machine Electrical Bending Machine Plate Rolling Machine 3 Roller Symmetrical Transport Package Fumigated Exporting Standard Wooden Case Specification CE, SGS, ISO9001: 2000 Trademark WMT or customized logo Origin Chizhou, Anhui, China HS Code 8462299000 Production Capacity 20 Sets MonthlyProduct Description

Main performance:

The machine adopts 3-roller symmetrical structure with the upper roller moving vertically in the center between the two lower rollers,which is achieved through the drive of the screw,the nut,the worm and the lead screw.The two roller rotates,and provides the plate materials with torque throught the engagement of the output gear of the moderator with the gear of the lower rollers.The disaadvantage of the machine is that the ends of the plate materials need to have the help from other equipment for pre-bending.

Main specification:

Specification | Max Thickness of Coiled Plate | Max Width of Coiled Plate | Yielding Limit of Sheet Metal | Coiling Speed | Min Full Loading Diameter of Coiled Plate | Diameter of Top shaft | Diameter of Bottom shaft | Central distance between Bottom Shafts | Motor Power | Overall dimensions |

| mm | mm | MPa | m/min | mm | mm | mm | mm | Kw | mm | |

| W11-4×1500 | 4 | 1500 | 245 | 5 | 300 | 150 | 140 | 185 | 3 | 2900×720×1000 |

| W11-6×1500 | 6 | 1500 | 245 | 5 | 450 | 160 | 160 | 250 | 4 | 2900×720×1000 |

| W11-6×2000 | 6 | 2000 | 245 | 4.5 | 450 | 185 | 170 | 250 | 5.5 | 3650×820×1050 |

| W11-6×3200 | 6 | 3200 | 245 | 4.5 | 380 | 240 | 180 | 280 | 7.5 | 4850×1100×1100 |

| W11-8×2000 | 8 | 2000 | 245 | 4.5 | 400 | 230 | 180 | 300 | 5.5 | 3700×820×1050 |

| W11-8×2500 | 8 | 2500 | 245 | 4.5 | 600 | 230 | 180 | 300 | 7.5 | 4150×1100×1100 |

| W11-12×2000 | 12 | 2000 | 245 | 4.5 | 600 | 240 | 180 | 280 | 7.5 | 36500×1100×1100 |

| W11-12×2500 | 12 | 2500 | 245 | 4.5 | 600 | 260 | 220 | 340 | 11 | 4200×920×1200 |

| W11-12×3000 | 12 | 3000 | 245 | 4 | 700 | 280 | 250 | 360 | 11 | 4900×1300×1300 |

| W11-16×2000 | 16 | 2000 | 245 | 4 | 650 | 260 | 220 | 340 | 11 | 3700×920×1200 |

| W11-16×2500 | 16 | 2500 | 245 | 4 | 700 | 300 | 250 | 360 | 15 | 4400×1300×1300 |

| W11-16×3200 | 16 | 3200 | 245 | 4 | 850 | 340 | 280 | 440 | 18.5 | 5300×14000×1400 |

| W11-20×2000 | 20 | 2000 | 245 | 4 | 700 | 280 | 250 | 360 | 15 | 3900×1300×1300 |

| W11-20×2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 280 | 440 | 18.5 | 4600×1400×1400 |

| W11-25×2000 | 25 | 2000 | 245 | 4 | 850 | 330 | 270 | 430 | 18.5 | 4100×1400×1400 |

| W11-25×2500 | 25 | 2500 | 245 | 4 | 1200 | 380 | 310 | 550 | 22 | 5600×1550×2000 |

| W11-30×2500 | 30 | 2500 | 245 | 4 | 1200 | 400 | 350 | 550 | 30 | 5760×1700×2110 |

| W11-30×3000 | 30 | 3000 | 245 | 4 | 1200 | 450 | 390 | 600 | 37 | 5400×1700×2210 |